Building cement uniform stirring device

A technology for uniform mixing and construction, applied in cement mixing devices, clay preparation devices, filtration and separation, etc., can solve problems such as slow mixing speed, and achieve the effect of increasing applicability, increasing practicability, and speeding up mixing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

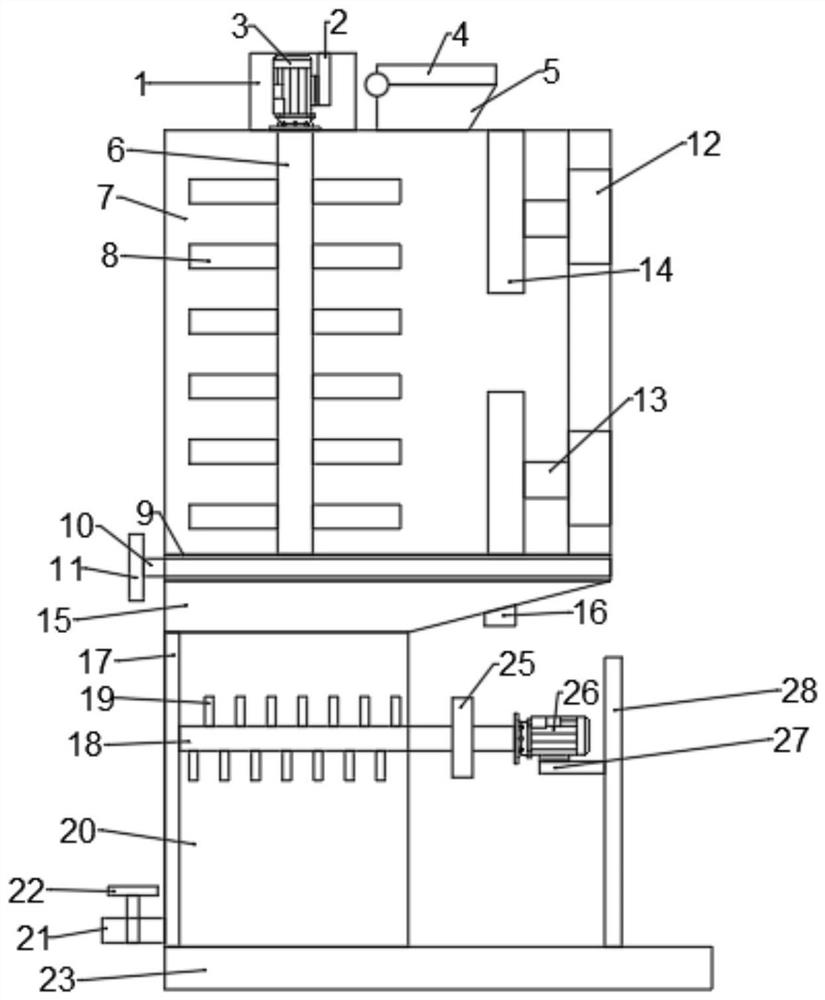

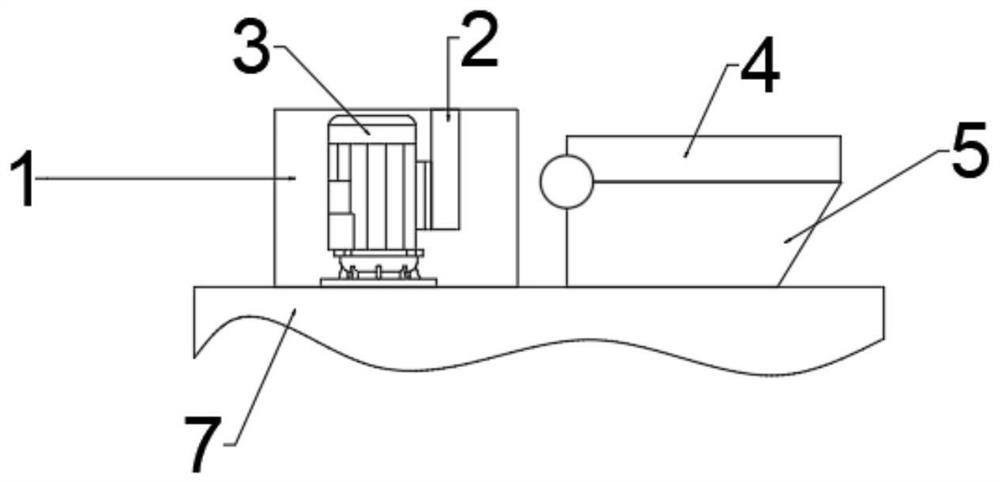

[0033] refer to Figure 1 to Figure 4 , a cement uniform mixing device for construction, comprising a mixing box 7, a power box 1 is connected with a bolt above the mixing box 7, a first fixing plate 2 is connected with a bolt at the top of the inside of the power box 1, and the left side of the first fixing plate 2 The first motor 3 is connected by bolts, the output end shaft of the first motor 3 is connected with the stirring shaft 6, the stirring shaft 6 runs through the upper shell wall of the stirring box 7, the stirring rod 8 is connected with the bolts on the stirring shaft 6, the stirring box 7 The upper right bolt is connected with the feed port 5, the feed port 5 is internally connected with the mixing box 7, and the inner right side of the mixing box 7 is connected with several hydraulic pipes 12, and the left end of the hydraulic pipe 12 is plugged and connected with a hydraulic telescopic pipe 13. The end of the hydraulic telescopic tube 13 away from the hydraulic...

Embodiment 2

[0041] refer to Figure 5 , a cement uniform mixing device for construction. Compared with Embodiment 1, this embodiment has a driving gear 25 fixed on one end of the sliding stirring shaft 18 close to the second motor 26, and a driven gear 29 meshingly connected to the bottom of the driving gear 25. , the central axis of the driven gear 29 is fixed with a transmission shaft 30, and one end shaft of the transmission shaft 30 away from the driven gear 29 is fixed with a sliding gear 31, and the rear side of the sliding gear 31 is meshed with a rack 24, the rack 24 and the base plate 23 Bolt connection, use the sliding stirring shaft 18 to rotate, so that the driving gear 25 drives the driven gear 29 to rotate, so that the transmission shaft 30 drives the sliding gear 31 to rotate, so that the sliding gear 31 moves up and down on the rack 24, thereby completing the concrete mixing. Fully stir and mix well to increase its practicability.

[0042] Working principle: use the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com