Tower crane turntable support welding method

A welding method and tower crane technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large overall structure of supports, low safety, and difficulty in ensuring accuracy, so as to improve position accuracy and ensure welding Accuracy, reducing the effect of welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

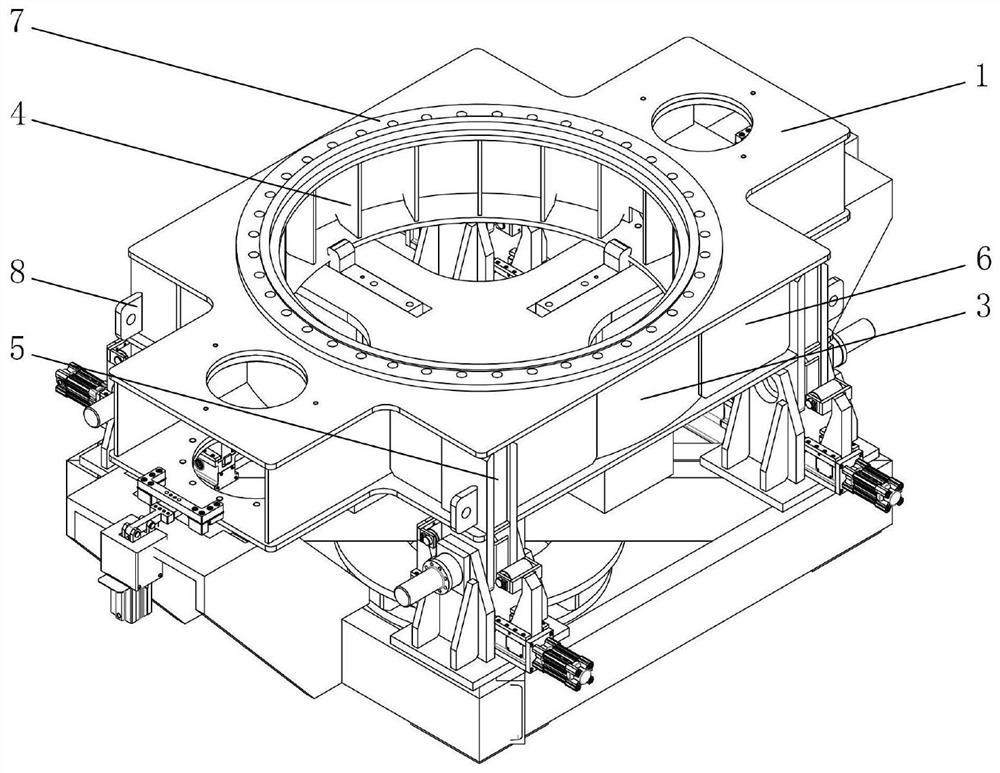

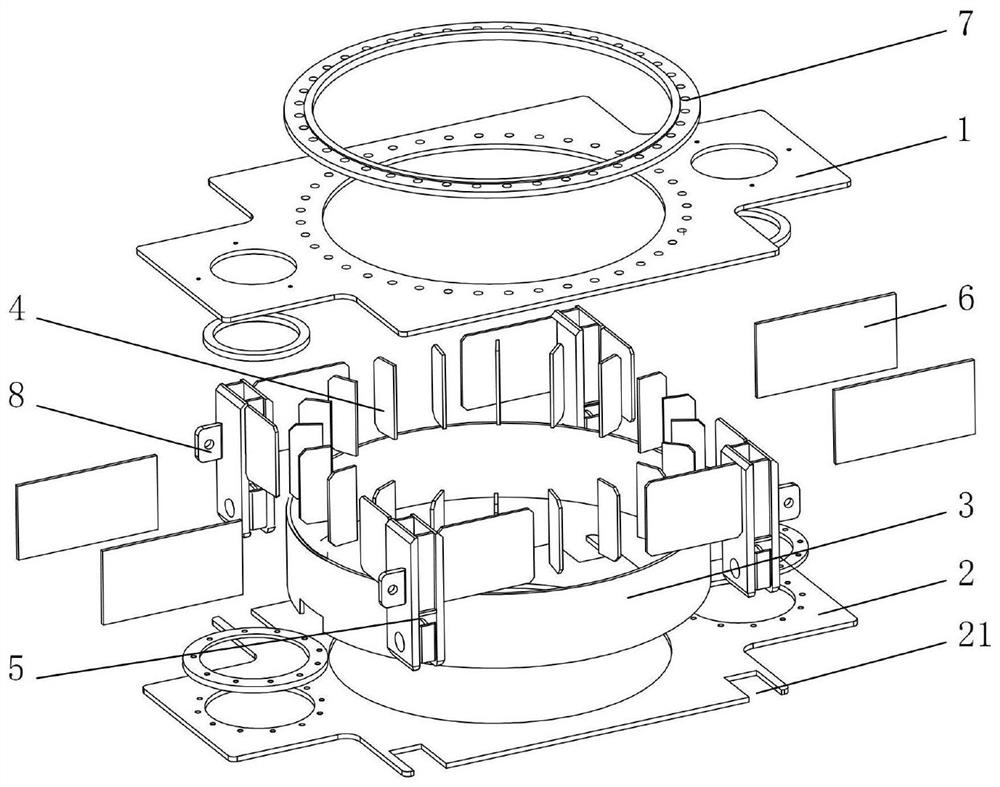

[0034] Such as figure 1 and figure 2 As shown, the welding method of the tower crane turret support in this embodiment, the support includes an upper cover plate 1, a lower cover plate 2, a circular sealing plate 3, a rib plate 4, a leg assembly 5, a surrounding plate 6 and a seat ring 7 , the welding method is sequentially from bottom to top leg assembly 5 and lower cover plate 2, lower cover plate 2 and circular sealing plate 3, circular sealing plate 3 and rib plate 4, lower cover plate 2 and surrounding plate 6, circular The place to be welded between the shape sealing plate 3 and the upper cover plate 1, the coaming plate 6 and the upper cover plate 1 and the upper cover plate 1 and the seat ring 7 is spot welded, and the place to be welded to be spot welded is welded.

