Composite light-storing ceramic for fire-fighting indication and preparation method thereof

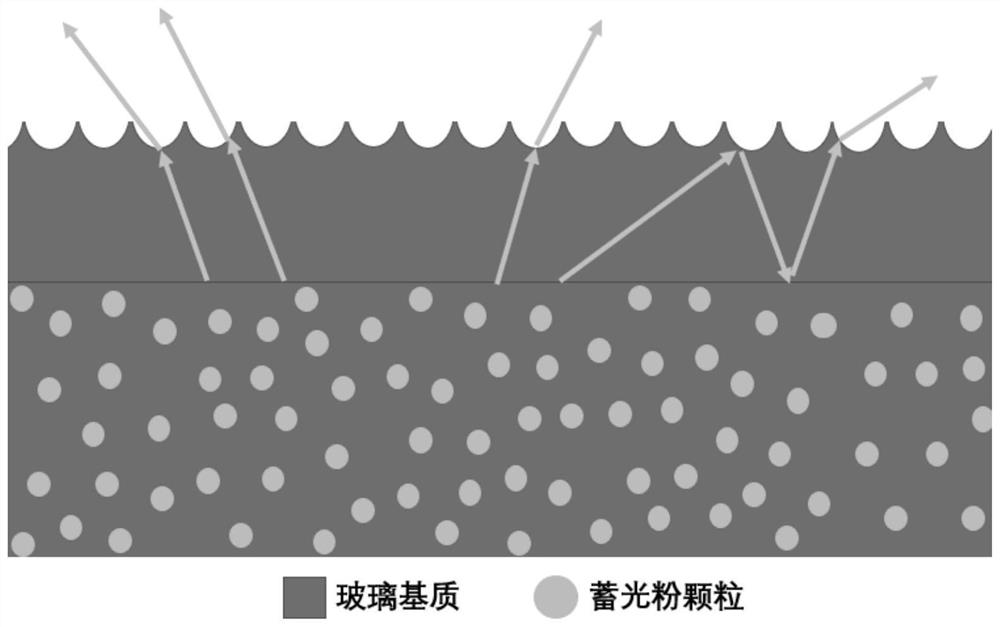

A ceramic and indicating technology, which is applied in the direction of glass manufacturing equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of unstable luminous efficiency and low yield rate of products, improve visual comfort, improve light efficiency, and increase gloss degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific process includes the following steps:

[0035] 1) Weighing of raw materials: respectively weigh light storage powder (CaAl 2 o 4 : Eu, Nd) 10 parts, particle size 80 mesh glass frit 90 parts.

[0036] 2) Powder configuration and processing: Put the weighed raw materials into the granulator and directly stir and granulate, and then get the mixture after stirring for 1 hour; the speed of the granulator during the whole stirring process is 80rad / min.

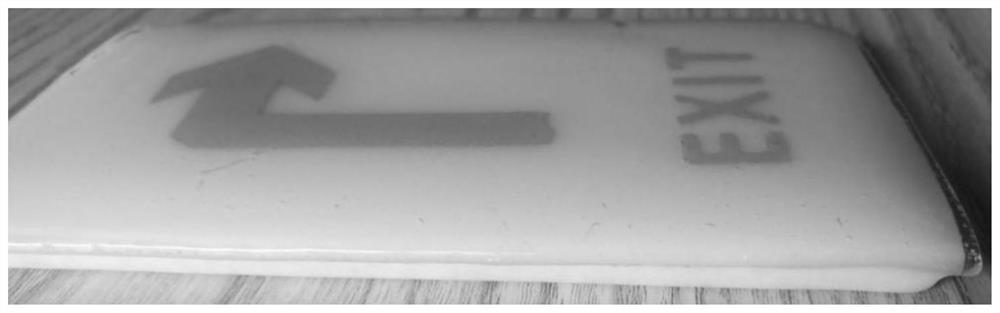

[0037] 3) Powder forming: the mixture obtained in step 2) is directly sieved and spread into the mold through the internal screen of the distributing machine (the aperture is 20 mesh), and then printed on the surface of the mixture by a screen printing machine. The frosted glass sheet with the exit instruction pattern (roughness 13 microns, thickness 3 mm), with the printed side facing down, the mold and the frosted glass sheet are both rectangular (10cm*20cm), and then sent to a roller kiln for firing.

[00...

Embodiment 2

[0042] The specific process includes the following steps:

[0043] 1) Weighing of raw materials: Weigh the light storage powder (Sr 4 Al 14 o 25 : Eu, Dy) 25 parts, particle size 100 mesh glass frit 75 parts.

[0044] 2) Powder configuration and processing: put the weighed raw materials into the granulator and directly stir and granulate, and then get the mixture after stirring for 2 hours; the speed of the granulator is 100rad / min during the whole stirring process.

[0045] 3) Powder stacking molding: the mixture obtained in step 2) is directly sieved into the mold through the internal screen of the distributing machine (aperture 40 mesh), and printed on the surface of the mixture by a screen printing machine. The frosted glass sheet with the exit instruction pattern (roughness 10 microns, thickness 2 mm), the printed side facing down, the mold and the frosted glass sheet are both square (25cm*25cm), and then sent to the roller kiln for firing.

[0046] 4) Firing: Preheat...

Embodiment 3

[0050] The specific process includes the following steps:

[0051] 1) Weighing of raw materials: Weigh the light storage powder (SrAl 2 o 4 : Eu, Dy) 30 parts, particle size 200 mesh glass frit 70 parts.

[0052] 2) Powder configuration and processing: Put the weighed raw materials into the granulator and directly stir and granulate, and then get the mixture after stirring for 3 hours; the speed of the granulator during the whole stirring process is 250rad / min.

[0053] 3) Powder stacking molding: the mixture obtained in step 2) is directly sieved into the mold through the internal screen of the distributing machine (the aperture is 60 mesh), and then the emergency exit is printed on the surface of the mixture through a screen printing machine The frosted glass sheet indicating the pattern (roughness is 7 microns, thickness is 0.5 mm), the printed side is facing down, the mold and the frosted glass sheet are both square (25cm*25cm), and then sent to the roller kiln for firin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com