Energy-saving PTC electrothermal film

An electric heating film and energy-saving technology, applied in the field of energy-saving PTC electric heating film, can solve the problems of inability to achieve energy saving effect, lack of protection of electric heating film, and shortened service life, so as to promote the discharge of waste and toxic substances and smooth blood circulation , fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

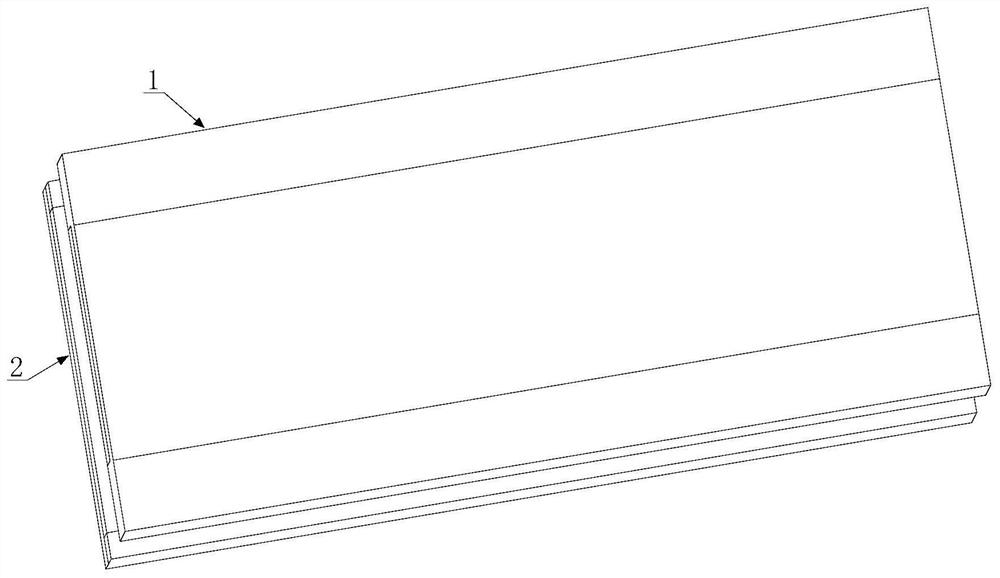

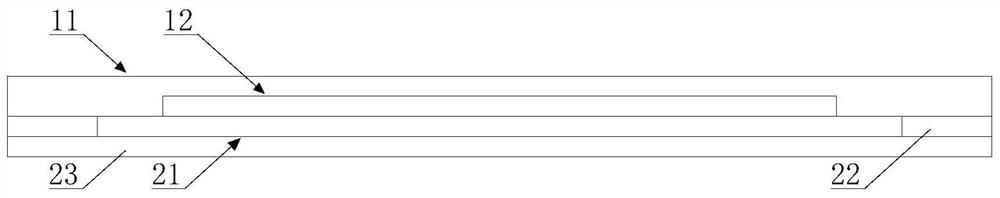

[0025] see Figure 1-2 , an energy-saving PTC electric heating film, including a cover film 1 and a bottom film 2, the bottom film 2 is provided under the cover film 1, the cover film 1 includes a protective film 11 and a semiconductor resistor 12, and a semiconductor resistor is provided inside the protective film 11 12. The protective film 11 is fixedly connected to the semiconductor resistor 12. The bottom film 2 includes a butt film 21, a sealing film 22 and an adhesive layer 23. Both sides of the butt film 21 are provided with a sealing film 22. The sealing film 22 and the butt film 21 The sealing film 22 is fixedly connected to the protective film 11, and the bottom end of the butt film 21 is fixedly connected to an adhesive layer 23, and the adhesive layer 23 is fixedly connected to the sealing film 22.

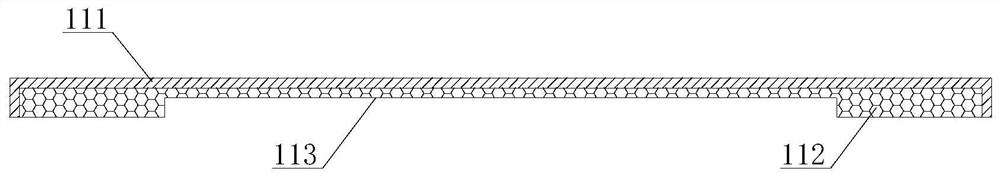

[0026] see Figure 3-4 The protective film 11 includes an outer film 111, an intermediate layer 112 and a built-in groove 113. The inner side of the outer layer film ...

Embodiment 2

[0029] see Figure 1-2 , an energy-saving PTC electric heating film, including a cover film 1 and a bottom film 2, the bottom film 2 is provided under the cover film 1, the cover film 1 includes a protective film 11 and a semiconductor resistor 12, and a semiconductor resistor is provided inside the protective film 11 12. The protective film 11 is fixedly connected to the semiconductor resistor 12. The bottom film 2 includes a butt film 21, a sealing film 22 and an adhesive layer 23. Both sides of the butt film 21 are provided with a sealing film 22. The sealing film 22 and the butt film 21 The sealing film 22 is fixedly connected to the protective film 11, and the bottom end of the butt film 21 is fixedly connected to an adhesive layer 23, and the adhesive layer 23 is fixedly connected to the sealing film 22.

[0030] see Figure 3-4The protective film 11 includes an outer film 111, an intermediate layer 112 and a built-in groove 113. The inner side of the outer layer film 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com