Unit sliding pressure control optimization method and system based on thermoelectric load condition

An optimization method and electric load technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as unusable, reduced unit economy, and unsuitable heat and power cogeneration units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

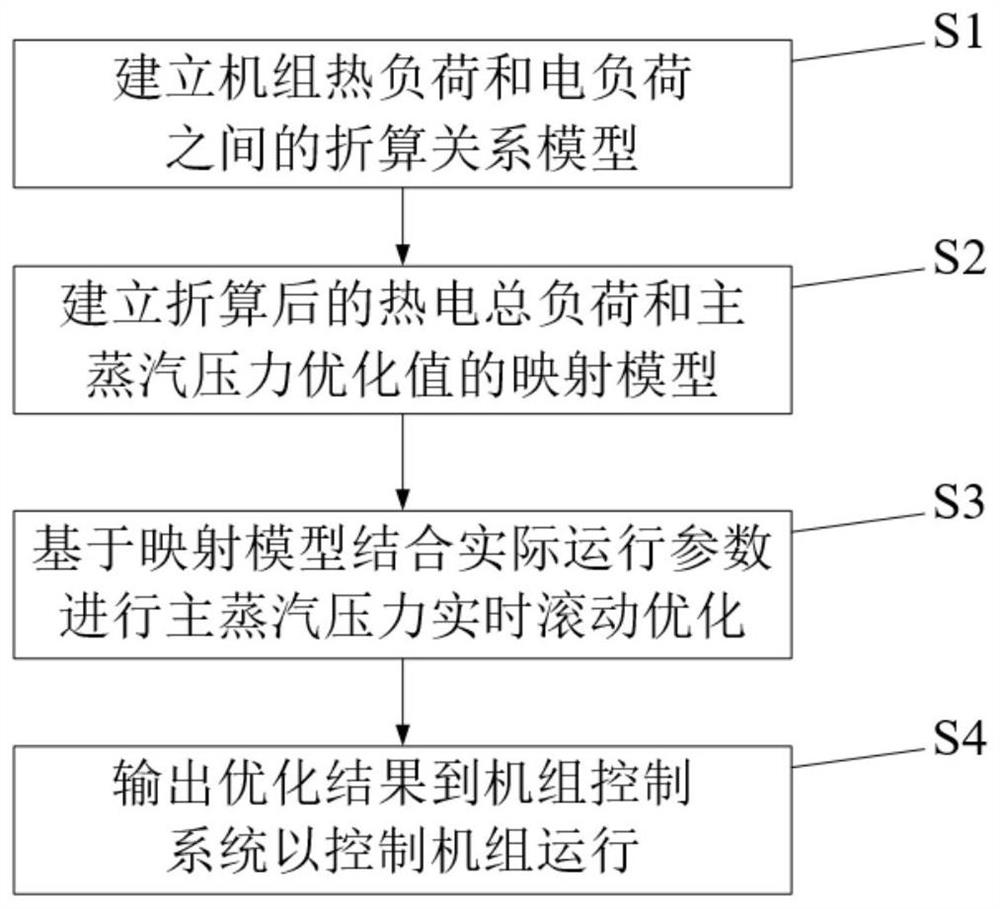

[0114] A real-time optimization method for unit sliding pressure control strategy based on thermal and electrical load conditions, taking a 300MW cogeneration unit in a power plant as an example, includes the following steps:

