Solid wood composite door

A technology of solid wood composite and solid wood, which is applied to doors, windows/doors, fire doors, etc., can solve the problems of fire prevention, heat insulation, and sound insulation of neglected interior doors, and achieve long service life, strong anti-deformation ability in all directions, and enhanced noise reduction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

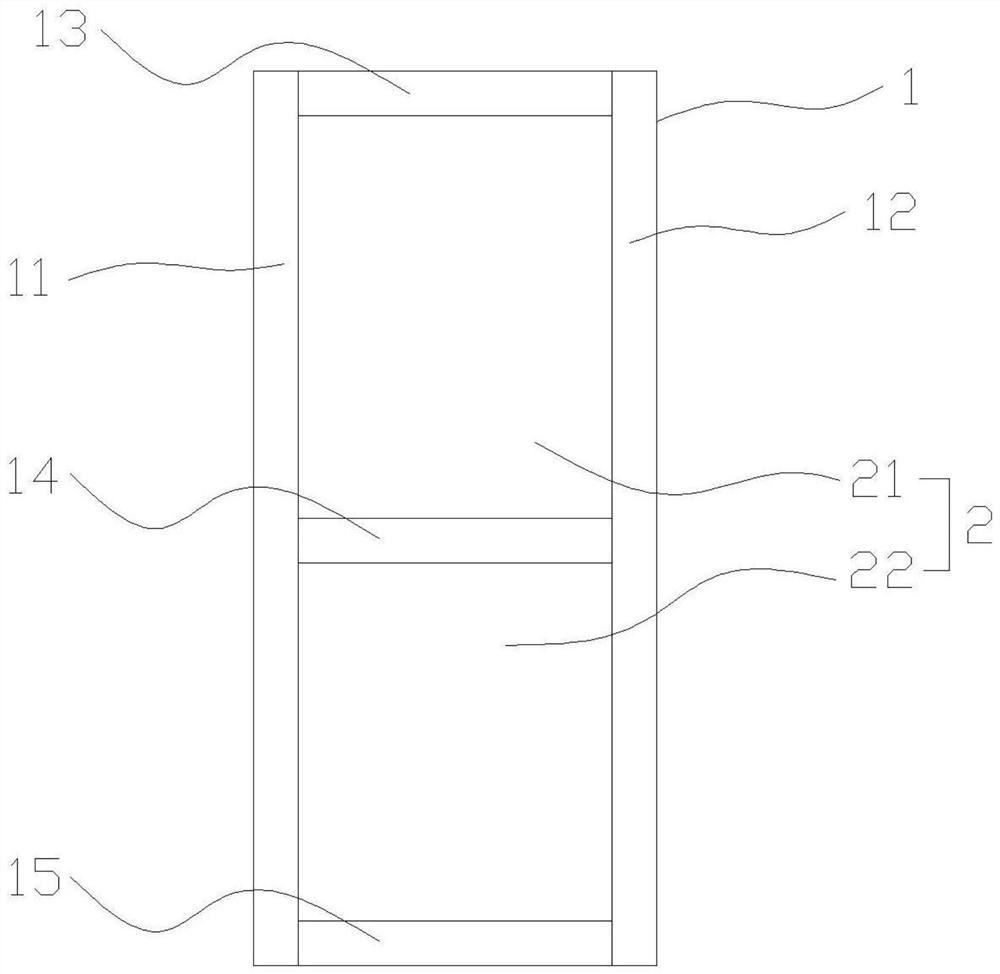

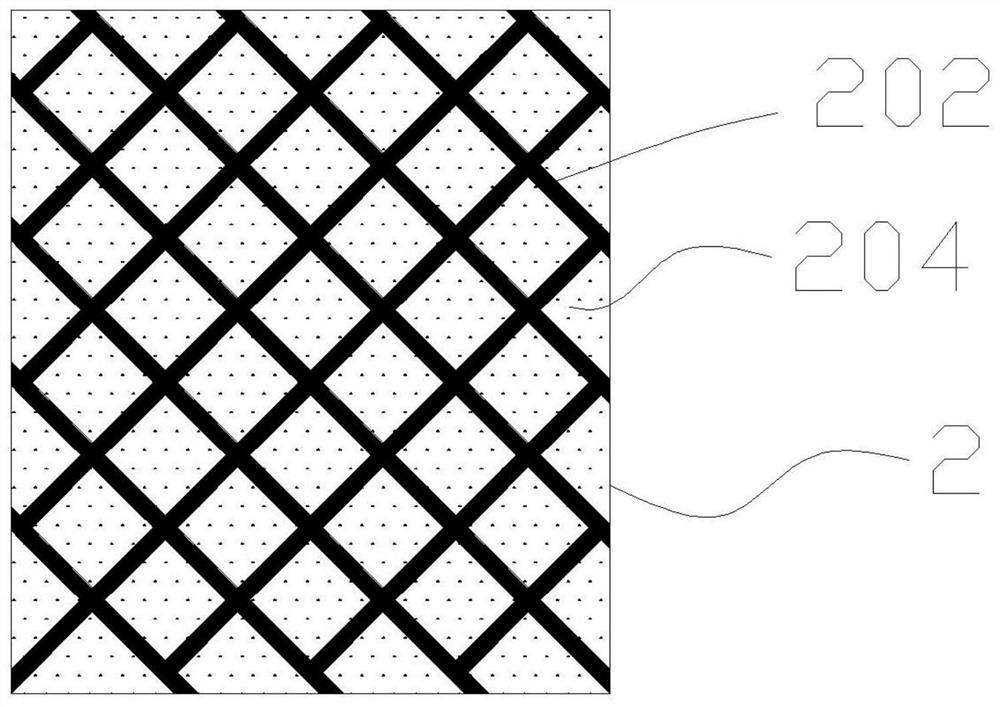

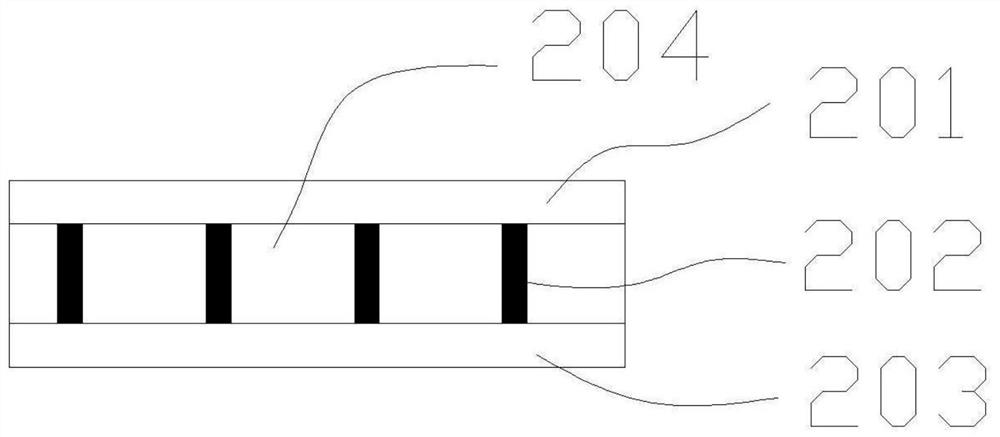

[0022] Please refer to the attached Figure 1~3 Schematic diagram of the structure, a solid wood composite door that is dry, scented, disinfected, and insect-proof, which includes a door leaf (1) and a door core board (2), the overall thickness of the door leaf (1) and the door core board (2) is 40mm, and the door leaf ( 1) Including two left door sides (11) and right door sides (12), the two door sides are fixed vertically by the upper crosspiece (13), middle crosspiece (14) and lower crosspiece (15). The sides and crosspieces are spliced and processed by solid wood strips. The middle crosspiece (14) is vertically processed with a plurality of 18mm diameter through holes neatly arranged. The interval between the through holes is 80mm. Cavity (204), door core board (2) comprises upper door core board (21) and lower door core board (22), and each door core board is all made up of three layers, is respectively solid wood puzzle layer 1 (201), Solid wood keel (202), solid wood...

Embodiment 2

