Real-time monitoring vacuum instrument

A real-time monitoring and vacuum technology, applied in vacuum gauges using ionization effect, vacuum gauges measuring medium pressure by measuring the change of thermal conductivity of medium, etc. Timeliness, equipment failure detection and other issues, to achieve the effect of reducing manual verification steps, shortening time, and improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

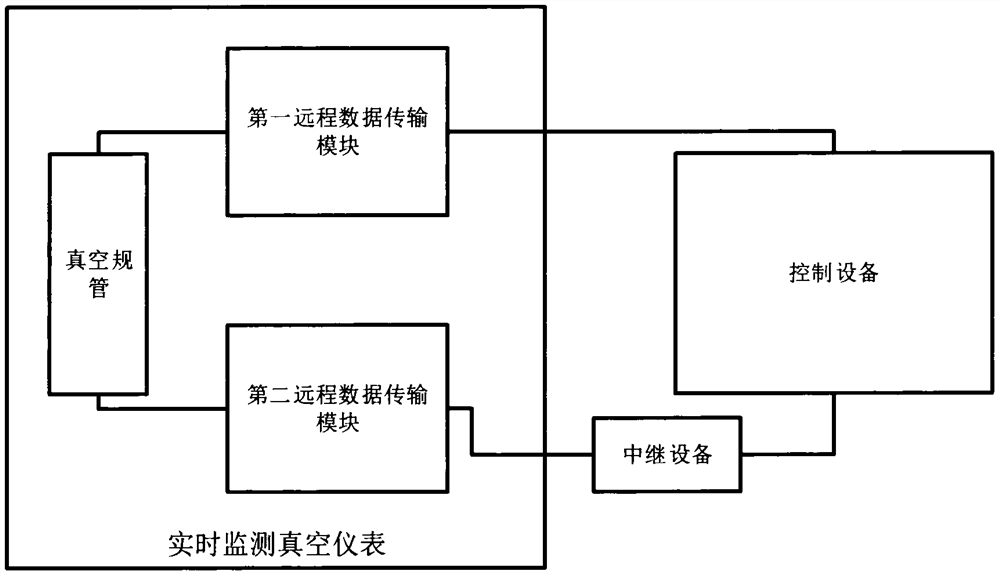

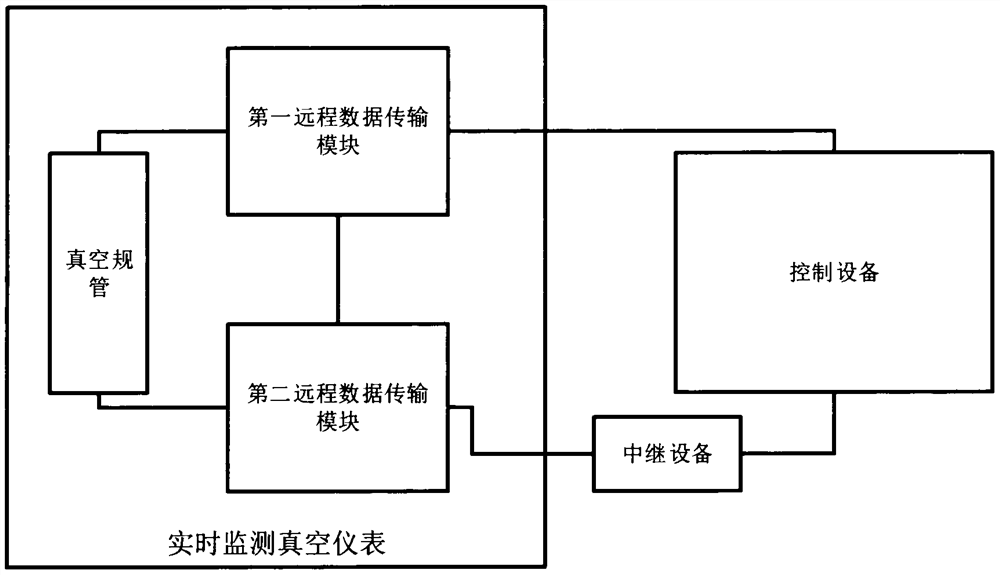

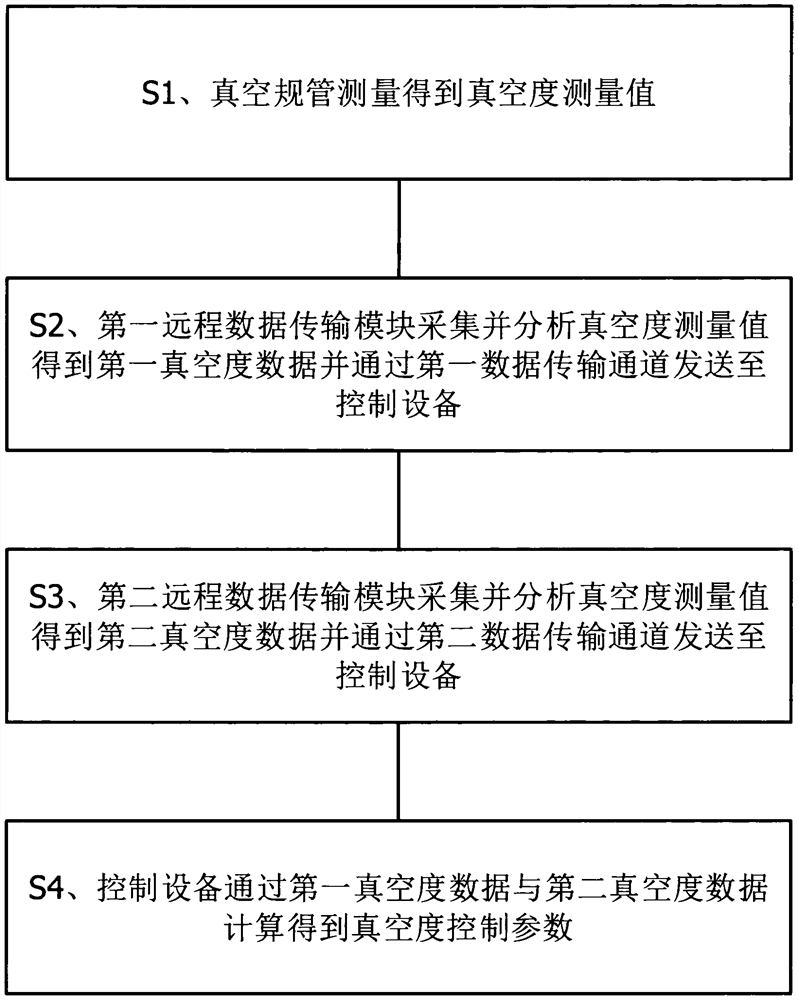

[0036] Such as figure 1 Shown is a schematic structural diagram of the first embodiment of the real-time monitoring vacuum instrument of the present invention, including a vacuum gauge and a first remote data transmission module and a second remote data transmission module respectively connected to the vacuum gauge. The first remote data transmission module and the second remote data transmission module respectively collect and analyze the vacuum measurement values measured by the vacuum gauge by connecting with the vacuum gauge to obtain the first vacuum degree data and the second vacuum degree data respectively. In order to realize mutual verification between different data and ensure the reliability of data transmission, the first remote data transmission module is a wireless network transmission module, and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com