Vacuum pressing machine

A technology of vacuum laminating machine and vacuum pad, which is applied in the manufacture of multilayer circuits, electrical components, printed circuits, etc., which can solve the problems of poor bonding force, unqualified appearance, and unfavorable production, so as to prevent delamination and improve Effect of appearance quality and improvement of lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the following is based on preferred embodiments of the present invention, and is described in detail as follows in conjunction with the accompanying drawings:

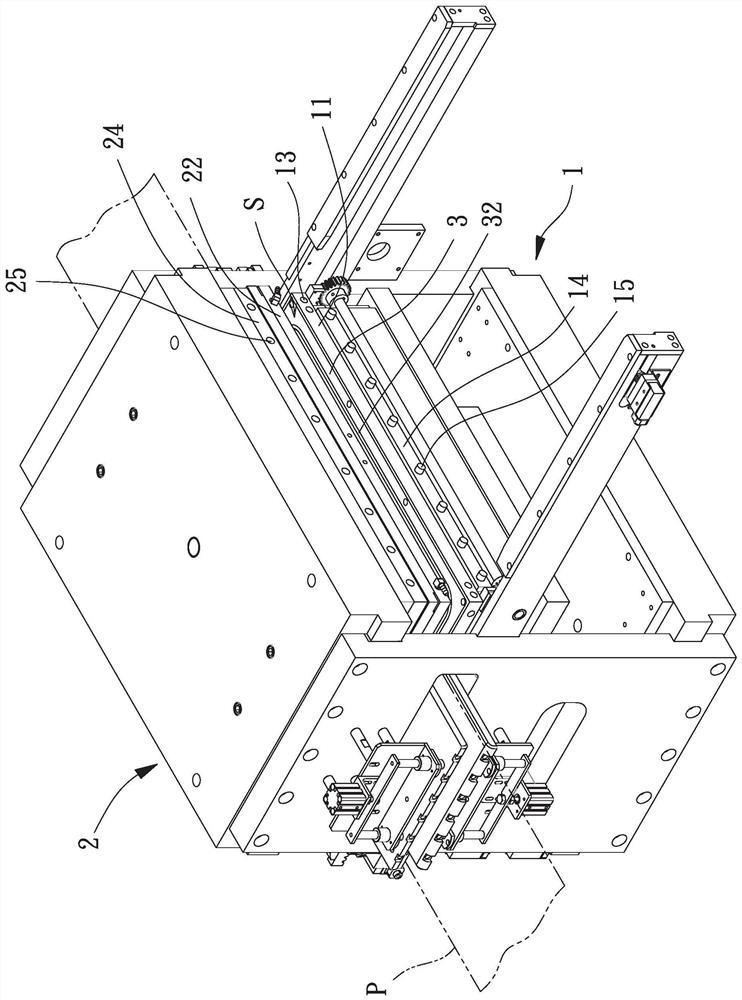

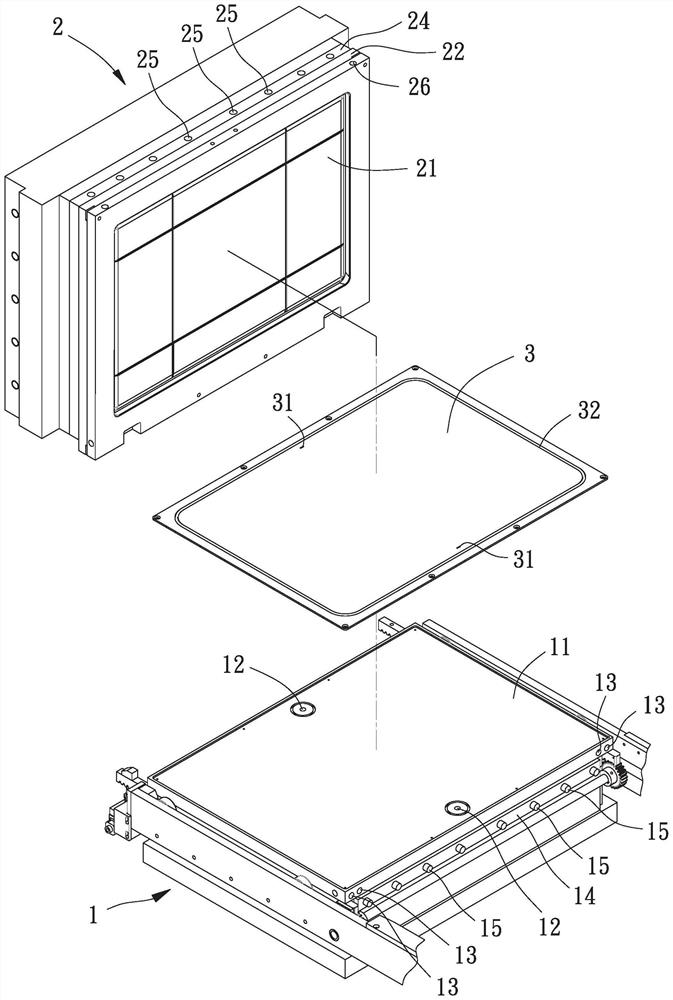

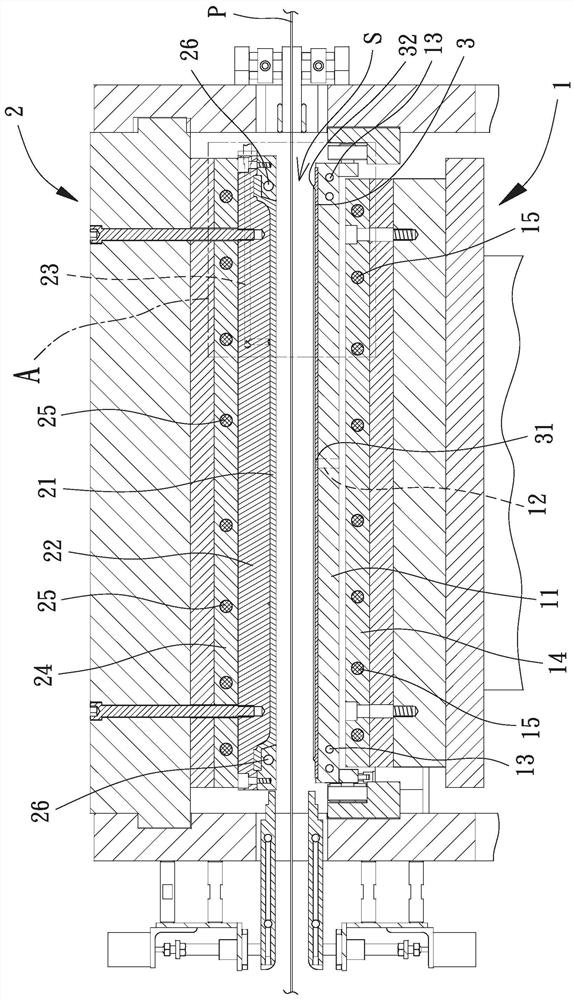

[0050] Please refer to figure 1 and 2 As shown, it is the first embodiment of the vacuum pressing machine of the present invention, including a loading platform 1, a pressing platform 2 and a vacuum pad 3, the pressing platform 2 is parallel and located on the loading platform 1, There is a gap between the loading platform 1 and the pressing platform 2 for a board P to pass through, the vacuum pad 3 is attached to the loading platform 1, and the upper surface of the vacuum pad 3 faces the board P and the pressing board. Combined platform 2.

[0051] Please refer to figure 2 and 3 As shown, the loading platform 1 can be reciprocated and vertically lifted. When the loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com