Pure cotton four-sided elastic easy-care finish fabric, as well as production method and application thereof

A production method and technology of four-way stretch, which is applied in the field of textile dyeing and finishing, can solve problems affecting the quality of four-way stretch fabrics, low product quality, foaming and wrinkling, etc., achieve the advantages of non-ironing appearance and hand feeling, short processing process, and low processing cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

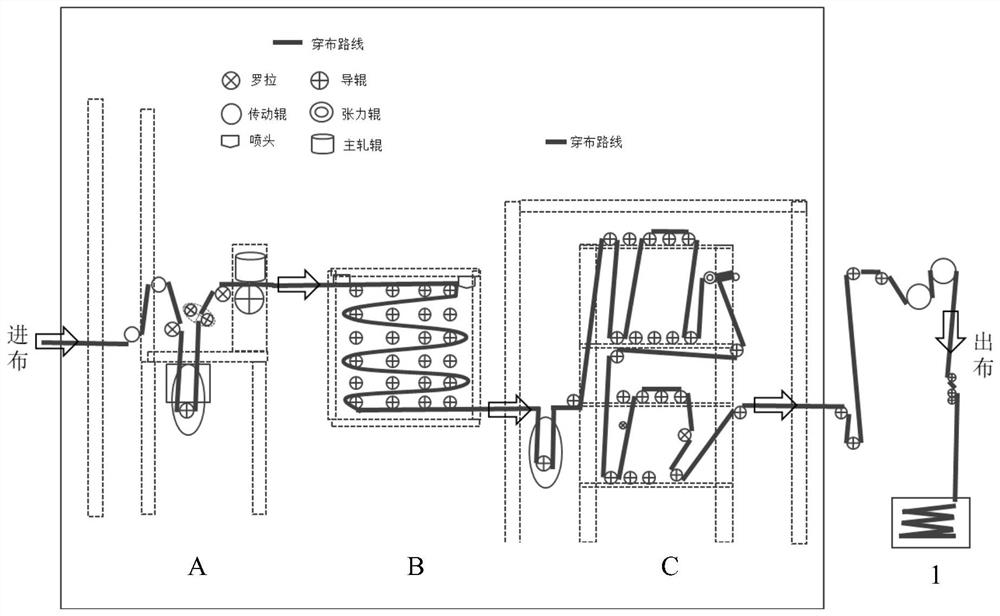

[0049] This embodiment provides a combination equipment for loose-type mercerized liquid ammonia finishing, and its structural schematic diagram is as follows figure 1 shown, from figure 1 It can be seen from the figure that the combined equipment for loose-type mercerizing liquid ammonia finishing includes: loose-type mercerizing finishing area A, Z-type stacking area B and loose-type liquid ammonia finishing area C;

[0050] The desized fabric enters the loose mercerizing finishing area A through the cloth inlet, and the fabric is impregnated with lye under the action of the driving roller and rollers. Specifically, the driving roller has a transmission function and can transfer the fabric from the cloth inlet to the loose mercerizing area A. Type mercerizing finishing area; the roller has the function of expanding, and can pull the cloth width before and after soaking in lye, so that the fabric is in a state of open width in the loose type mercerizing finishing area, and av...

Embodiment 2

[0054] This embodiment provides a method for making a soft and smooth pure cotton four-way stretch non-ironing fabric, wherein the method includes the following steps:

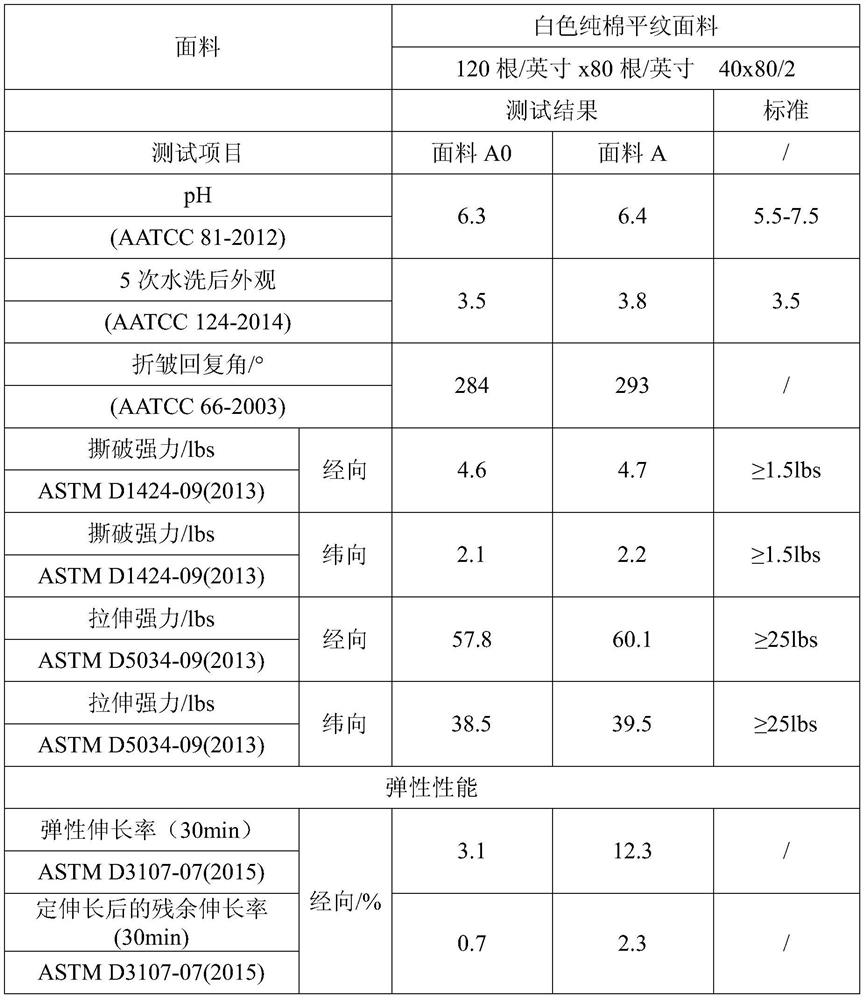

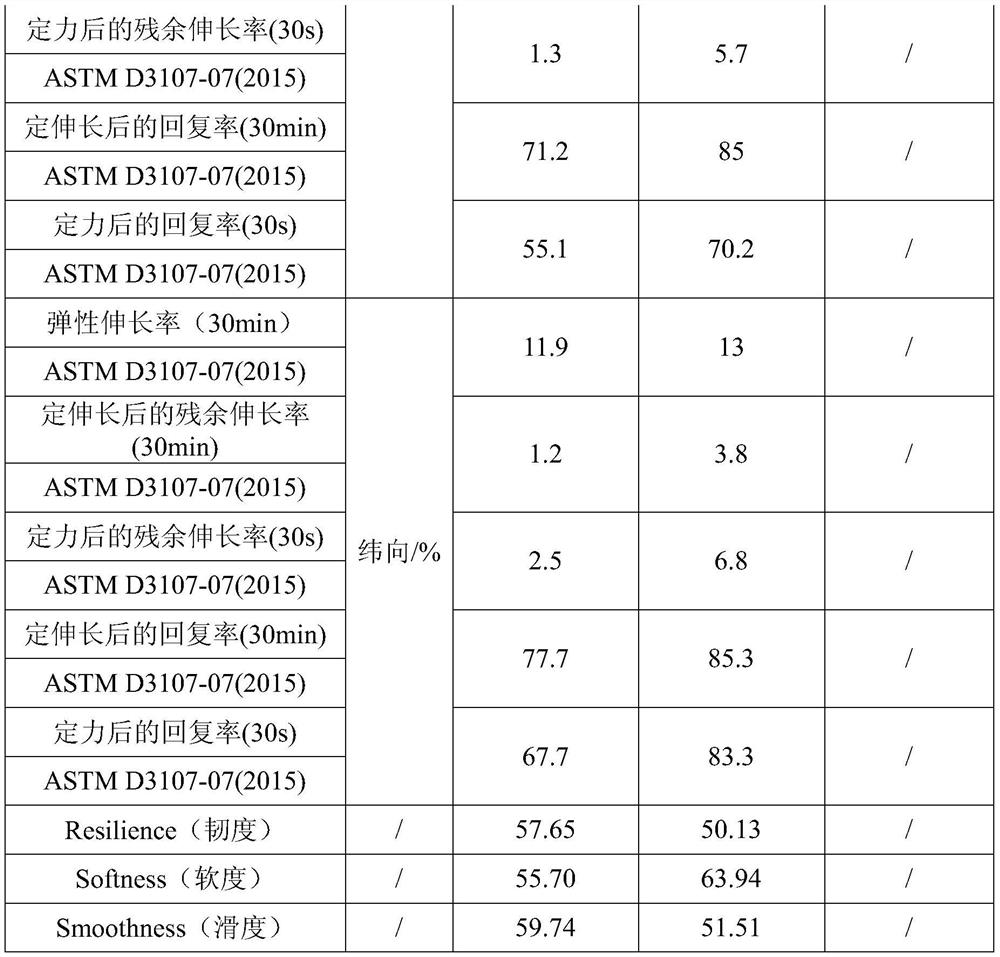

[0055] Singeing and desizing are carried out successively to white plain cloth (the specification is pure cotton 40s * pure cotton 80s / 2, warp density * weft density is 120 * 80 pieces / inch), and the fabric after desizing is provided in embodiment 1 The loose-type mercerizing area of the loose-type mercerizing liquid ammonia finishing combined equipment is used for loose-type mercerizing. The concentration of mercerizing alkali used in loose-type mercerizing is 200g / L, and the alkali-carrying rate of the fabric after loose-type mercerizing is 80%;

[0056] The fabric after loose mercerizing is stacked in the Z-shaped stacking area of the loose-type mercerizing liquid ammonia finishing combined equipment for 3 hours. The lye dripped during the stacking process is sprayed on the fabric again, so that the alk...

Embodiment 3

[0060] This embodiment provides a method for making a soft and smooth pure cotton four-way stretch non-ironing fabric, wherein the method includes the following steps:

[0061] Singeing and desizing are carried out successively to the white Oxford fabric (the specification is pure cotton 40s × pure cotton 80s / 2, and the warp density × weft density is 160 × 70 threads / inch), and the fabric after desizing is placed in Example 1 The loose-type mercerizing area of the provided loose-type mercerizing liquid ammonia finishing combined equipment is used for loose-type mercerizing. The concentration of mercerizing alkali used in loose-type mercerizing is 300g / L, and the alkali-carrying rate of the fabric after loose-type mercerizing is 110%;

[0062] The fabric after loose mercerizing is stacked in the Z-shaped stacking area of the loose-type mercerizing liquid ammonia finishing combined equipment for 4 hours. The lye dripped during the stacking process is sprayed on the fabric ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com