Simple and environment-friendly mechanical part machining polishing device convenient to move

An environmentally friendly technology for mechanical parts, applied in the field of mechanical parts processing, can solve the problems of dust cannot be collected and processed in a timely manner, poor connection adjustment, and inability to adjust the position, so as to improve operability, facilitate movement, Fast sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

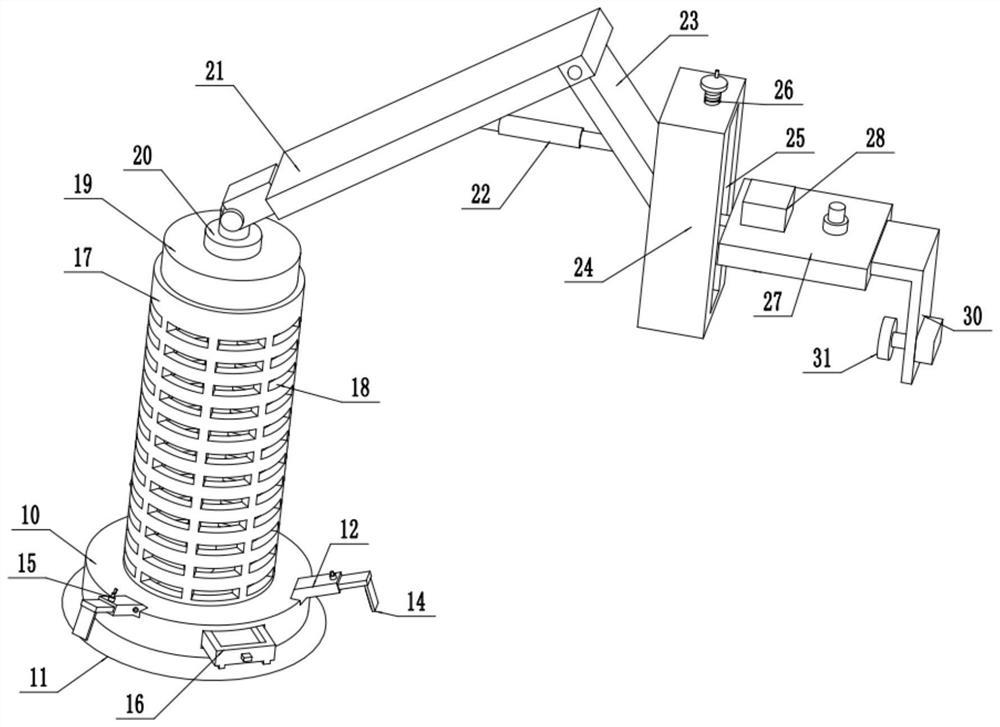

[0023] see Figure 1-3 , a simple and easy-to-move environment-friendly processing and grinding device for mechanical parts, including a base 10, a grinding knife 31, and a grinding motor 36; A suction cup 11 for improving the suction force of the base 10 is installed. The top edge of the base 10 is outwardly connected with three groups of telescopic splints 12 distributed at equal intervals through a rotating shaft, and one end of the rotating shaft is provided with a damping device for limiting its rotation. The end of the telescopic splint 12 is telescopically connected with a limiting plate 14 in an L-shaped structure, and the limiting plate 14 is locked at a position to be fixed, and then fixed by rotating the telescopic splint 12 . A tightening knob 15 for limiting the expansion and contraction of the limiting plate 14 is arranged on the outer top of the telescopic splint 12 . The top of the seat column 17 is fixedly equipped with a top seat 19, and the inner middle pa...