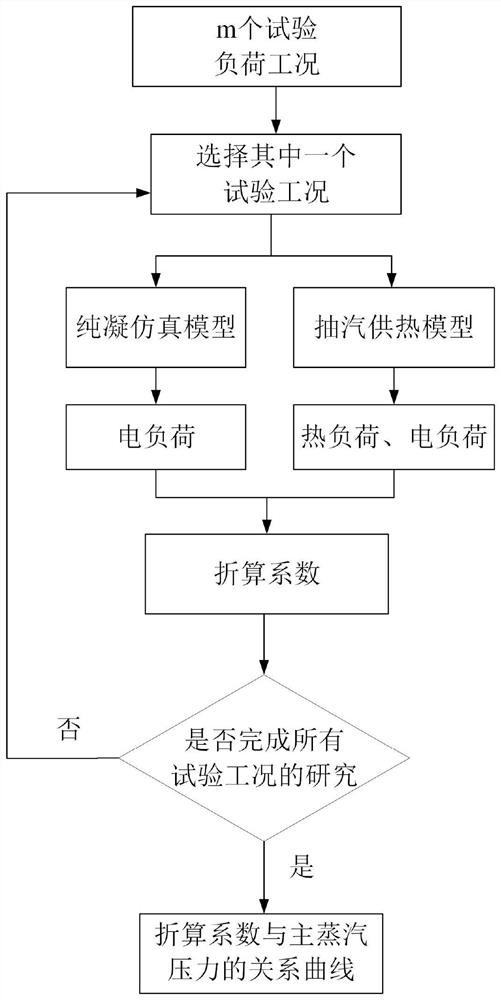

[0115] Step S1, as attached image 3 As shown in the flow chart, the conversion relationship model of unit thermal load converted into electrical load under different loads is established.

[0116] S11, from the effective operating load range of the steam turbine (30%-100%), select a load every 5%, and select the working conditions of 30%, 35%, 40%, ..., 95%, 100% load as the test Load, the corresponding electric load is 90MW, 105MW, ..., 300MW.

[0117] S12, take the test condition of a load in S11, denoted as condition 0, and use the heat balance simulation software of the thermal system to establish a simulation model of the pure condensing power generation condition under this load.

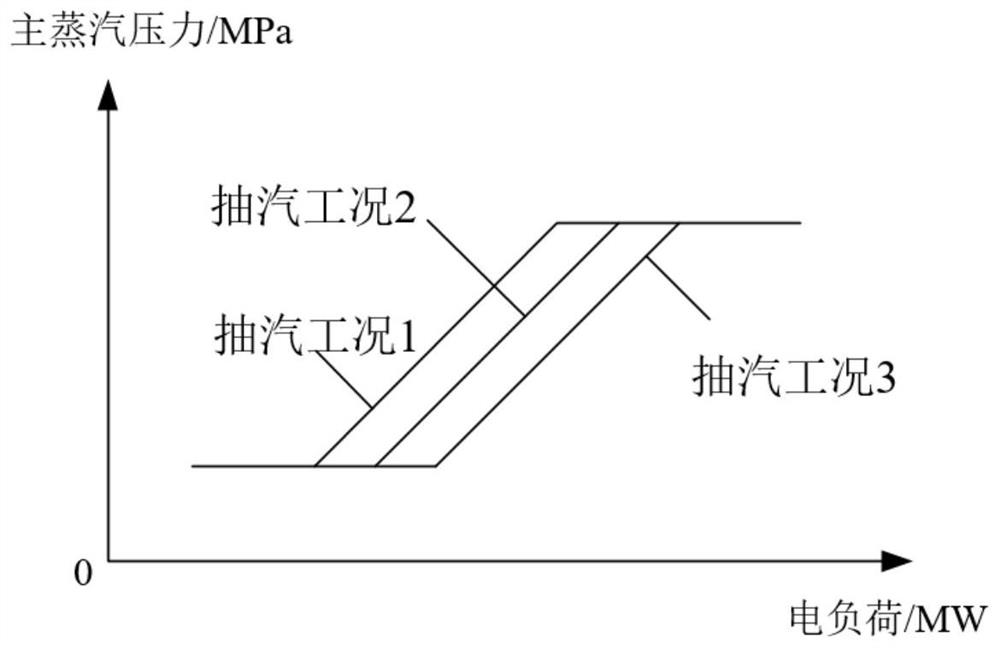

[0118] S13, the 300MW unit shown in this embodiment has three s...

Embodiment 2

[0160] On the basis of the above-mentioned embodiment 1, this embodiment also provides a system for optimizing the sliding pressure control of the unit based on thermal and electrical load conditions, including:

[0161] The input module is used to obtain the real-time operation data of the cogeneration unit;

[0162] The constraint module is used to limit the range of independent variables of the algorithm in the optimization module and improve the efficiency of optimization according to the characteristics of the heating network and power grid dispatching, as well as the heat balance relationship during the operation of the unit. The constraint module includes: real-time The main steam pressure range constraint module of main steam parameters, the thermoelectric load range constraint module based on the dispatching characteristics of the heating network and power grid, and the range constraint module of other independent variables based on mass conservation and heat balance r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com