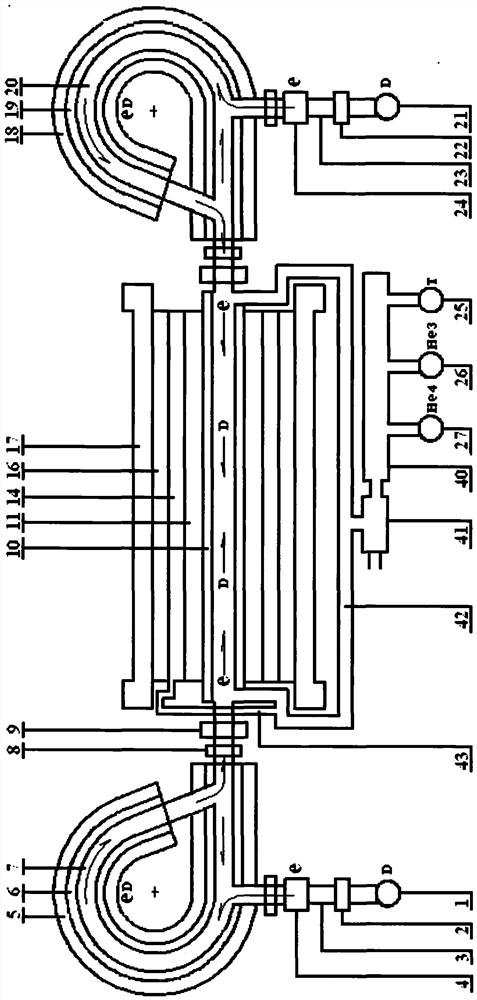

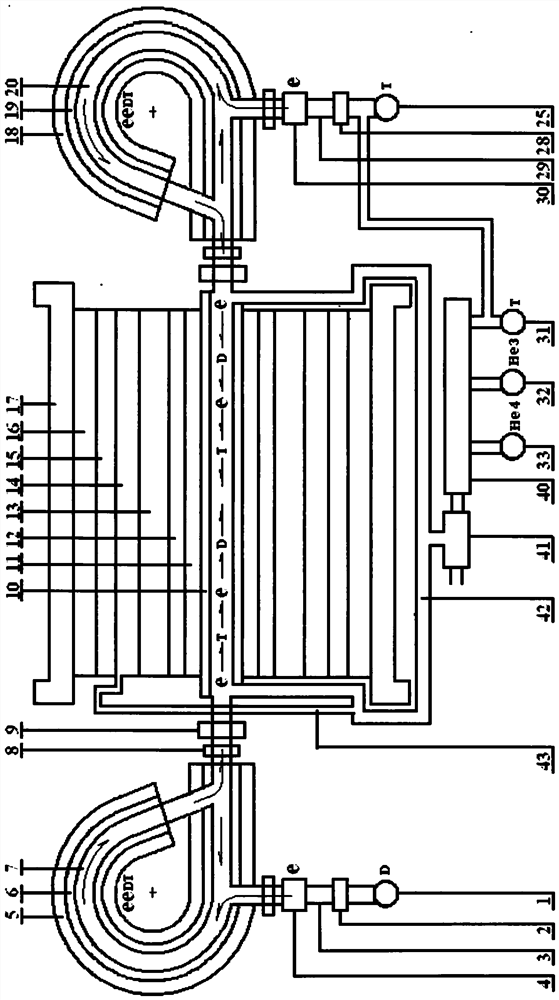

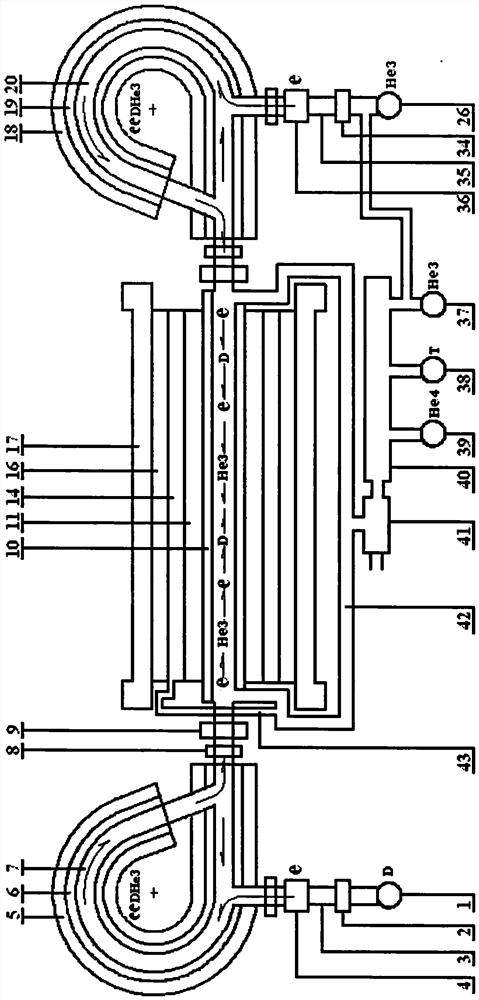

Magnetic-confinement annular return pipe and straight fusion pipe

A return tube, magnetic confinement technology, used in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The high-purity deuterium gas, heavy water, lithium 6, superconducting coils, vacuum pumps, stainless steel tubes, gas cylinders, etc. required by this project have mature products. Megawatt-level deuterium-tritium fusion tube devices, tungsten fusion tubes, annular return tubes, multilayer tungsten tubes for breeding neutrons, ion sources and ion accelerator tubes, electromagnetic gas separators, etc., will become a subsidiary of Nuclear Fusion Group Corporation research institutes and companies to develop. This project requires an investment of tens of millions of yuan to start the development of a megawatt-level deuterium-tritium fusion tube experimental device to provide reliable technical support for product research and development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com