Direct flotation regulator for collophanite containing high-power semi-oxide, and method and application thereof

A positive flotation and adjusting agent technology, applied in flotation, solid separation and other directions, can solve the problems of poor chemical selectivity, large loss, and large influence of ore sludge, and achieve the effect of firm adsorption and enhanced flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

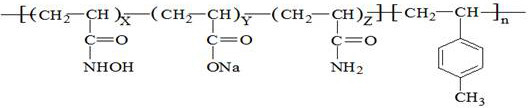

[0018] Embodiment 1, a kind of positive flotation adjustment agent that is used to contain high sesquioxide colloides, main component is polyacrylamide-p-methylstyrene hydroxamic acid sodium, and its structural formula is:

[0019]

[0020] In the formula: 87X+94Y+71Z+120n=1.6×10 6 ; X, Y, Z and n are all positive integers.

[0021] When it is used for the positive flotation of high-sesquioxide-containing collophosphine, the positive flotation desiliconization process is adopted, the grinding fineness is -0.074mm, and the particle size is 90%; the pH during the positive flotation process is 9.5 , the dosage of regulator sodium carbonate is 3.0kg / t, the dosage of regulator polyacrylamide-p-methylstyrene hydroxamic acid sodium is 50g / t; the dosage of inhibitor water glass is 2.5kg / t; the collector C18 unsaturated fatty acid saponification The material consumption is 1.0kg / t. After pulping, it enters the positive flotation tank for positive flotation desiliconization operati...

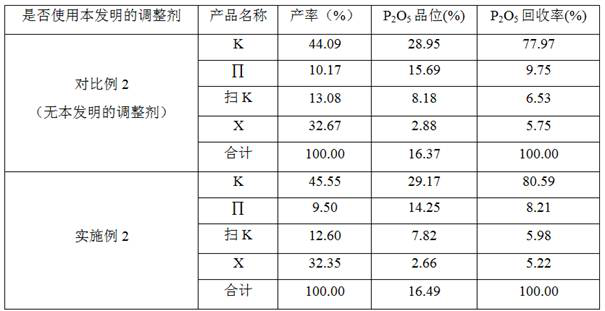

Embodiment 2

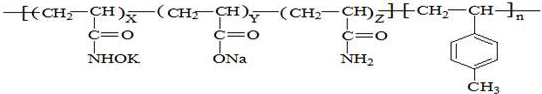

[0023] Embodiment 2, a kind of positive flotation adjustment agent that is used to contain high sesquioxide colloides, main component is polyacrylamide-p-methylstyrene base hydroxamic acid potassium, and its structural formula is:

[0024]

[0025] Where: 87X+94Y+71Z+120n=1.8×10 6 ; X, Y, Z and n are all positive integers.

[0026] (2) The method of use is as follows: the flotation adopts the positive flotation desiliconization process, the grinding fineness is -0.074mm and the particle size is 95%; the pH is 10 during the positive flotation process, and the dosage of the regulator sodium carbonate is 2.0kg / t , the dosage of regulator polyacrylamide-sodium p-methylstyrene hydroxamate is 60g / t; the dosage of inhibitor water glass is 4.0kg / t; the dosage of collector C18 unsaturated fatty acid saponification is 1.3kg / t. After pulping, it enters the positive flotation tank for positive flotation desiliconization operation, the foam product is concentrate, and the product in th...

Embodiment 3

[0028] Embodiment 3, a kind of positive flotation adjustment agent that is used to contain high sesquioxide collophanite, it is a kind of modified macromolecular compound, main component is polyacrylamide-p-methylstyrene base hydroxamic acid potassium , whose structural formula is:

[0029] Where: 87X+94Y+71Z+120n=1.7×10 6 ; X, Y, Z and n are all positive integers.

[0030] (2) The method of use is: the flotation adopts the positive flotation desiliconization process, the grinding fineness is -0.074mm, and the particle size is 80%; the pH is 10 during the positive flotation process, and the dosage of the regulator sodium carbonate is 3.0kg / t , the dosage of regulator polyacrylamide-sodium p-methylstyrene hydroxamate is 50g / t; the dosage of inhibitor water glass is 2.0kg / t; the dosage of collector C18 unsaturated fatty acid saponification is 1.2kg / t. After pulping, it enters the positive flotation tank for positive flotation desiliconization operation, the foam product is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com