Method for regulating surface wettability of 3D printing piece made of PA2200 material by laser irradiation

A PA2200, laser irradiation technology, applied in 3D printing technology and medical application, laser processing field, can solve the problems of molded parts pollution, coating easy to fall off, wettability change of molded parts surface, etc., to achieve high controllability, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

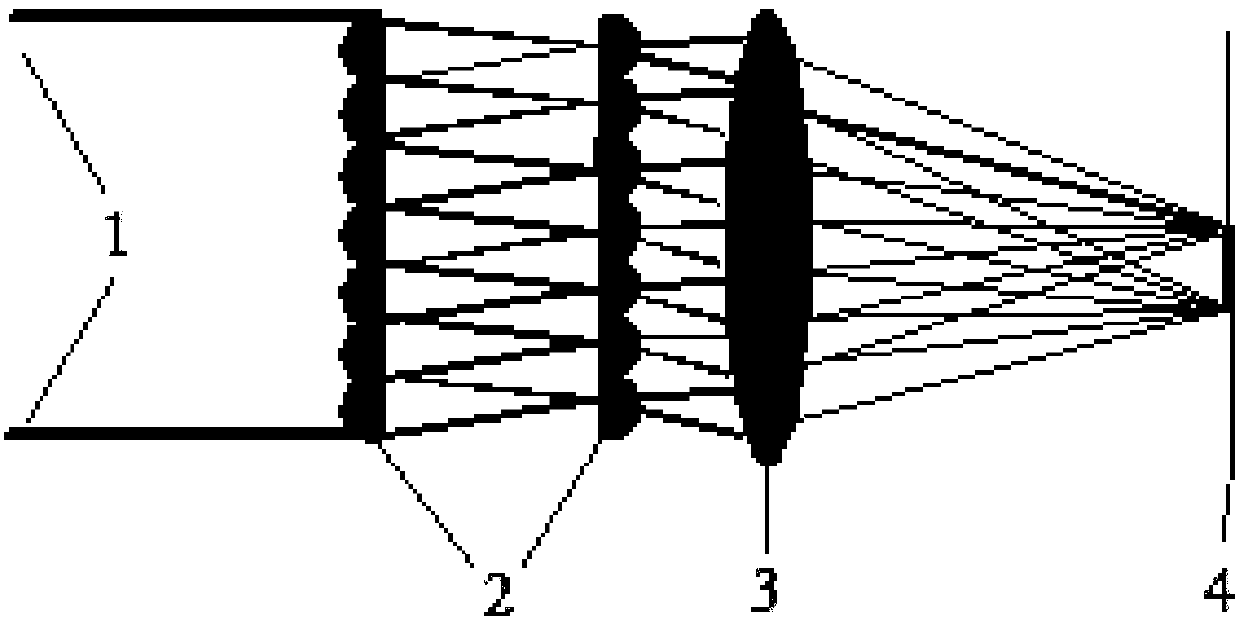

[0023] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0024] The first step: use SLS technology to prepare 3D printed parts of PA2200 material

[0025] This step is to prepare 3D prints of PA2200 materials. The specific process is divided into data preparation, printing, and subsequent cleaning:

[0026] 1) Data preparation: Use the magics software to prepare the model in STL format. After the model is ready, use the RP Tools slicing software to slice the model. After slicing, import it into the PSW software and save it as an eosjz file, and then import this file into the 3D printer EOS P396 machine PSW software and load this file, the data preparation process is completed;

[0027] 2) Printing: Before printing, the printer needs to pre-spread 9mm of powder and preheat for 2 hours. After the preheating is completed, it can be printed. During the printing process, the printer prints layer by layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com