Alkali liquor oxidation regeneration tail gas cleaning treatment and reutilization method and system

A technology for cleaning exhaust gas and lye, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., to avoid the problem of furnace flue gas emission, reduce factory air volume, and save stainless steel pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] According to a preferred embodiment of the present invention, a method for cleaning and reusing alkali liquor oxidation regeneration tail gas, the method comprises the following steps:

[0047] ① The tail gas from the alkaline oxidation regeneration tower passes through the adsorption tank A equipped with adsorbent from bottom to top to remove the N 2 、H 2 O and hydrocarbons to obtain oxygen enriched gas;

[0048] ② After the oxygen-enriched gas is settled and separated from the liquid by the oxygen-enriched gas liquid separation tank, it is boosted by the booster and sent to the gas cooler for cooling;

[0049] ③The cooled oxygen enriched gas is mixed with the external factory air in the mixer to obtain the mixed gas;

[0050] 4. the mixed gas returns to the air inlet of the lower part of the lye oxidation regeneration tower through the online analyzer;

[0051] ⑤ When the adsorption of the adsorbent in the adsorption tank A reaches saturation, switch the tail gas o...

Embodiment

[0072] This embodiment is used to illustrate the method and system of the present invention for cleaning, treating and reusing tail gas from oxidation and regeneration of alkali solution.

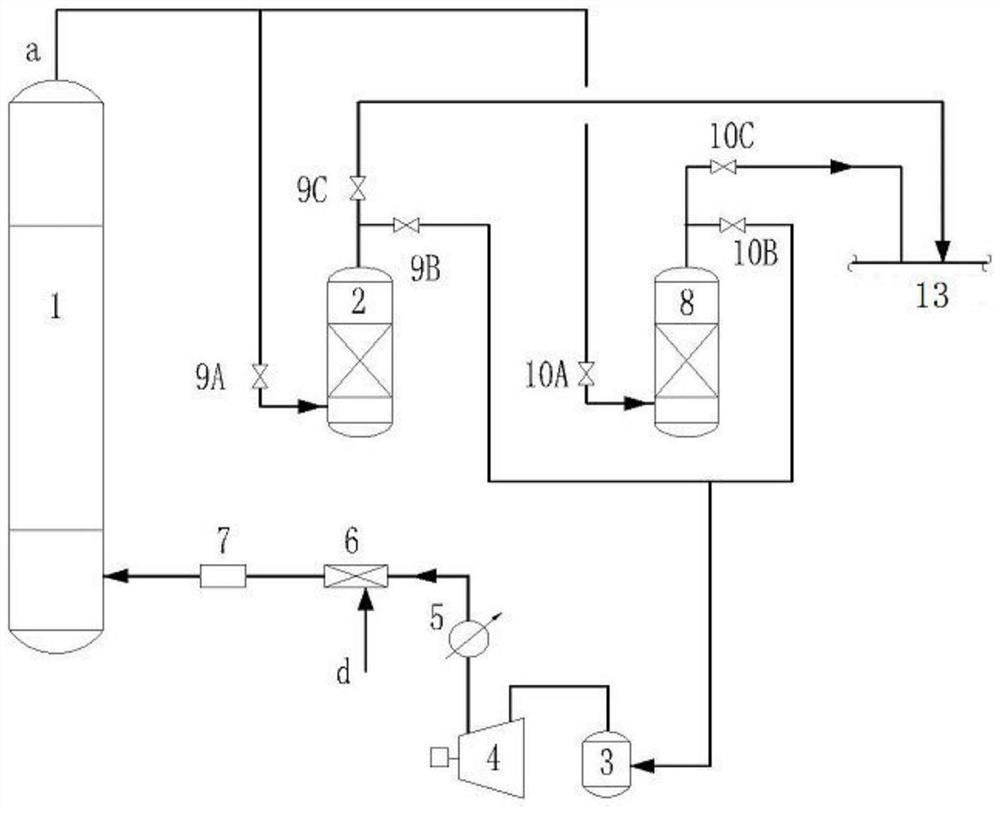

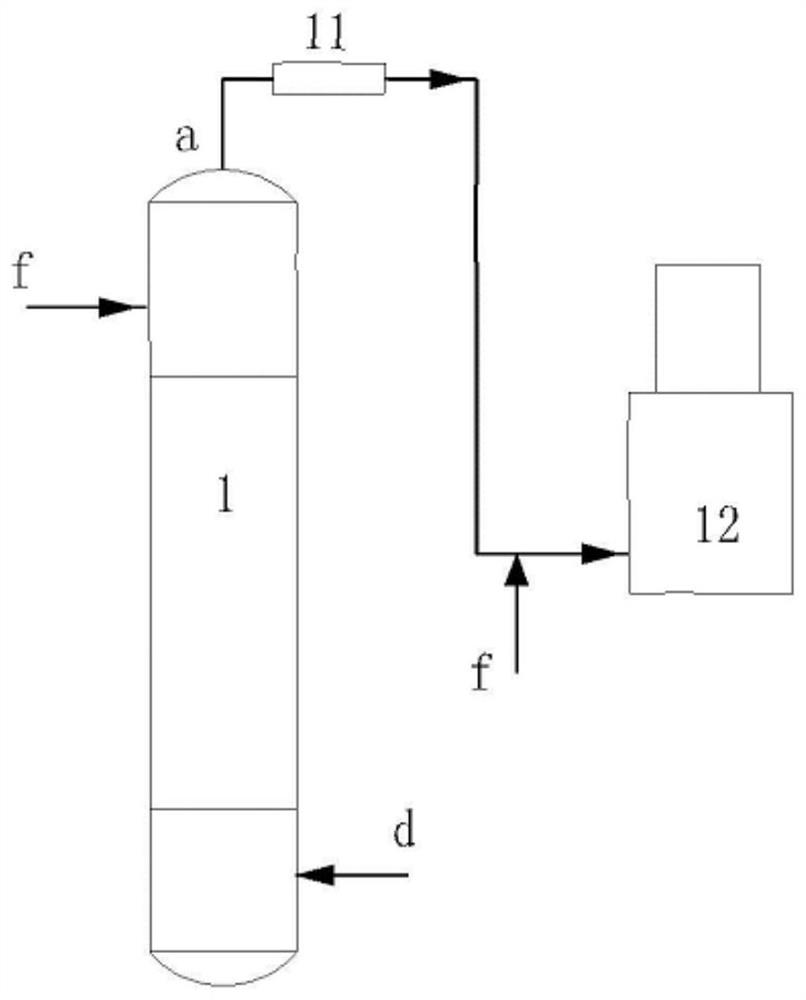

[0073] Such as figure 1 As shown, the present invention provides a kind of lye oxidation regeneration tail gas cleaning treatment and reutilization system, and this system comprises lye oxidation regeneration tower 1, adsorption tank A 2, adsorption tank B 8, oxygen enrichment gas separation tank 3, Turbocharger 4, gas cooler 5, mixer 6 and online analyzer 7;

[0074] The gas outlet of the lye oxidation regeneration tower 1 is communicated with the gas inlet of the adsorption tank A2 and the adsorption tank B8 respectively, and the gas outlet of the alkali lye oxidation regeneration tower 1 is connected with the gas inlet of the adsorption tank A2. The first switching valve α9A, the gas outlet of the lye oxidation regeneration tower 1 and the connecting pipeline of the gas inlet of the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com