Polypropylene foamed bead with different and selectively distributed cell sizes and preparation method thereof

A technology of foaming beads and polypropylene, applied in the field of polypropylene foaming beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

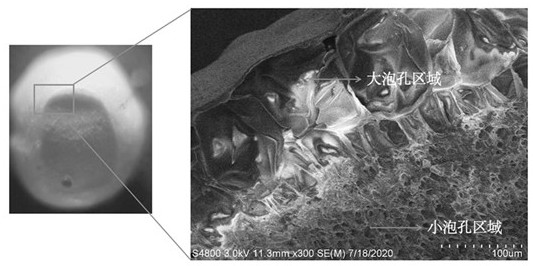

Image

Examples

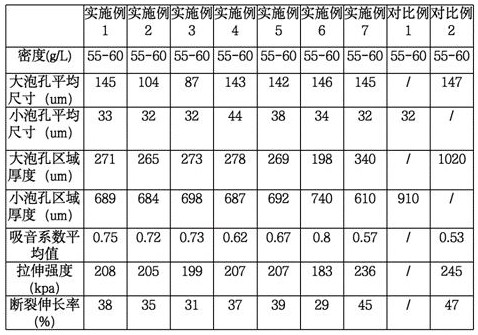

Embodiment 1

[0025] Preparation of polypropylene microparticles with different cell sizes and selective directional distribution of large and small cells: uniformly mix 77 parts by mass of low-melt polypropylene, 20 parts by mass of calcium carbonate and polytetrafluoroethylene compound, 3 parts by mass Maleic anhydride grafted polypropylene, 0.1 parts by mass of polyethylene wax and 0.1 parts by mass of β-(3.5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate. Among them, the selected low melting point polypropylene melt point is 3g / min, the mass ratio of calcium carbonate and polytetrafluoroethylene in the compound nucleating agent is 95:5, the particle size of calcium carbonate is 30 microns, polytetrafluoroethylene The particle size of vinyl fluoride is 7 microns, and the graft ratio of maleic anhydride grafted polypropylene is 0.05%. Put the above resins and additives into the extruder host.

[0026] Evenly mix 99 parts by mass of high melting point polypropylene, 0.01 part b...

Embodiment 2

[0031] Except that 0.01 parts by mass of aluminum hydroxide is used as a nucleating agent in the outer polypropylene resin, the same method as in Example 1 is used to prepare polypropylene foamed resin beads with different cell sizes and selective distribution of large and small cells. and sheet metal parts.

Embodiment 3

[0033] Except that 0.1 parts by mass of aluminum hydroxide is used as a nucleating agent in the outer layer of polypropylene resin, the same method as in Example 1 is used to prepare polypropylene foamed resin beads with different cell sizes and selective distribution of large and small cells. and sheet metal parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com