Cobalt-free positive electrode material and preparation method and application thereof

A positive electrode material, diffraction method technology, applied in positive electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome preparation process, serious gas production, etc., to increase the rate of charge and discharge, reduce gas production, increase capacity and The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a specific embodiment, the present invention provides a method for preparing a cobalt-free positive electrode material, the preparation method comprising the following steps:

[0041] (1) Lithium source (LiCO 3 and / or LiOH), precursor Ni x mn 1-x (OH) 2 (0.2≤x≤0.95) and the dopant are mixed evenly with a high-speed mixer, put into a box-type atmosphere furnace for a sintering, the sintering temperature is 750-1000°C, crushed after the sintering is completed, and airflow crushed after the crushing is completed The machine is crushed, and after the crushing is completed, the first-fired material is obtained;

[0042] The dopant can be ZrO 2 、TiO 2 , TeO, TeO 2 , SbO 2 , Sb 2 o 3 , Y 2 o 3 、 Bi 2 o 3 or Ta 2 o 5 at least one of;

[0043] (2) Mix the primary sintered product with a coating agent, and perform secondary sintering at 600-800°C to obtain a cobalt-free positive electrode material;

[0044] Wherein, the coating agent can be Al 2 o 3 , ZrO 2...

Embodiment 1

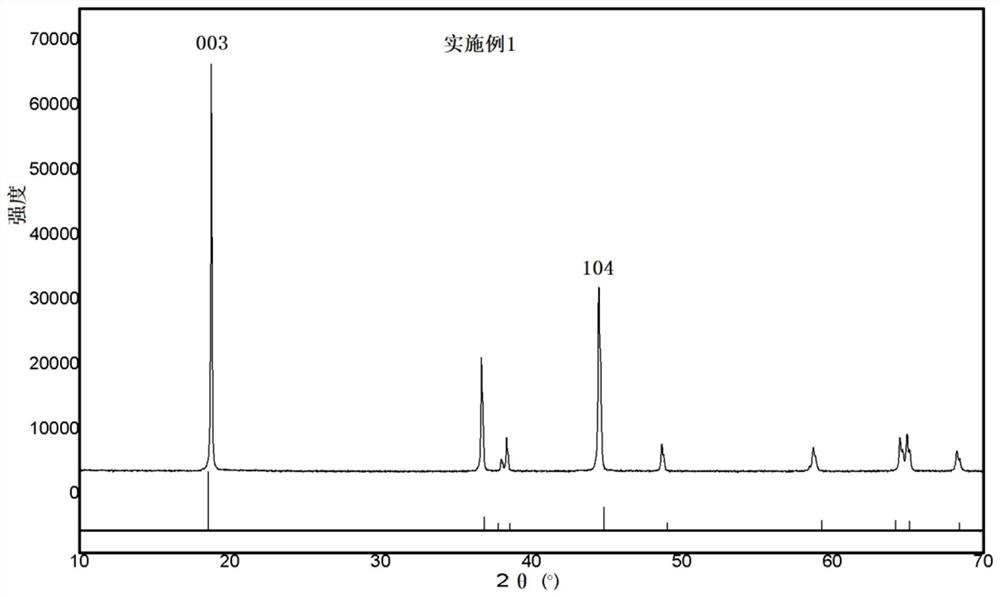

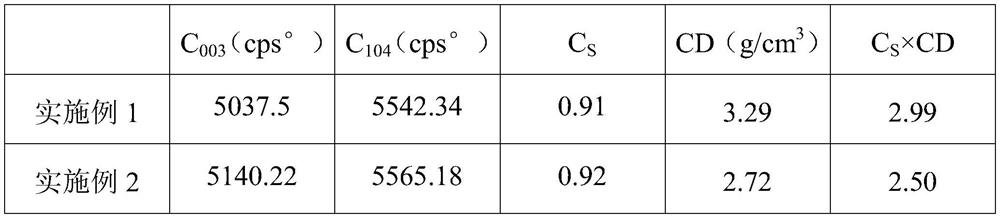

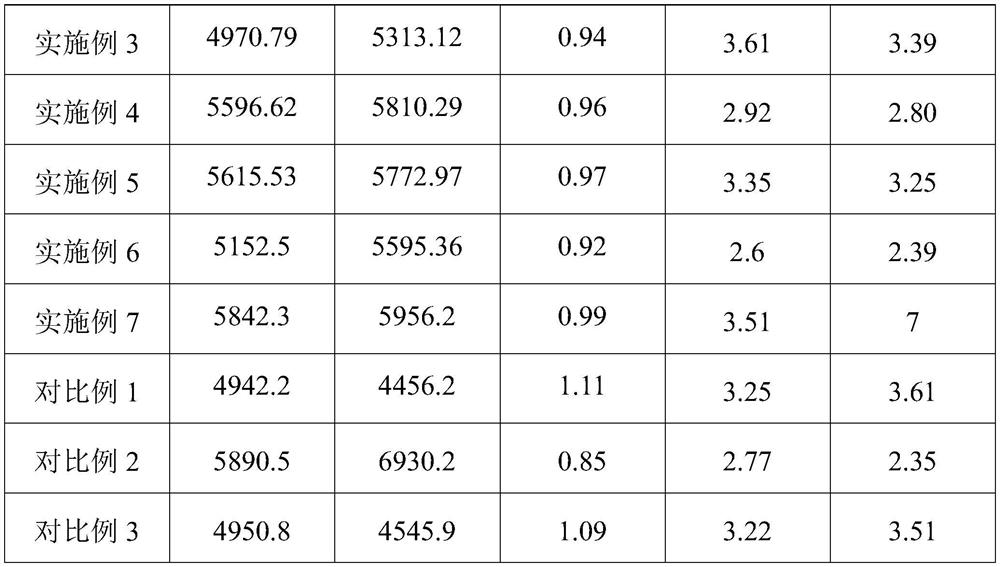

