Method for detecting grade of diamond micro-powder by utilizing Raman spectroscopy and application of method in detecting grade of diamond micro-powder

A Raman spectroscopic detection, diamond micropowder technology, applied in Raman scattering, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of uncertainty, troublesome quality control, etc., and achieve the effect of an efficient detection method

Active Publication Date: 2020-12-01

郑州建斌电子科技有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This brings great trouble and uncertainty to the quality control of both the production unit and the user unit of the micropowder.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

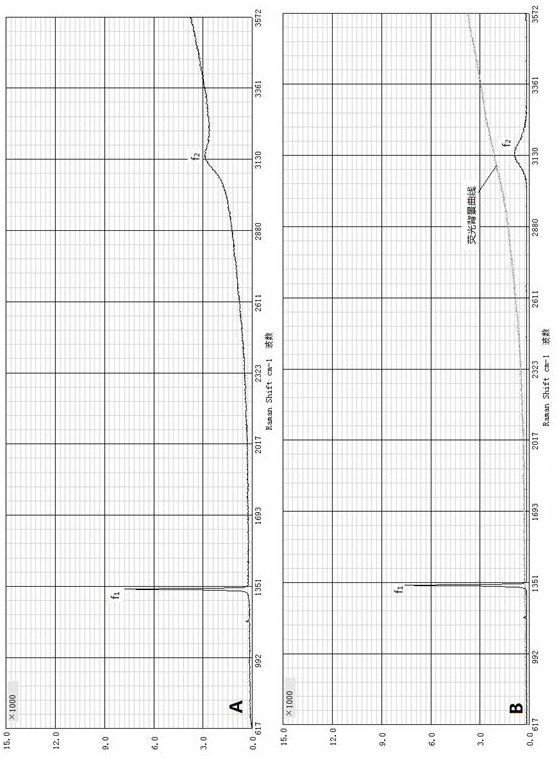

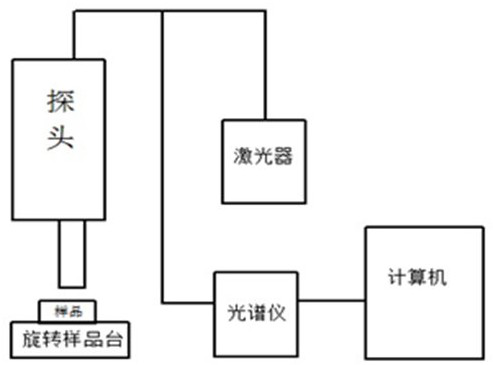

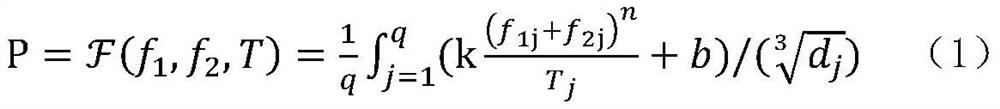

[0045] According to the method provided by the present invention, the Raman spectrum information is collected and tested and analyzed.

[0046] Select 4 samples of 40 / 45 diamond abrasive, numbered D1, D2, D3, D4 respectively, each sample is 200 grams.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for detecting the grade of diamond micro-powder by utilizing Raman spectroscopy and application of the method in detection of the grade of the diamond micro-powder. Themethod comprises the following steps: detecting a fluorescence intensity value and a Raman spectrum intensity value of a diamond micro-powder sample; and calculating according to a formula to obtainthe grade of the diamond micro-powder. According to the method, the grade of the diamond micro-powder can be accurately detected, the quality of the diamond micro-powder is controlled, and the methodis particularly helpful to the use effect of the diamond micro-powder. The method is convenient and fast, and has a good application effect.

Description

technical field [0001] The invention belongs to the technical field of superhard material detection, and in particular relates to a method for detecting the grade of diamond micropowder by using Raman spectrum and its application in detecting the grade of diamond micropowder. Background technique [0002] Diamond micropowder has high hardness and good wear resistance, and is widely used in cutting, grinding, drilling, polishing, etc. With the development and progress of science and technology, the market demand for diamond micropowder is increasing, and the quality requirements are also getting higher and higher. For diamond micropowder, factors affecting the quality include particle strength (grade), particle size composition, particle shape, impurity content and other factors. For the particle size composition, particle shape, impurity content and other items of the micropowder, there are relatively mature inspection methods, but there is no way to inspect the particle st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/65G01N21/64

CPCG01N21/65G01N21/64

Inventor 周建斌张学涛周波

Owner 郑州建斌电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com