Trench type prefabricated assembly type cable duct bank and working well installation construction method

A technology of cable pipe arrangement and prefabricated assembly, which is applied in cable installation, ground cable installation, and cable installation in underground pipelines, etc. It can solve the problems of inability to enter the site for large construction equipment, poor flexibility of prefabricated components, structural integrity and sealing Poor performance and other problems, to achieve the effect of quick assembly, reduced rental time, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

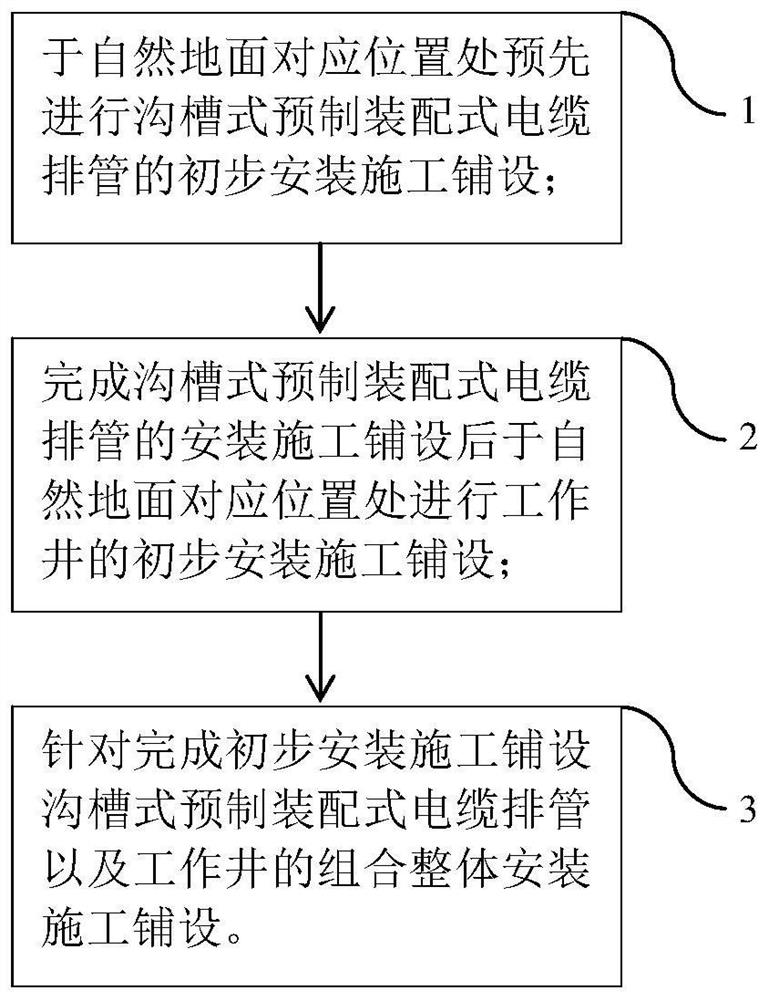

[0062] Such as figure 1 Shown is the method flowchart of the present invention, and this method specifically comprises:

[0063] Step 1: Preliminary installation, construction and laying of the grooved prefabricated cable conduit at the corresponding position on the natural ground;

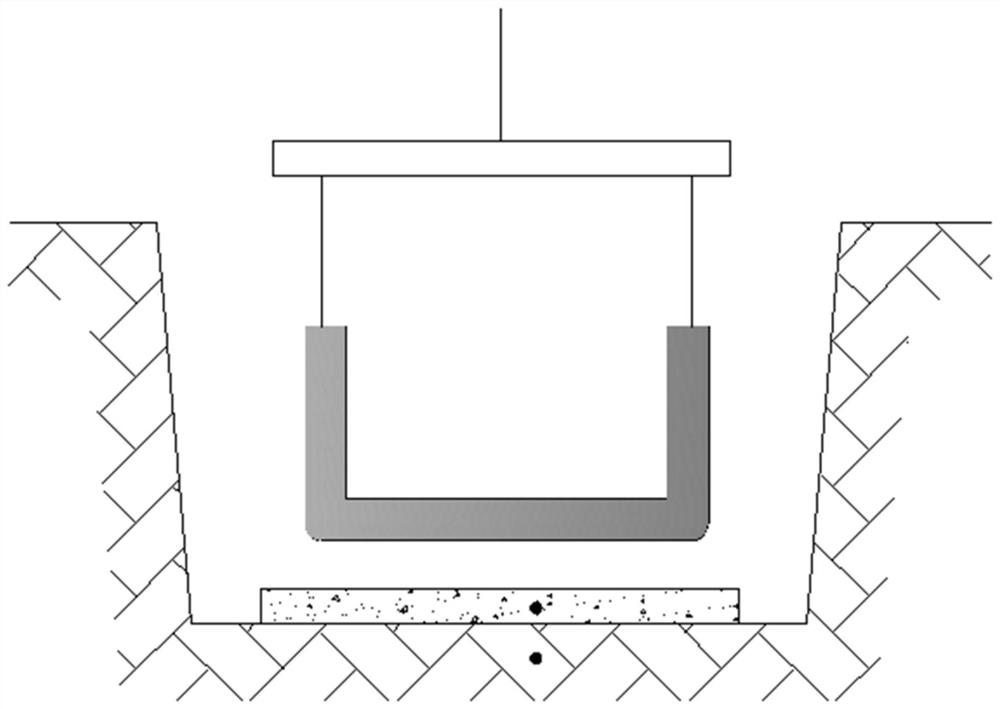

[0064] Step 2: After completing the installation, construction and laying of the grooved prefabricated cable conduit, carry out the preliminary installation, construction and laying of the working well at the corresponding position on the natural ground;

[0065] Step 3: For the completion of preliminary installation and construction, the overall installation and construction of the combination of trenched prefabricated cable pipes and working wells is laid.

[0066] Among them, step 1 specifically includes:

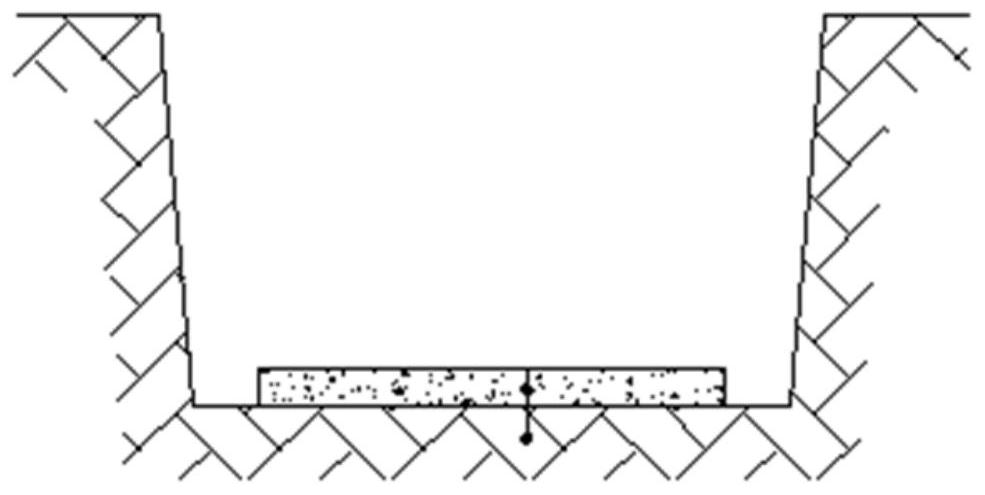

[0067] (1) Foundation trench excavation. The excavation adopts human-machine mixing, and the excavator digs the groove to ensure that the soil structure at the bottom of the groove is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com