Soup spoon groove stamping device

A technology of punching device and spoon, applied in the field of punching device, can solve the problems of low safety, manual feeding of spoons, manual feeding, etc., and achieve the effects of increasing safety, reducing wear and ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

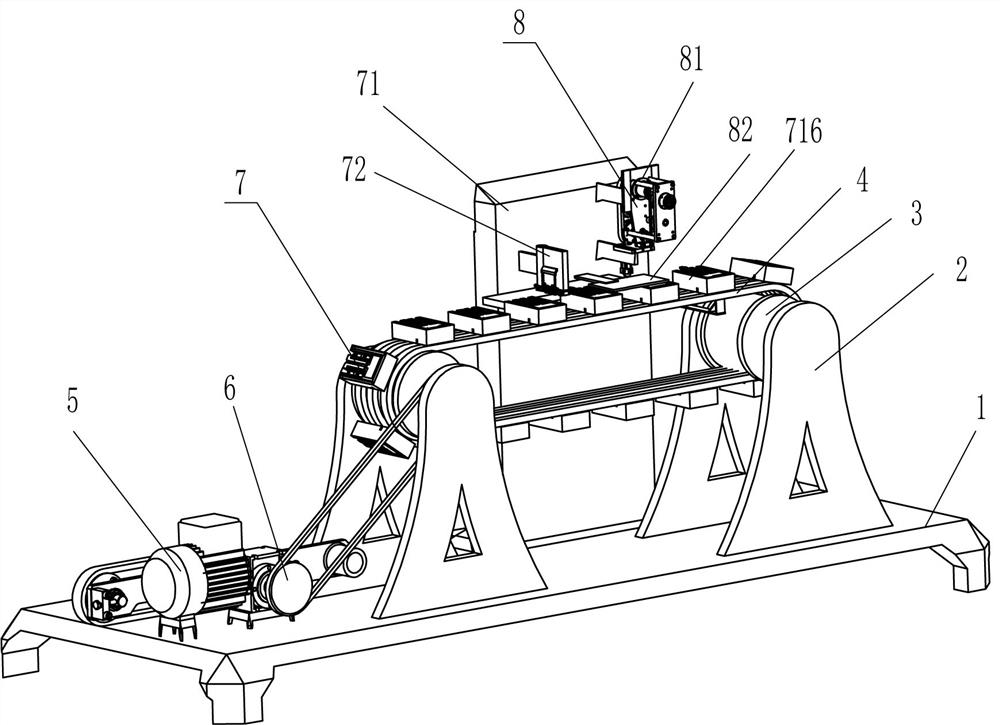

[0065] A spoon groove punching device such as figure 1 and Image 6 As shown, it includes a base 1, a support frame 2, a transmission cylinder 3, a conveyor belt 4, a motor 5, a transmission assembly 6, a blanking mechanism 7, a punching mechanism 8 and a pushing mechanism 9. The top of the base 1 is provided with Support frame 2, a transmission cylinder 3 is rotatably provided between the left support frame 2 and the right support frame 2, a conveyor belt 4 is provided between the outer sides of the transmission cylinder 3, and a motor 5 is provided on the left side of the top of the base 1 , a transmission assembly 6 is arranged between the output shaft of the motor 5 and the transmission cylinder 3 on the left side, a blanking mechanism 7 is arranged between the middle of the rear side of the top of the base 1 and the conveyor belt 4, and a punching mechanism 8 is arranged on the front side of the blanking mechanism 7, The punching mechanism 8 is above the conveyor belt 4 ...

