Delustering and paper removing additive for heat transfer printing powder coating

A powder coating and additive technology, applied in powder coatings, coatings, etc., can solve the problems of poor paper removal and high cost of polyurethane polyester powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

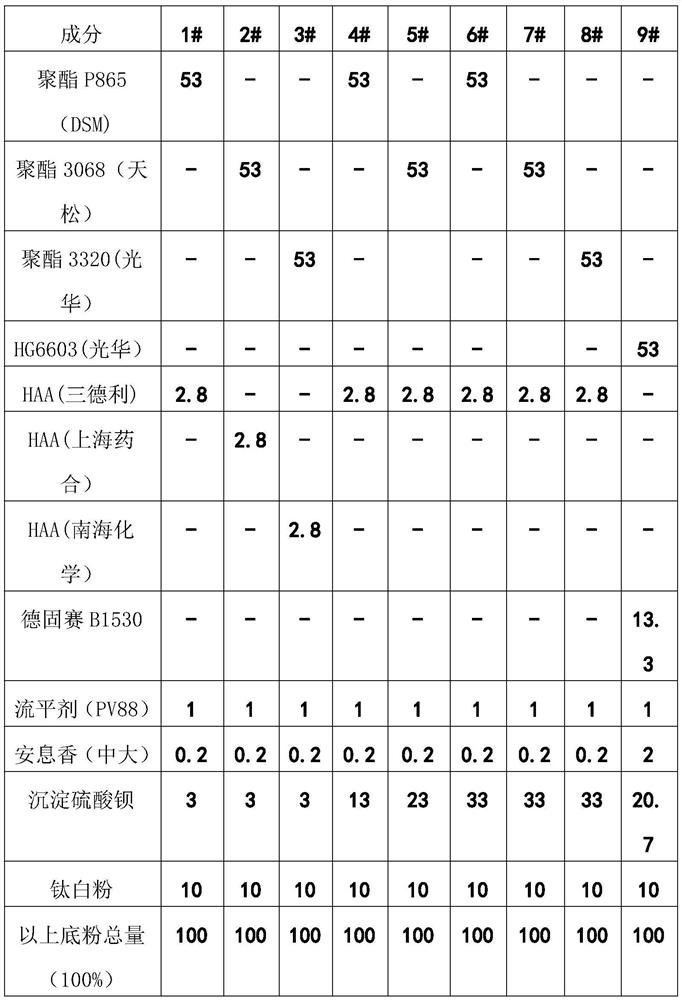

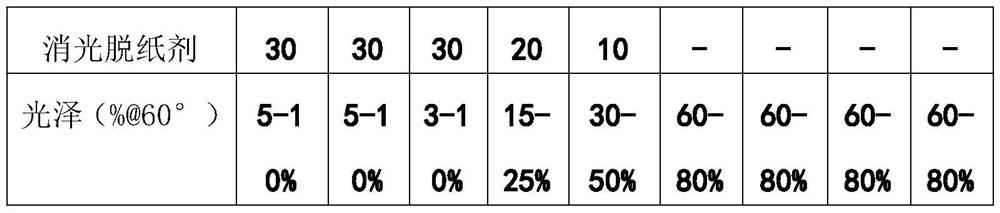

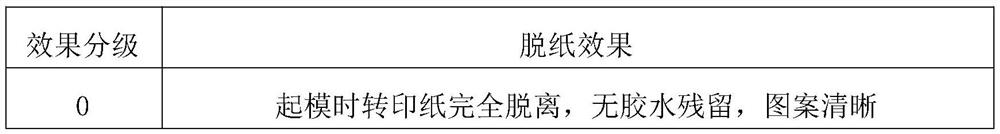

Method used

Image

Examples

Embodiment 1

[0024] A delustering and paper-removing additive for thermal transfer powder coatings, which consists of the following components by weight percentage: GMA160 10-50%, A65 5-30%, A320 20-40%, DDDA 5-10%, M-11 2 to 8%, the sum of the weight percentages of each component is 100%.

Embodiment 2

[0026] A delustering and paper-removing additive for thermal transfer powder coatings, which consists of the following components by weight percentage: GMA400 10-70%, A130 5-50%, A200 5-60%, A320 10-60, DDDA 5-30 %, M-17 2 to 8%, the sum of the weight percentages of each component is 100%.

Embodiment 3

[0028] A delustering and paper-removing additive for thermal transfer powder coating, which is composed of the following components by weight percentage: GMA160 5-50%, GMA550 10-50%, A65 10-70%, DDDA 5-20%. The sum of weight percentages is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com