Diaphragm and battery comprising same

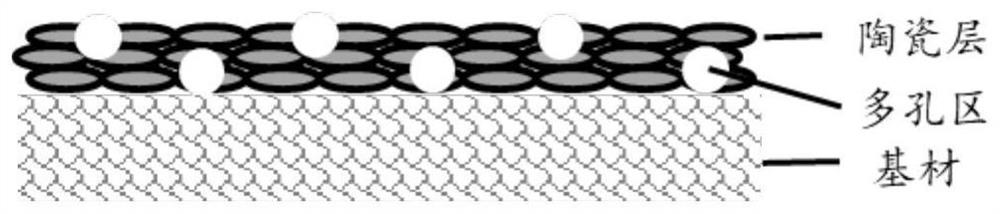

A separator and ceramic coating technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve problems such as the performance reduction of separator needle punching strength and thermal shrinkage, affecting battery self-discharge, safety and other performance problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

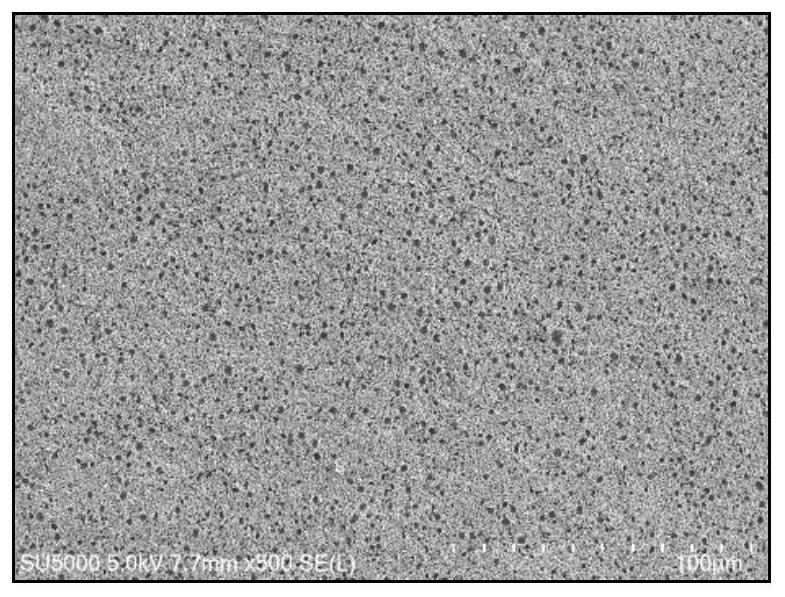

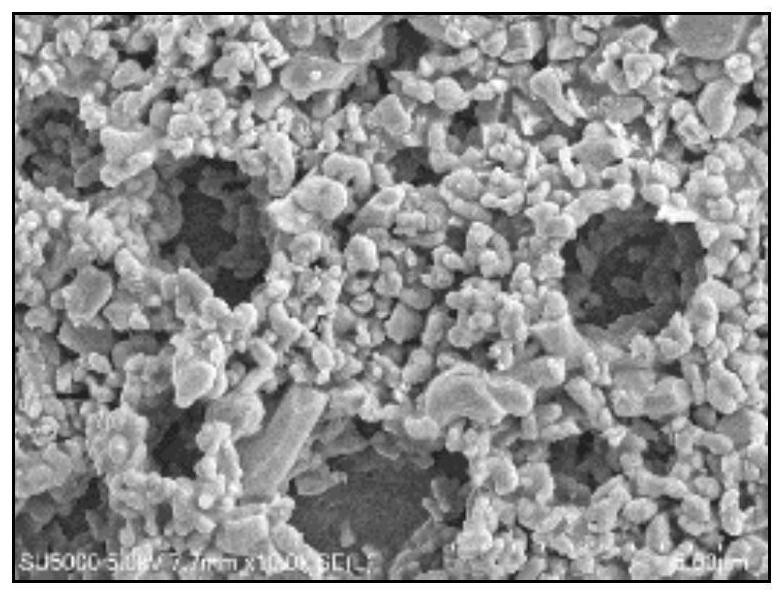

[0061] 20kg of alumina, 0.32kg of sodium carboxymethylcellulose, 1kg of polymethyl methacrylate, 0.1kg of polyvinylpyrrolidone, and 78.58kg of deionized water were mixed together to obtain a ceramic slurry;

[0062] Take 10 kg of the above-mentioned ceramic slurry, add 0.2 kg of heat-sensitive polymer microspheres (the particle diameter of the heat-sensitive polymer microsphere is 1.5 μm, and the heat-sensitive temperature is 110° C.), to obtain a modified ceramic slurry;

[0063] The above-mentioned modified ceramic slurry was coated on the first surface of the diaphragm base layer by micro-gravure, dried at 60° C. for 1 minute, and then subjected to high temperature treatment at 120° C. for 5 minutes to obtain the diaphragm.

[0064] The thickness of the diaphragm base layer in the diaphragm is 9 μm, the material system of the diaphragm base layer is PE, and the porosity is 40%.

[0065] The thickness of the ceramic coating in the diaphragm is 3 μm, the surface and / or inside...

Embodiment 2

[0068] 20kg of alumina, 0.32kg of sodium carboxymethylcellulose, 1kg of polymethyl methacrylate, 0.1kg of polyvinylpyrrolidone, and 78.58kg of deionized water were mixed together to obtain a ceramic slurry;

[0069] Take 10 kg of the above-mentioned ceramic slurry, add 0.4 kg of heat-sensitive polymer microspheres (the particle size of the heat-sensitive polymer microspheres is 1.5 μm, and the heat-sensitive temperature is 110° C.), to obtain a modified ceramic slurry;

[0070] The above-mentioned modified ceramic slurry was coated on the first surface of the diaphragm base layer by micro-gravure, dried at 60° C. for 1 minute, and then subjected to high temperature treatment at 122° C. for 5 minutes to obtain the diaphragm.

[0071] The thickness of the diaphragm base layer in the diaphragm is 9 μm, the material system of the diaphragm base layer is PE, and the porosity is 40%.

[0072] The thickness of the ceramic coating in the diaphragm is 3 μm, the surface and / or inside of...

Embodiment 3

[0075] 20kg of alumina, 0.32kg of sodium carboxymethylcellulose, 1kg of polymethyl methacrylate, 0.1kg of polyvinylpyrrolidone, and 78.58kg of deionized water were mixed together to obtain a ceramic slurry;

[0076] Take 10 kg of the above-mentioned ceramic slurry, add 0.6 kg of heat-sensitive polymer microspheres (the particle diameter of the heat-sensitive polymer microsphere is 1.5 μm, and the heat-sensitive temperature is 110° C.), to obtain a modified ceramic slurry;

[0077] The above-mentioned modified ceramic slurry was coated on the first surface of the diaphragm base layer by micro-gravure, dried at 60° C. for 1 minute, and then subjected to high temperature treatment at 124° C. for 5 minutes to obtain the diaphragm.

[0078] The thickness of the diaphragm base layer in the diaphragm is 9 μm, the material system of the diaphragm base layer is PE, and the porosity is 40%.

[0079] The thickness of the ceramic coating in the diaphragm is 3 μm, the surface and / or inside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com