[0024] Please refer to the attached Figure 1~3 Schematic diagram of the structure, a solid wood composite door with fireproof performance, which includes a door leaf (1) and a door core board (2). The overall thickness of the door leaf (1) and door The left door side (11) and the right door side (12), the two door sides are fixed vertically by the upper crosspiece (13), the middle crosspiece (14), and the lower crosspiece (15). Made of spliced solid wood strips, the middle crosspiece (14) is vertically processed with a plurality of 18mm diameter through holes neatly arranged, the interval between the through holes is 80mm, and the through holes connect the cavities (204) in the upper and lower core boards , the door core board (2) comprises an upper door core board (21) and a lower door core board (22), and each door core board is composed of three layers, which are respectively solid wood panel layer 1 (201), solid wood keel (202) , Solid wood panel layer 2 (203), the cav...

Embodiment 3

[0026] Please refer to the attached Figure 1~3 Schematic diagram of the structure, a solid wood composite door with sound insulation performance, which includes a door leaf (1) and a door core board (2). The overall thickness of the door leaf (1) and the door core board (2) is 45mm. The left door side (11) and the right door side (12), the two door sides are fixed vertically by the upper crosspiece (13), the middle crosspiece (14), and the lower crosspiece (15). Made of spliced solid wood strips, the middle crosspiece (14) is vertically processed with a plurality of 15mm diameter through holes neatly arranged, the interval between the through holes is 60mm, and the through holes connect the cavities (204) in the upper and lower core boards , the door core board (2) comprises an upper door core board (21) and a lower door core board (22), and each door core board is composed of three layers, which are respectively solid wood panel layer 1 (201), solid wood keel (202) , Soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com