[0035] The welding method of this embodiment does not need to group multiple workpieces in a scribing manner at the same time, only when the welding process of a certain workpiece is performed, the work...

Embodiment 2

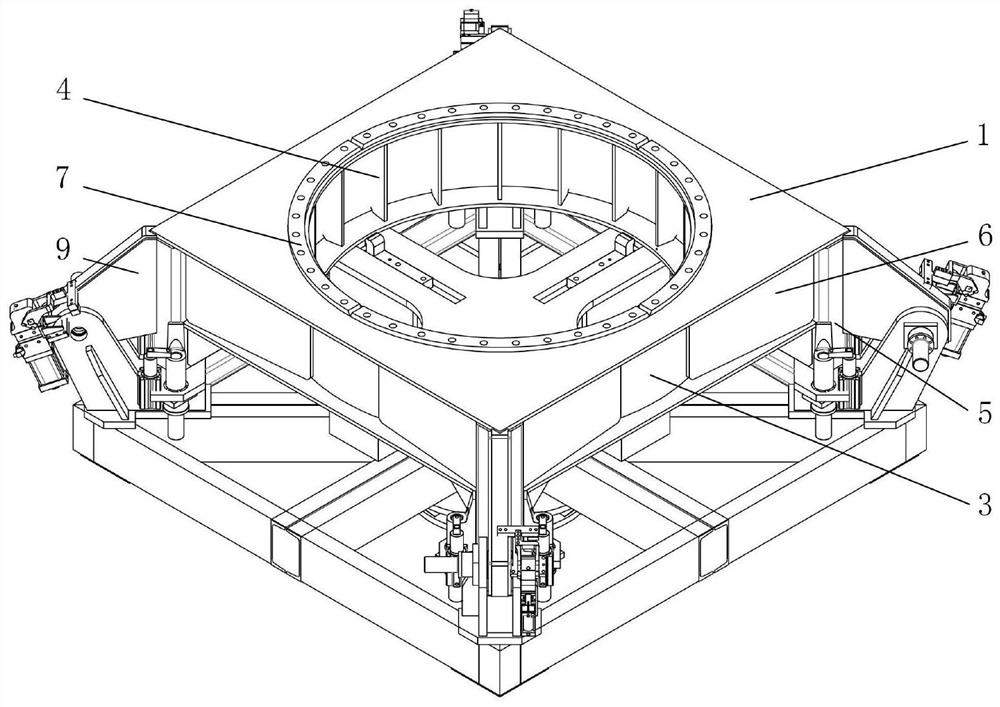

[0050] In this embodiment, the support is the lower support of the tower crane turntable, such as image 3 and Figure 4 As shown, the welding steps of the lower support are roughly the same as those in Embodiment 1, the difference is that the lower support also includes jacking ears 9, and the welding method of the support also includes step S8 performed after step S7: placing the jacking ears 9 Position and clamp on the outrigger assembly 5, and weld the to-be-welded part between the outrigger assembly 5 and the jacking ear 9. In this way, the jacking ears 9 are prevented from interfering with the clamping of the outrigger assembly 5, and the interference of the jacking ears 9 with the welding torch of the welding robot can also be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com