Cyclic deoxidation nitrogen-rich insect prevention device and method for closed bin

An anti-insect device and nitrogen-enriched technology, applied in edible seed preservation, food preservation, tobacco, etc., can solve problems such as dehydration damage, quality decline, etc., and achieve the effect of reducing operating load and process control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

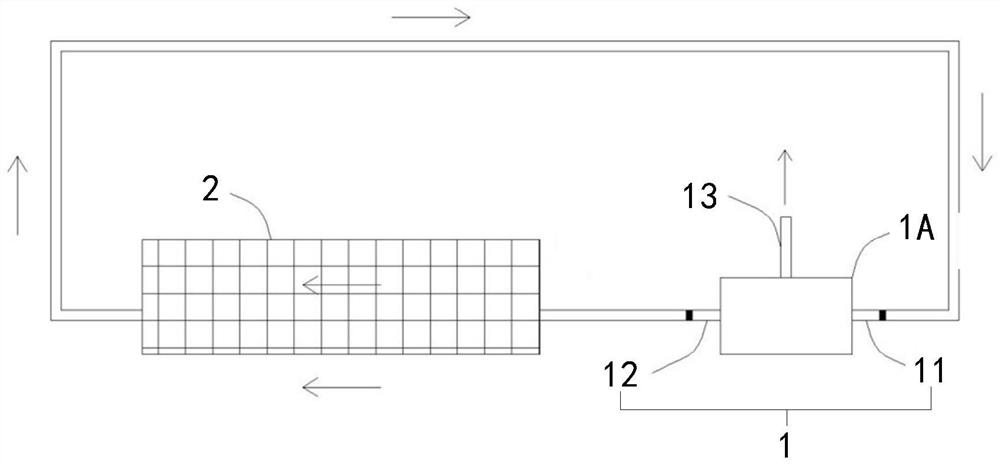

[0046] Such as figure 1 As shown, the circulating deoxygenation, nitrogen-enriching and insect-proofing device of the airtight chamber provided by the present invention includes a separation and removal unit 1;

[0047] The separation and removal unit 1 has a first gas inlet 11, a first gas outlet 12 and a second gas outlet 13, the first gas inlet 11 is used to communicate with the left end of the inside of the airtight chamber 2, and the first gas outlet 12 is used for It communicates with the right end inside the airtight chamber 2, so that a closed and circulating loop is formed between the separation and removal unit 1 and the airtight chamber 2, that is, the air in the airtight chamber 2 enters the separation and removal unit 1 through the first air inlet port 11. Inside, and then return to the inside of the airtight warehouse 2 through the first air outlet 12, and the second air outlet 13 is used to communicate with the outside of the airtight warehouse 2;

[0048] The ...

Embodiment 2

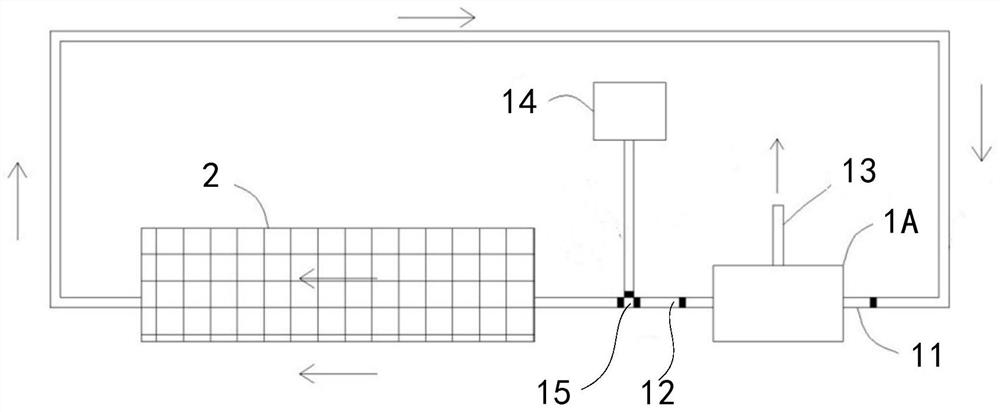

[0057] read on figure 2 The difference between the second embodiment and the first embodiment is that the adsorption separation assembly also includes a humidifier 14 and a three-way pipe 15, the outlet end of the humidifier 14 communicates with one of the mouths of the three-way pipe 15, and the three-way pipe 15 The other two nozzles of the tube communicate with the first gas outlet 12 and one end of the airtight chamber 1 respectively.

[0058] Preferably, the oxygen generator 1A is a low pressure adsorption vacuum desorption oxygen generator, the first suction part is a vacuum pump, and the molecular sieve is a zeolite molecular sieve.

[0059]During specific implementation, the oxygen generator 1A and the first suction part in the separation and removal unit 1 can be started simultaneously, and the humidifier 14 is opened to carry out synchronously. Other gases and the water vapor generated by the humidifier 14 flow back into the airtight chamber 2 together, and the air...

Embodiment 3

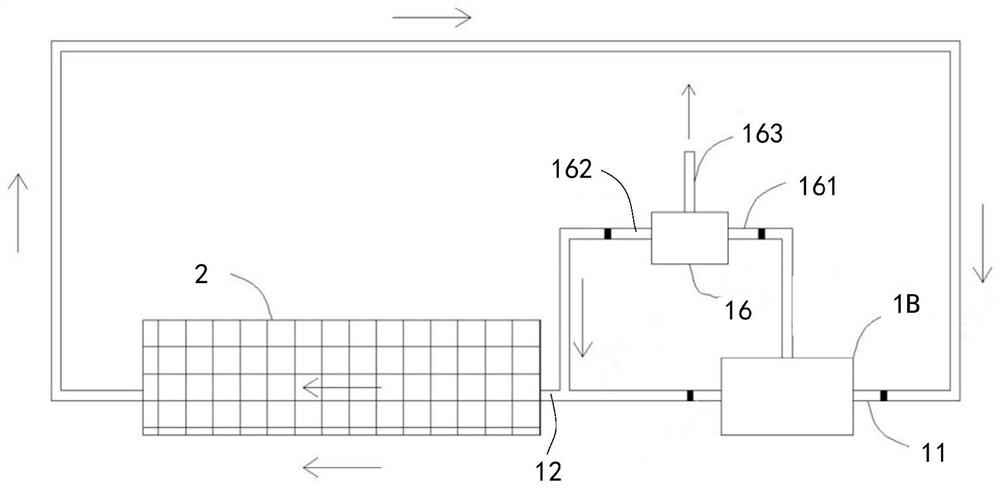

[0061] read on image 3 , The difference from Embodiment 1 and Embodiment 2 is that the adsorption separation assembly uses the deoxygenator 1B and the dehumidifier 16 to replace the oxygen generator 1A in Embodiment 1 and Embodiment 2.

[0062] Specifically, the deoxygenator 1B includes a first adsorption tower, the adsorbent assembly includes a first adsorbent, the first adsorbent is installed on the first adsorption tower, and a carbon molecular sieve is arranged on the first adsorbent to adsorb oxygen and the Water vapor in other gases except oxygen, and the nitrogen in the separated gases other than oxygen is discharged at the first gas outlet 12, and the first suction part is used to evacuate the first adsorption tower and vacuumize the first adsorption tower. An adsorption tower desorbs, so that oxygen and water vapor in gases other than oxygen are discharged to the dehumidifier 16 at the gas outlet of the deaerator 1B.

[0063] The dehumidifier 16 has a first air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com