Intelligent optimization and adjustment system and method for combustion system of hedging wall/arch combustion boiler

A technology for adjusting the system and boiler combustion, applied in the direction of combustion method, control combustion, combustion equipment, etc., can solve the problem of partial coking of steam temperature deviation, achieve the effect of solving steam temperature deviation, improving uniformity, and improving the level of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

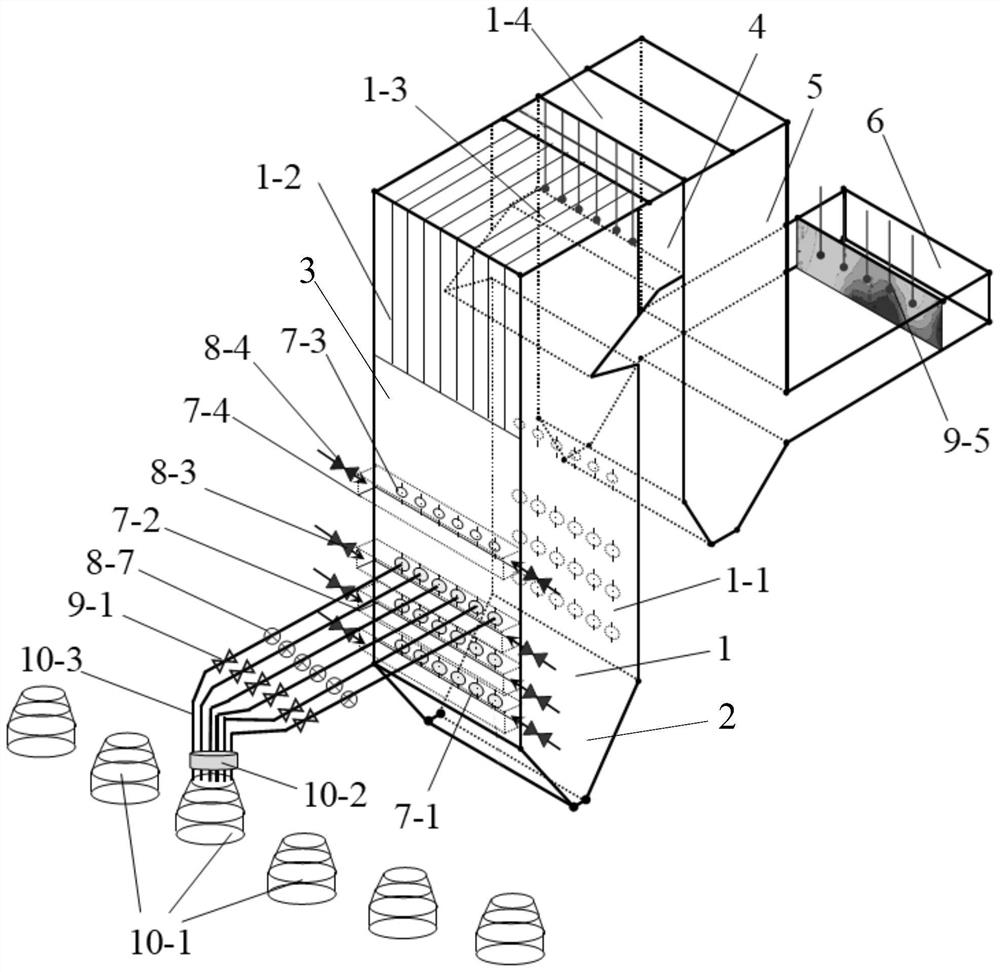

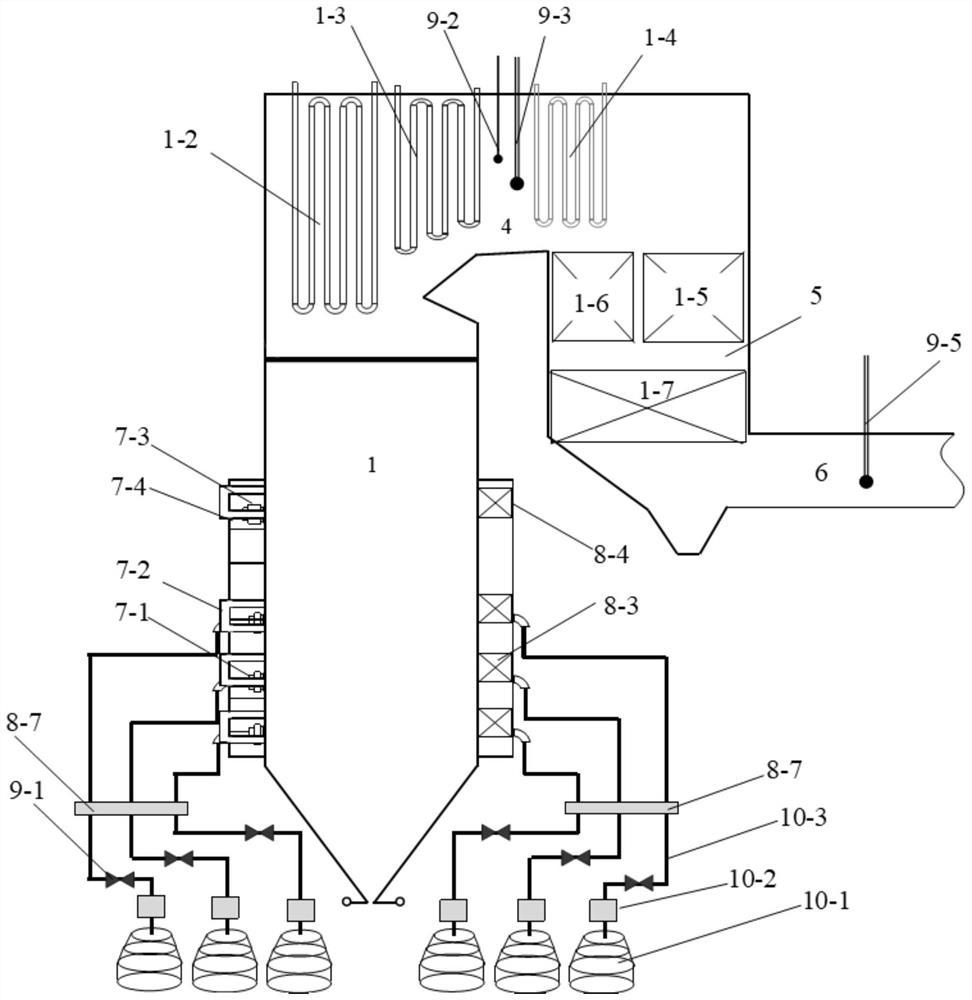

[0051] The object of this embodiment is a 600MW supercritical counter-swirl combustion boiler. The opposed swirling combustion boiler includes furnace 1, water wall 1-1, panel superheater 1-2, high temperature superheater 1-3, high temperature reheater 1-4, low temperature superheater 1-5, low temperature reheater 1-6, economizer 1-7, lower furnace 2, upper furnace 3, upper horizontal flue of furnace 4, shaft flue 5, economizer outlet flue 6, combustion system, pulverizing system. Wherein the combustion system includes a burner 7-1, a burner air box 7-2, an overburning air nozzle 7-3, and an overburning air air box 7-4. The pulverizing system includes a coal mill 10-1, a separator 10-2, and a primary air powder pipe 10-3.

[0052] The furnace 1 is composed of the front wall, the rear wall and the water-cooled walls 1-1 on both sides. The furnace 1 is divided into the lower furnace 2 and the upper furnace 3. Three layers of burners 7-1 are arranged on the front and rear walls,...

Embodiment 2

[0059] This embodiment proposes an adjustment method for the intelligent optimization and adjustment system of the combustion system of the opposing wall type / arch type combustion boiler, which mainly includes the following steps:

[0060] Step S1: Analyze and monitor the temperature and component concentration distribution of flue gas at the exit of the high-temperature superheater in the horizontal flue of the furnace, as well as the concentration distribution of the flue gas component at the flue gas side of the economizer exit, and the panel superheater, high-temperature superheater, The temperature rise of the high-temperature reheater tube panel, and the evaluation of the deviation of the combustion side in the furnace;

[0061] (1) According to the distribution of the temperature rise of the tubes at the same position of the panel superheater, high temperature superheater and high temperature reheater along the width direction of the furnace measured by the temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com