High-rigidity brittle fiber material non-destructive covering yarn and spinning method thereof and fabric

A brittle fiber and high rigidity technology, which is applied in the non-destructive covering yarn of high rigidity brittle fiber material and its spinning method and fabric field, can solve the problems of inability to effectively exert high-strength performance, affect the processing and weaving process, increase the load, etc., and achieve Avoid high-rigidity and brittle fiber breakage, excellent wearability, and avoid breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

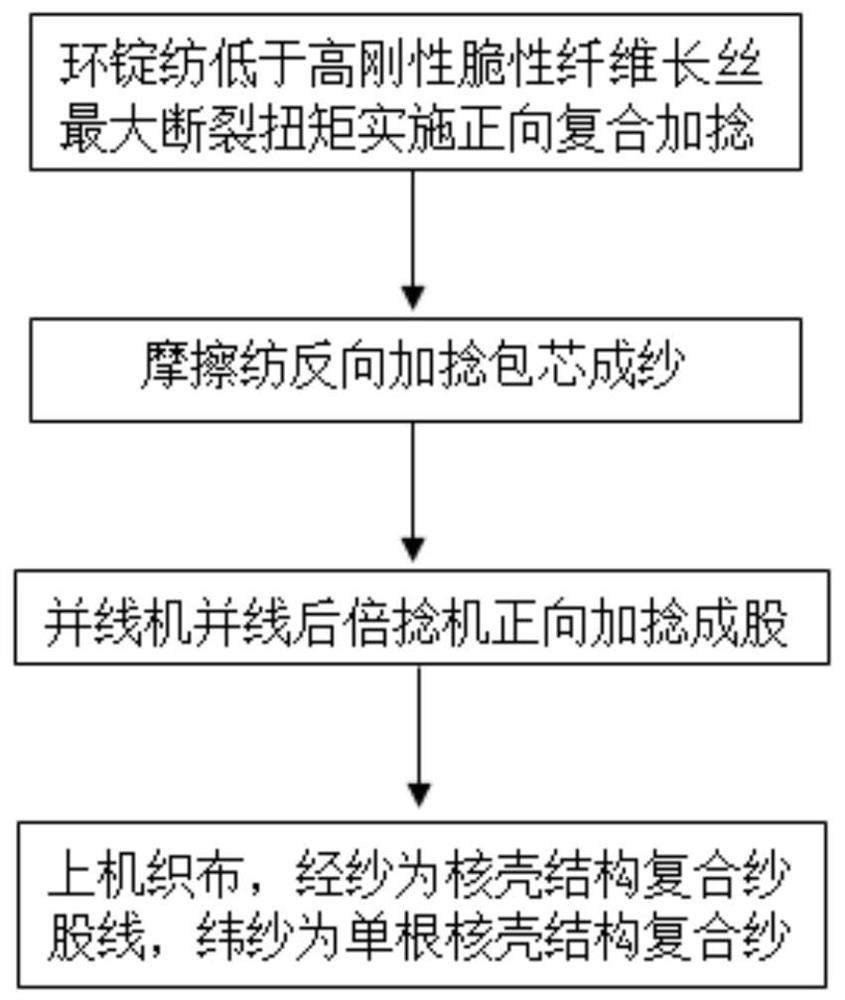

[0047] This embodiment provides a spinning method for non-destructively coated yarns with high rigidity and brittle fiber materials, comprising the following steps:

[0048] S1, flexible fiber composite twisting

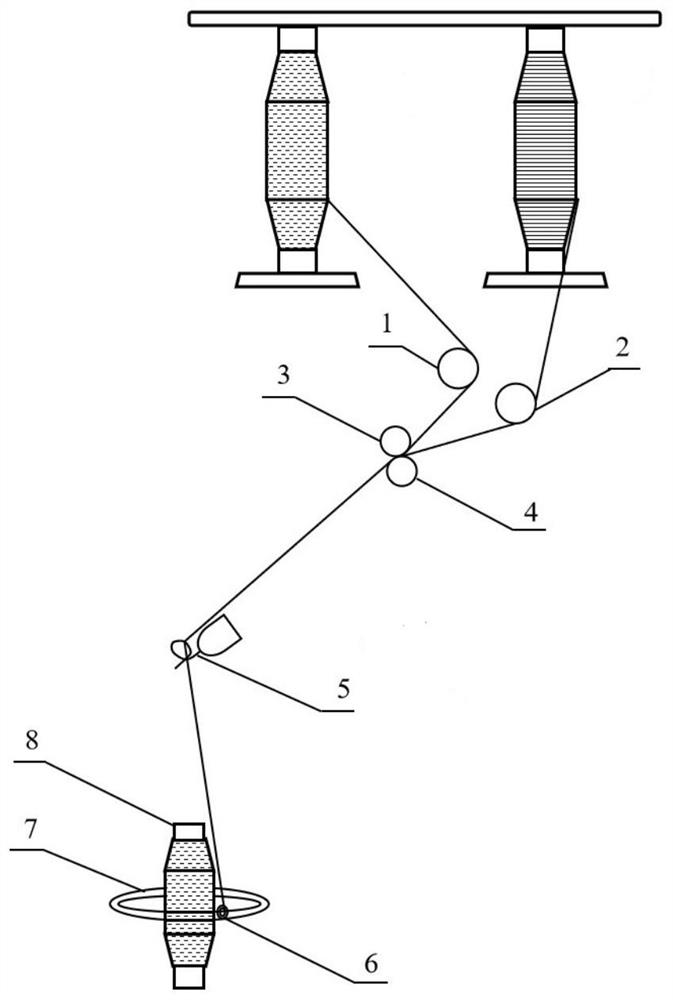

[0049] refer to figure 1 , on each drafting mechanism of the ring spinning frame, a basalt fiber filament that is unwound from the basalt fiber filament package on the active unwinding device passes through the first fixed wire guide device 1, The front nip output consisting of the front roller 3 and the front top roller 4; at the same time, the two water-soluble vinylon filaments unwound from the water-soluble vinylon filament package on the positive unwinding device pass through the second fixed type The guide wire device 2 is fed to the front jaw in parallel with the basalt fiber filament at intervals. Two water-soluble vinylon filaments are respectively located on both sides of the basalt fiber filament. The two water-soluble vinylon filaments output from the fr...

Embodiment 2

[0056] This embodiment provides a spinning method for non-destructively coated yarns with high rigidity and brittle fiber materials, comprising the following steps:

[0057] S1, flexible fiber composite twisting

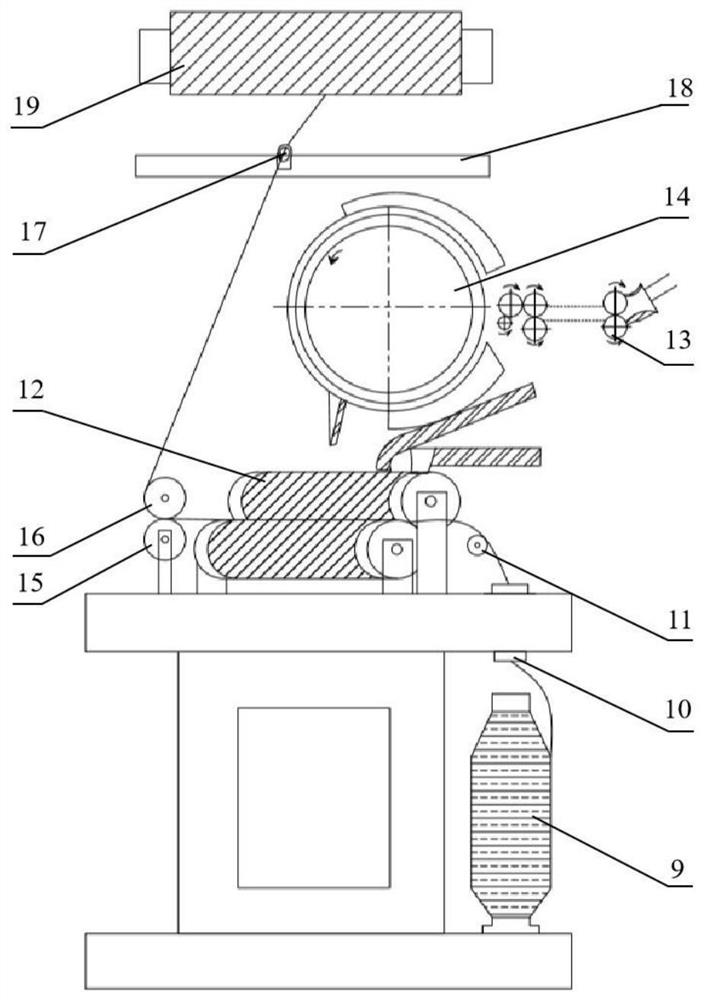

[0058] S2. Friction spinning reverse twisting core-spun yarn

[0059] S3, and twist into strands

[0060] In the above steps, steps S1 and S2 are consistent with Embodiment 1, and will not be repeated here. The specific process of step S3 is as follows:

[0061] On each winding mechanism of the doubling machine, the core-shell structure composite yarn unwound from the two friction spinning bobbin packages passes through the yarn guide of the doubling machine, the tensioner, and the winding drum of the doubling machine in sequence. , wound on the doubling bobbin to form a doubling bobbin package. Place the doubling bobbin packages in the yarn storage tanks of the two-for-one twister, and each doubling thread unwound from the doubling bobbin package passes through t...

Embodiment 3~4

[0069] Embodiments 3 to 4 respectively provide a spinning method of high-rigidity and brittle fiber materials without damaging the coated yarn. Compared with Example 2, the difference is that the type of high-rigidity and brittle fiber filaments used is changed, and Relevant spinning parameters were adjusted, and the rest of the steps were consistent with those in Example 2, and will not be repeated here. The types and spinning parameters of high rigidity and brittle fiber materials corresponding to each embodiment are shown in Table 1.

[0070] Table 1 Types of high rigidity and brittle fiber materials corresponding to Examples 3-4 and corresponding parameters

[0071]

[0072] According to the parameters listed in Table 1, Examples 3-4 respectively prepared a non-destructive covering yarn with high rigidity and brittle fiber material, which is the core-shell composite yarn strand. The mechanical properties of the high rigidity and brittle fiber materials prepared in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com