Embodiment 2

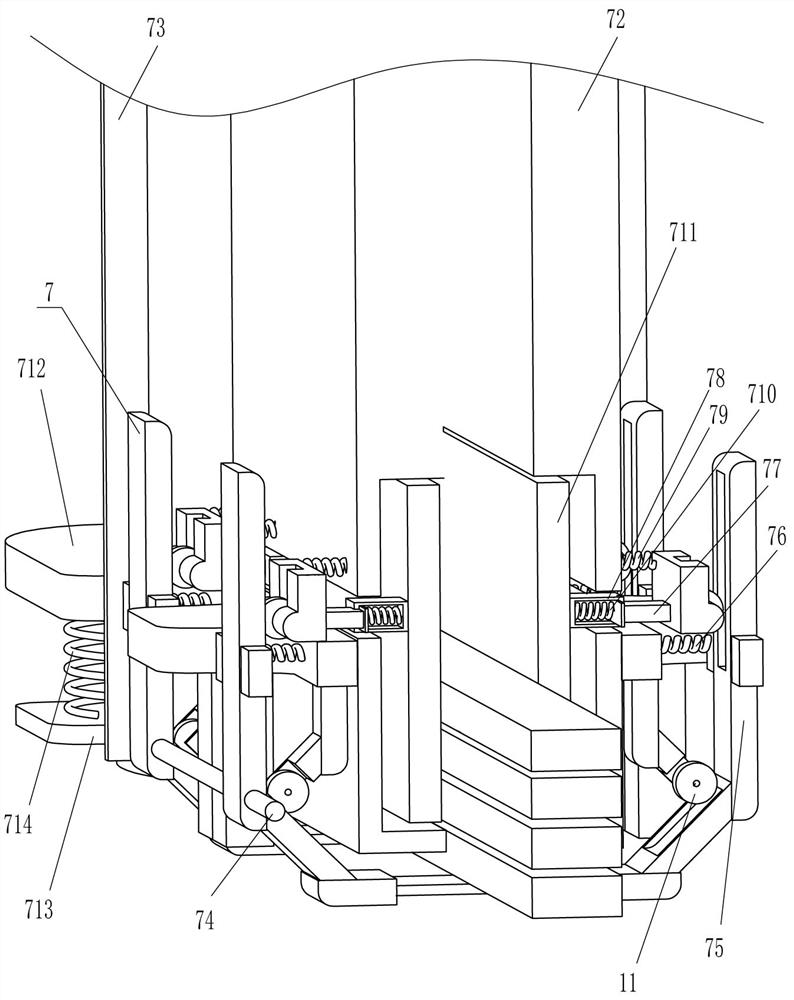

[0068] On the basis of Example 1, as figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the unloading mechanism 7 includes a rear side plate 71, a charging frame 72, a bracket 73, a rotating rod 74, an L-shaped blocking piece 75, a first spring 76, a push plate 77, a push block 78, and a second spring 79. Third spring 710, rubber splint 711, sliding plate 712, fixing plate 713, fourth spring 714, first magnet 715, material transport frame 716, sliding block 717, fifth spring 718 and second magnet 719, base 1 The rear side of the top is provided with a rear side plate 71, the front left of the rear side plate 71 is provided with a loading frame 72, the left and right sides of the loading frame 72 are symmetrically provided with fixed plates 713, and the top of the fixed plate 713 is provided with The fourth spring 714, a sliding plate 712 is arranged between the other end of the fourth spring 714, the inner side of the sliding plate 712 is slidably connecte...

Embodiment 3

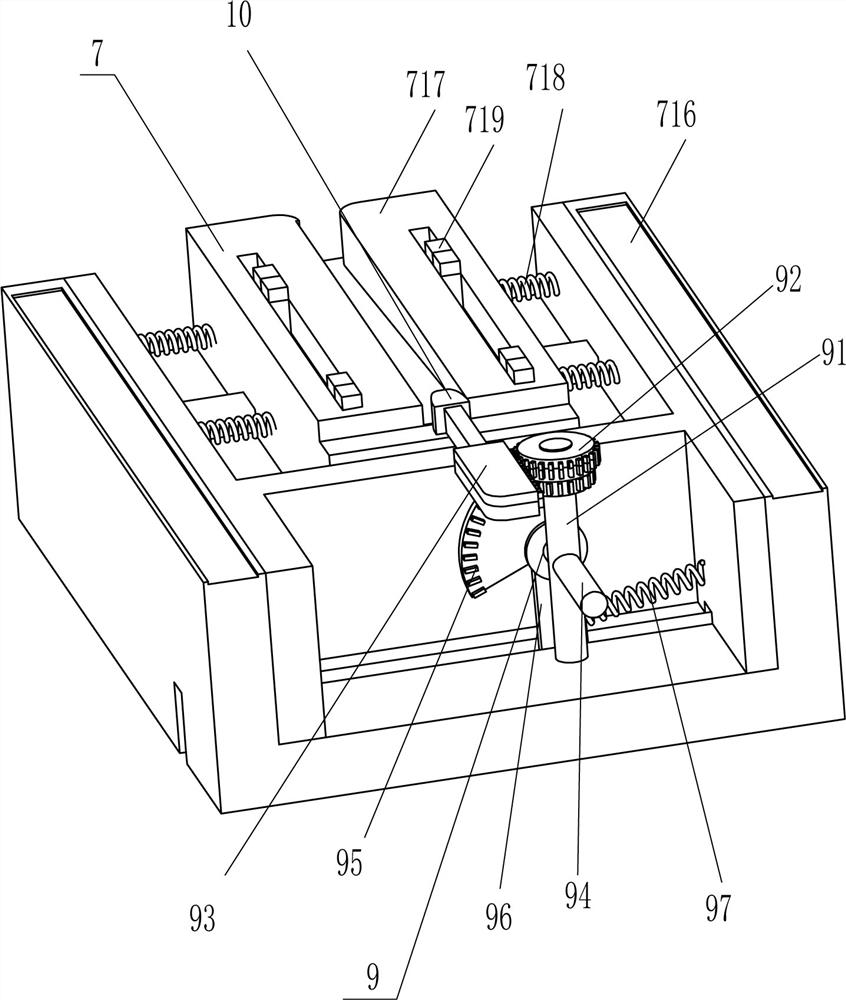

[0073] On the basis of Example 2, as Figure 5 and Image 6 As shown, the pushing mechanism 9 includes a first fixed rod 91, a double gear 92, a rack 93, a second fixed rod 94, a sector gear 95, a contact piece 96, a seventh spring 97 and a contact plate 98. The inner front part of the 716 is provided with a first fixing rod 91; There is a contact piece 96, the bottom of the contact piece 96 passes through the bottom of the material transport frame 716, the lower part of the contact piece 96 is in the slot opened at the bottom of the material transport frame 716, the top of the contact piece 96 is provided with a sector gear 95, the sector gear 95 and the double The lower side of the coupling gear 92 meshes with each other, and a seventh spring 97 is arranged between the lower right side of the contact piece 96 and the right side of the inner wall of the material transport frame 716. The top rear side of the material transport frame 716 is slidably provided with a rack 93. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com