Method and device for preparing periodic stripe structure on surface of glass coated with ITO (Indium Tin Oxide) film

A glass surface and stripe technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effect of convenient operation and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

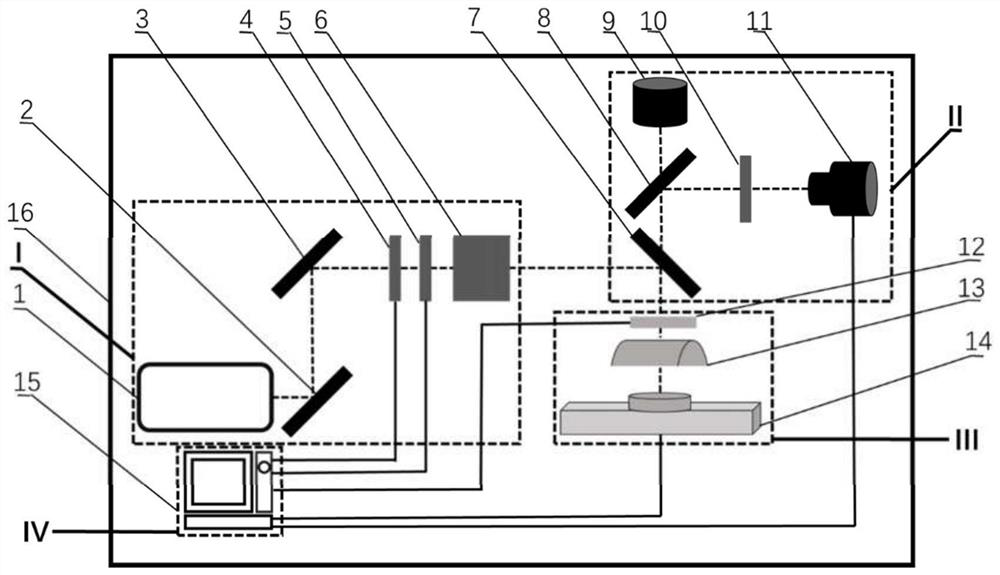

[0019] See attached figure 1 , the present invention is composed of a light source system I, a sample monitoring system II, a sample processing system III and a control system IV. The experimental device 16 realizes the preparation of a periodic stripe structure on the glass surface covered with an ITO film. Described light source system 1 is made up of the light path that femtosecond laser light source 1 is connected with the first high reflection mirror 2, the second high reflection mirror 3, electronic shutter 4, the first half-wave plate 5 and Glan prism 6 successively, adopts the first The half-wave plate 5 adjusts the laser polarization direction to be parallel to the Y axis, so that the direction of the scribe lines on the sample surface is parallel to the periodic nanostripes induced by the femtosecond laser. Move the sample at a constant speed along the Y-axis to form a large-area periodic fringe structure on the surface of the sample. The speed of the translation sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com