[0046] This embodiment provides a cobalt-free positive electrode material (specific surface area is 0.85m 2 / g, the D50 of the primary particles is 2.3 μm), the chemical formula of the cobalt-free cathode material is Li 1.1 Ni 0.55 mn 0.45 o 2 , C S =C 003 / C 104 , C 003 is the peak area of the 003 characteristic diffraction peak in the X-ray diffraction pattern of the cobalt-free cathode material, C 104 is the peak area of the 104 characteristic diffraction peak in the X-ray diffraction pattern of the cobalt-free positive electrode material; CD is the maximum compaction density that the particles in the cobalt-free positive electrode material do not break to reach, wherein, C S 、C 003 、C 104 , CD, C S The numerical results of ×CD are shown in Table 1.

[0047] The preparation method of the cobalt-free positive electrode material is based on the preparation method provided in the above specific embodiment:

[0048] Wherein, wherein, the precursor is Ni 0.55 mn...

Embodiment 2

[0051] This embodiment provides a cobalt-free positive electrode material (specific surface area is 1m 2 / g, the D50 of the primary particles is 2 μm), the chemical formula of the cobalt-free cathode material is Li 1.1 Ni 0.55 mn 0.45 o 2 , C S =C 003 / C 104 , C 003 is the peak area of the 003 characteristic diffraction peak in the X-ray diffraction pattern of the cobalt-free cathode material, C 104 is the peak area of the 104 characteristic diffraction peak in the X-ray diffraction pattern of the cobalt-free positive electrode material; CD is the maximum compaction density that the particles in the cobalt-free positive electrode material do not break to reach, wherein, C S 、C 003 、C 104 , CD, C S The numerical results of ×CD are shown in Table 1.

[0052] The preparation method of the cobalt-free positive electrode material is based on the preparation method provided in the above specific embodiment:

[0053] Wherein, wherein, the precursor is Ni 0.55 mn 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com