A flexible wearable sensor array and its preparation method

A sensor array, flexible technology, applied in the direction of nanotechnology for sensing, measurement of the property force of piezoelectric resistance materials, nanotechnology, etc., can solve the problem of small number of detection and recording signals, low sensitivity of wearable sensors, Single function, etc., to achieve excellent tensile properties, simple and efficient preparation process, and low relaxation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

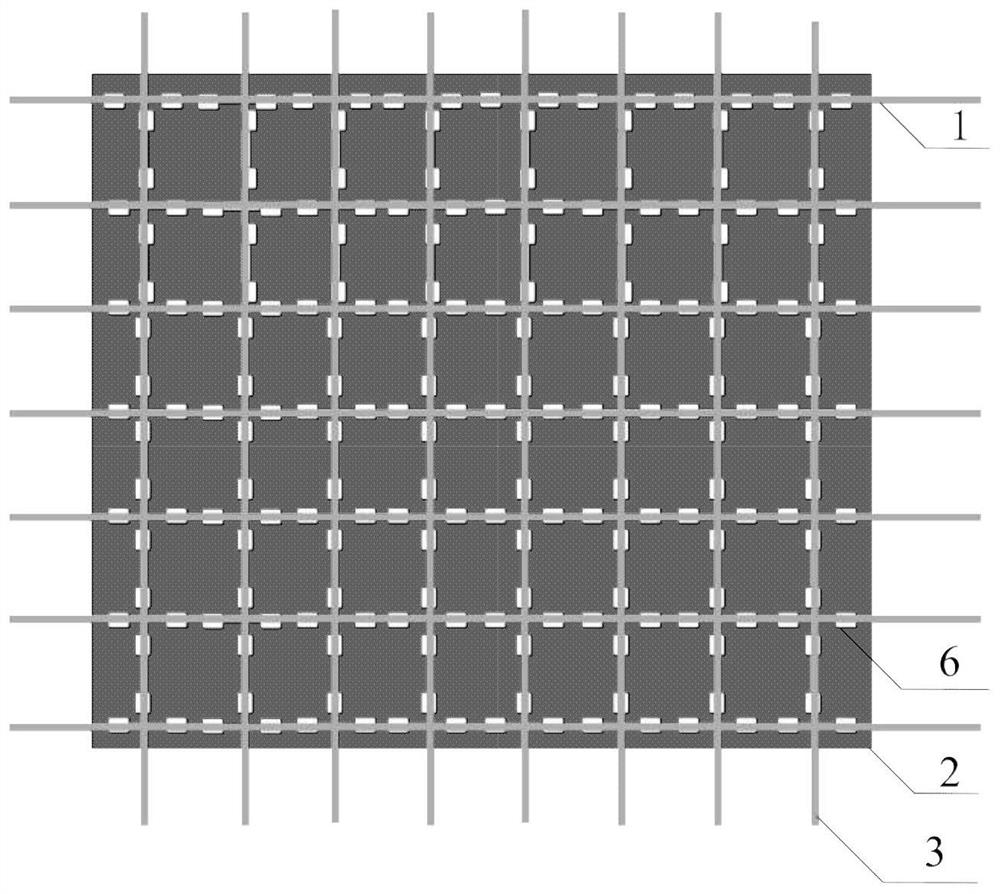

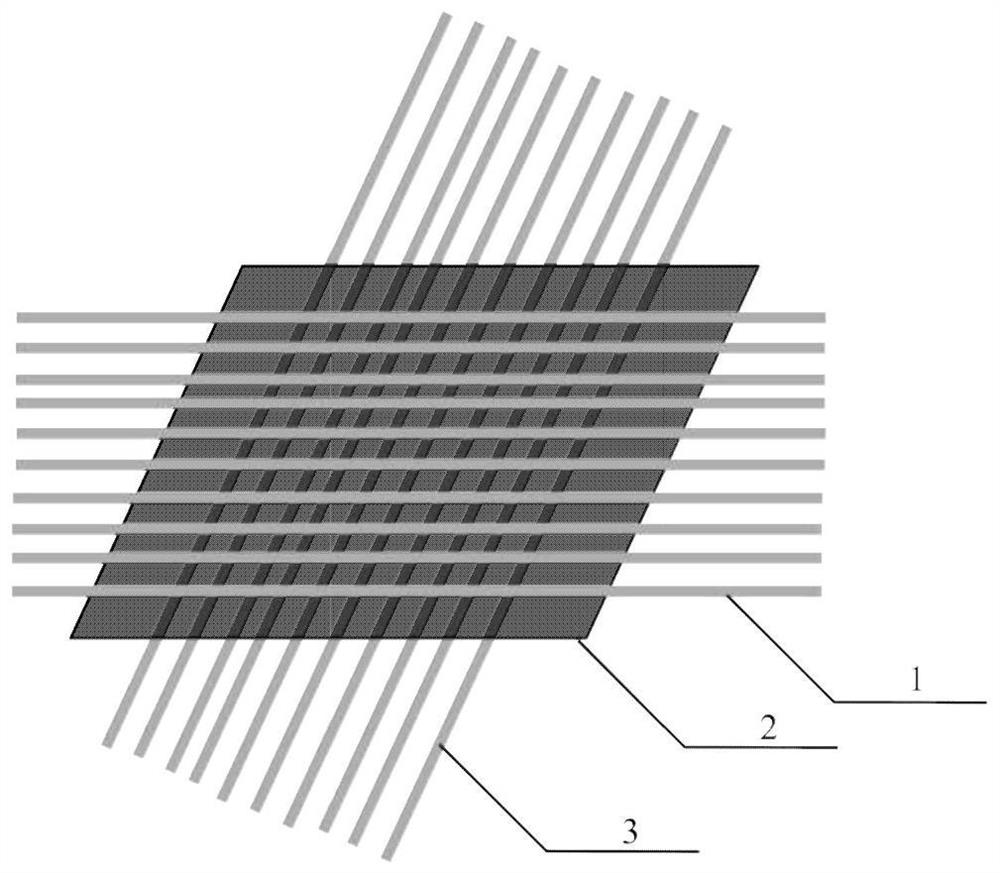

[0048] A high-sensitivity flexible wearable sensor array and its preparation method. In this embodiment, force-sensitive films, orthogonal wires, tapes, and insulating films are laminated into a sensor array; through overlapping between 10 rows and 10 columns of electrodes, Area-sensing force-sensitive thin film resistance changes in response to force, and then a high-sensitivity flexible wearable sensor array is obtained.

[0049] The specific preparation of the technical solution of this embodiment is realized through the following processes:

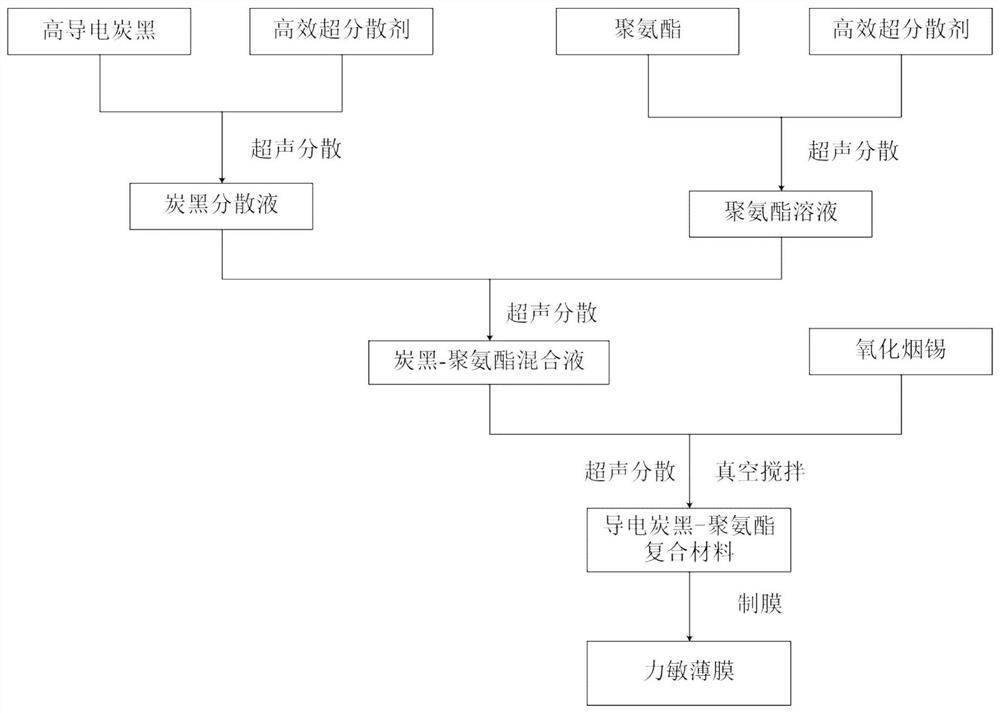

[0050] (1) Preparation of force sensitive film

[0051] 1) Preparation of carbon black dispersion: use an ultrasonic disperser to ultrasonically disperse carbon black and dispersant for 30-60 minutes to obtain a uniform carbon black dispersion for later use;

[0052] 2) Polyurethane solution preparation: use an ultrasonic disperser to ultrasonically disperse the polyurethane and dispersant for 30-60 minutes to obtain a uniform polyur...

Embodiment 2

[0074] In this embodiment, the mass fraction of carbon black in the conductive film is 6wt.%; the thickness of the force-sensitive film is 0.2 mm; the insulating film is a polyimide film with a thickness of 30 μm; the row conductors and the column conductors are respectively 10, It can be seen that a 10×10 sensor array has been prepared, which can be integrated on the insole to sense the tactile information of the sole of the human body during exercise.

Embodiment 3

[0076] In this embodiment, the mass fraction of carbon black in the conductive film is 7wt.%; the thickness of the force-sensitive film is 0.1 mm; the insulating film is a polytetrafluoroethylene film with a thickness of 10 μm; the number of row conductors and column conductors is 64, respectively. A 64×64 sensor array is prepared, which can be integrated into the upper-use glove to realize tactile perception when the hand completes the grasping action.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com