Rubber composition

A rubber composition and rubber technology, applied in the direction of electrochemical generators, fuel cell parts, fuel cells, etc., can solve the problems of easy adhesion, weak green strength, raw material fracture, etc., and achieve excellent resistance to compression set Characteristics, effect of improving roll workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] For the preparation of the rubber composition, it can be obtained by mixing the above-mentioned various materials using a mixer such as a single-screw extruder, a twin-screw extruder, a roll, a Banbury mixer, a kneader, a high-shear type mixer, etc. Melting and kneading are carried out at a melting temperature of 120 to 150°C.

[0040] In addition, the crosslinking of the rubber composition can be carried out by using an injection molding machine, a compression molding machine, etc., usually by pressurized crosslinking at about 155 to 230° C. for about 0.5 to 30 minutes. In addition, after performing the above-mentioned primary crosslinking, in order to ensure crosslinking up to the inside of the crosslinked product, secondary crosslinking may be performed if necessary. The secondary crosslinking can be carried out by heating in an oven usually at about 150 to 250° C. for about 0.5 to 24 hours.

[0041] The rubber cross-linked molded product obtained by cross-linking a...

Embodiment 1

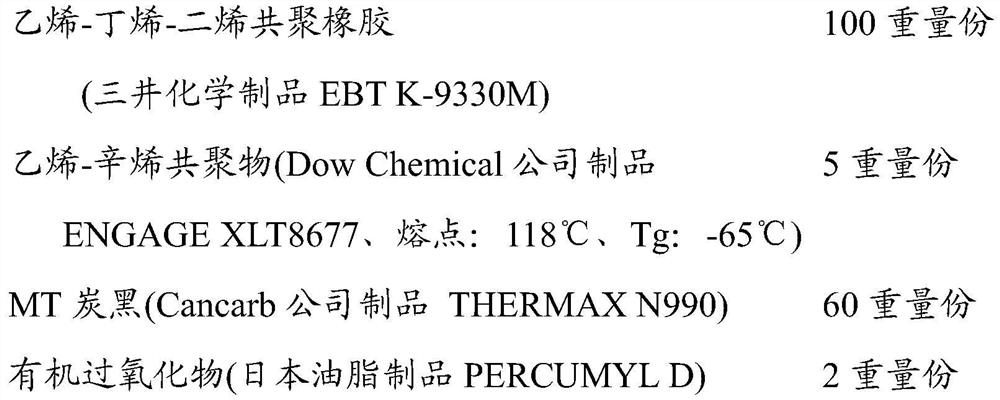

[0046]

[0047] Each of the above components except the organic peroxide was kneaded using a 120° C. kneader, and then the organic peroxide was added and kneaded using an open roll.

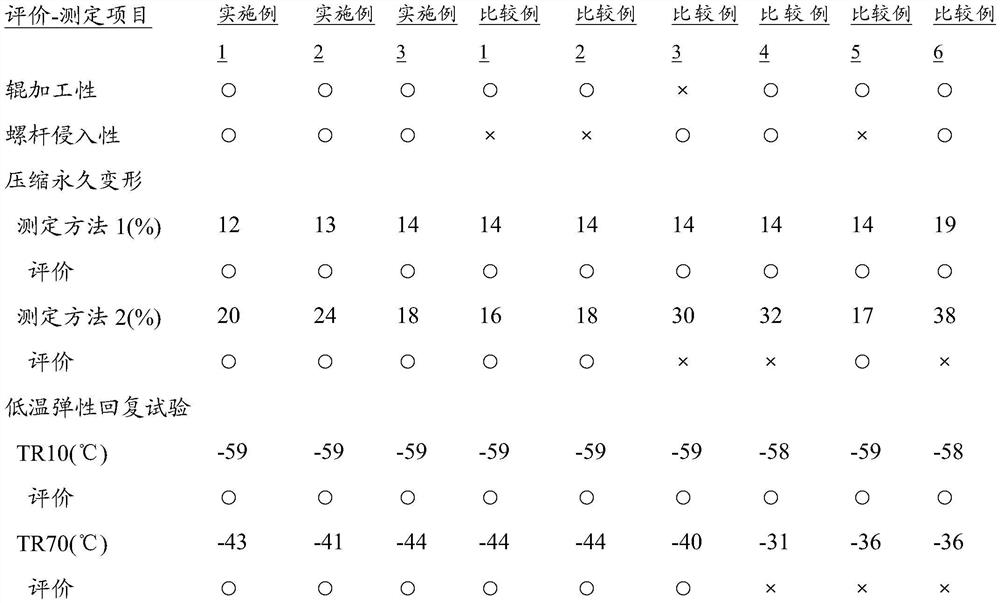

[0048] The kneaded product was crosslinked at 180° C. for 10 minutes, followed by oven crosslinking at 150° C. for 24 hours to obtain a crosslinked molded product. With regard to the kneaded product and the cross-linked molded product, the following items were evaluated and measured.

[0049] Roll processability:

[0050] ○Roll winding is good

[0051] ×Does not wrap around the roll

[0052] Intrusion of raw materials to the screw:

[0053] ○The intrusion of raw materials to the screw is good

[0054] ×The rubber material breaks due to the shearing of the screw

[0055] Compression set:

[0056] Laminate three sheets with a thickness of 2 mm, for 95 ° C in air, 500 hours, 25%

[0057] The compression set after compression was measured

[0058] Measurement method 1: JIS K6262 standard c...

Embodiment 2

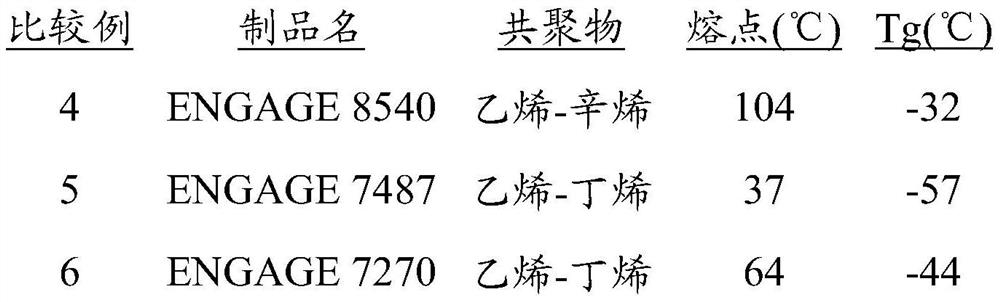

[0070] In Example 1, the amount of the ethylene-octene copolymer was changed to 7 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com