Embodiment 2

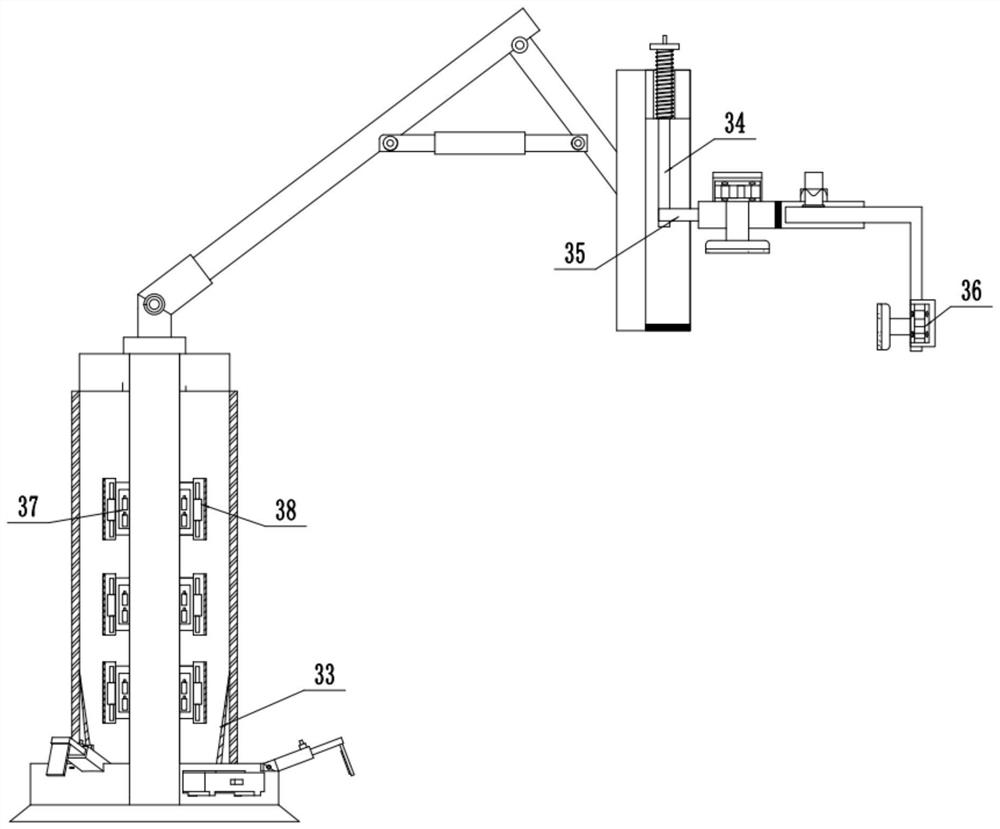

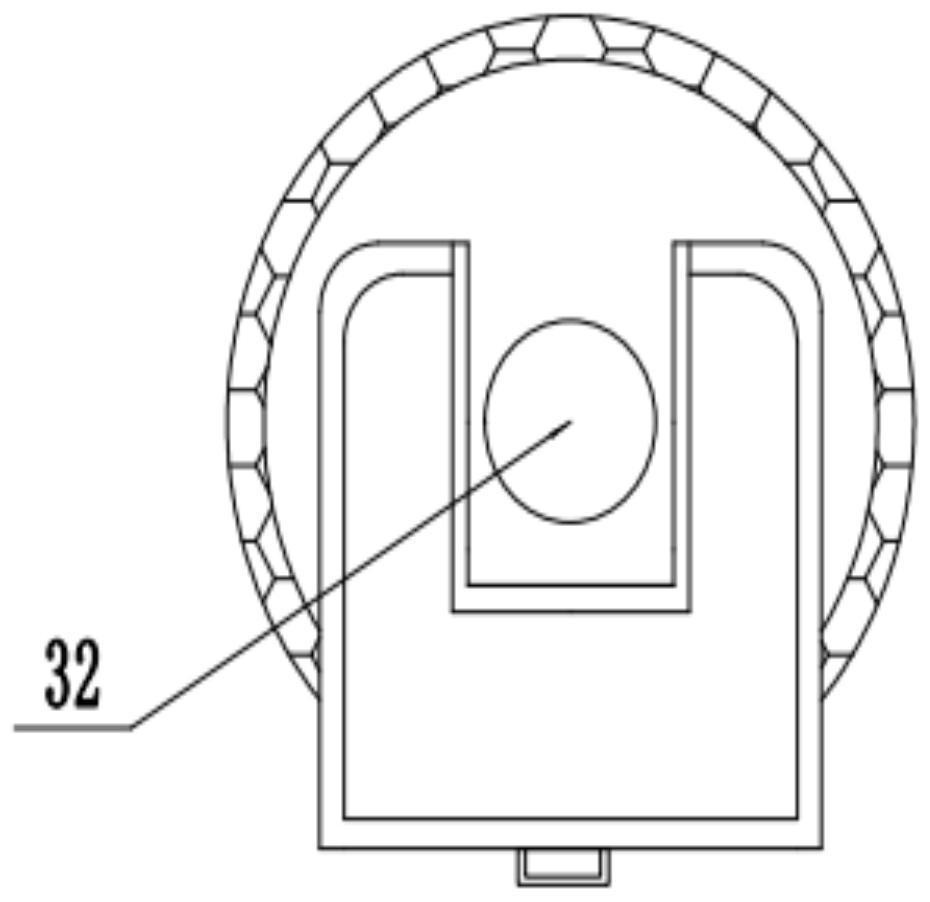

[0025]On the basis of Embodiment 1, several groups of dust suction ports 18 are evenly opened on the outer surface of the base 10, and a group of vertical columns 32 are fixedly installed in the inner middle of the base 10, and the outer surfaces of the columns 32 are from top to bottom, etc. Multiple groups of exhaust fans 37 are fixedly installed at intervals, the output ends of the exhaust fans 37 are facing the outside of the base 10 and a layer of windshield 38 for filtering impurities is fixedly installed, and the external dust gas is sucked into the base 10 by starting the exhaust fans 37 to operate internal. The bottom of the base 10 is provided with a dust collection bin, and a dust drawer 16 is slidably connected to the outside of the dust collection bin. The top of the dust collection bin is fixedly equipped with a guide plate 33 in a trumpet-shaped structure for The dust sucked by the exhaust fan 37 from the outside falls into the dust drawer 16 under the effect of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com