Composite electric spindle

A technology of electric spindle and headstock, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of composite electric spindle restricting the application place of composite electric spindle, achieve simple structure, reduce axial length, The effect of simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

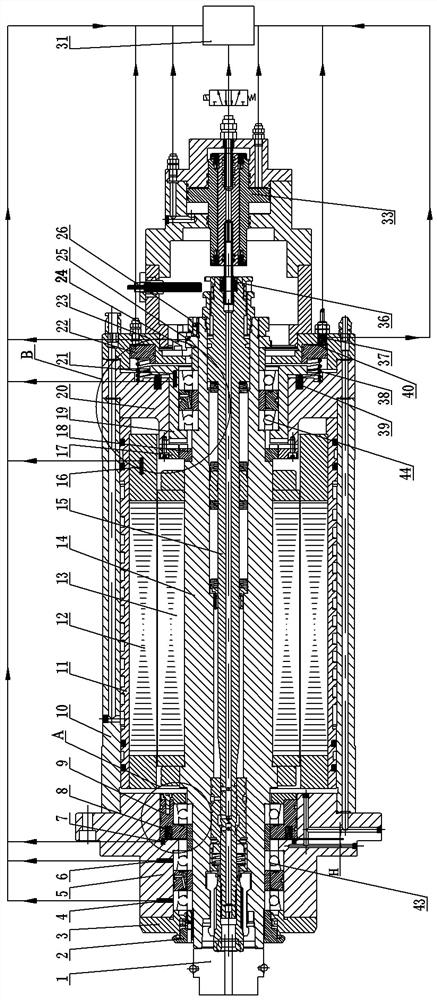

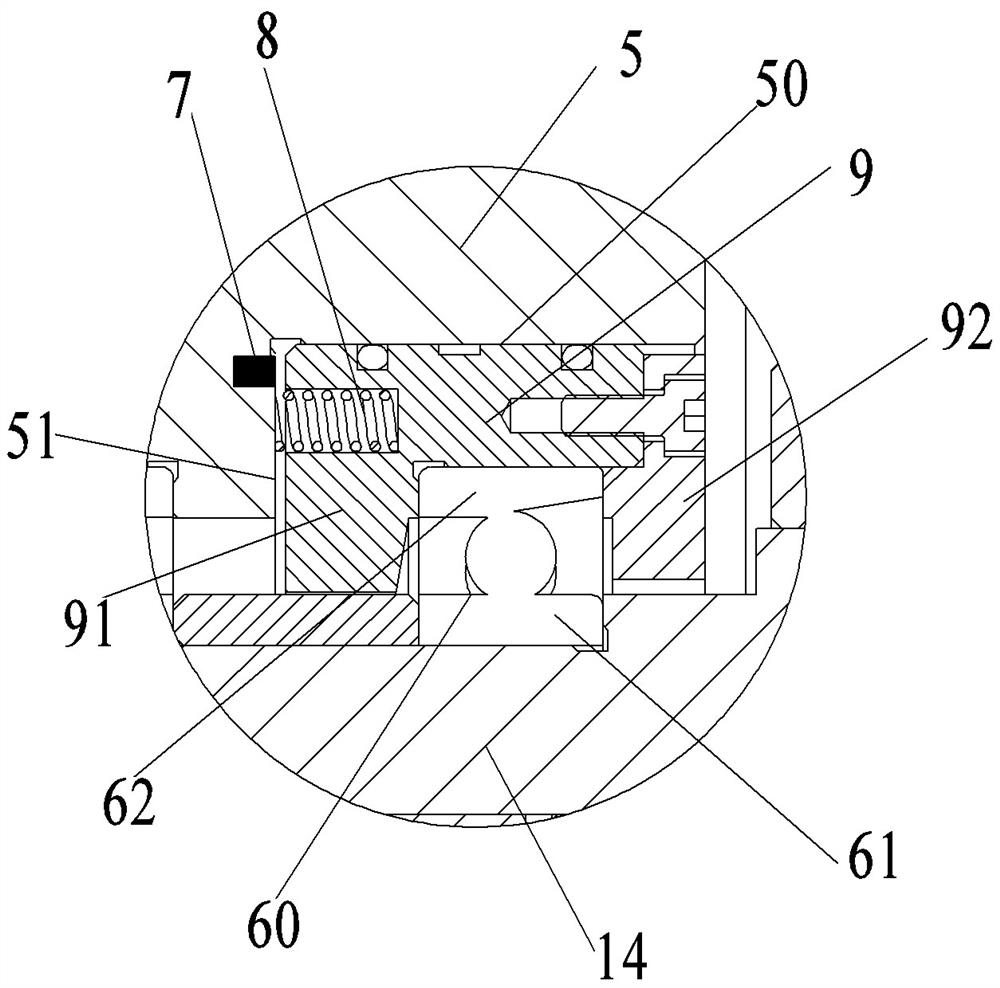

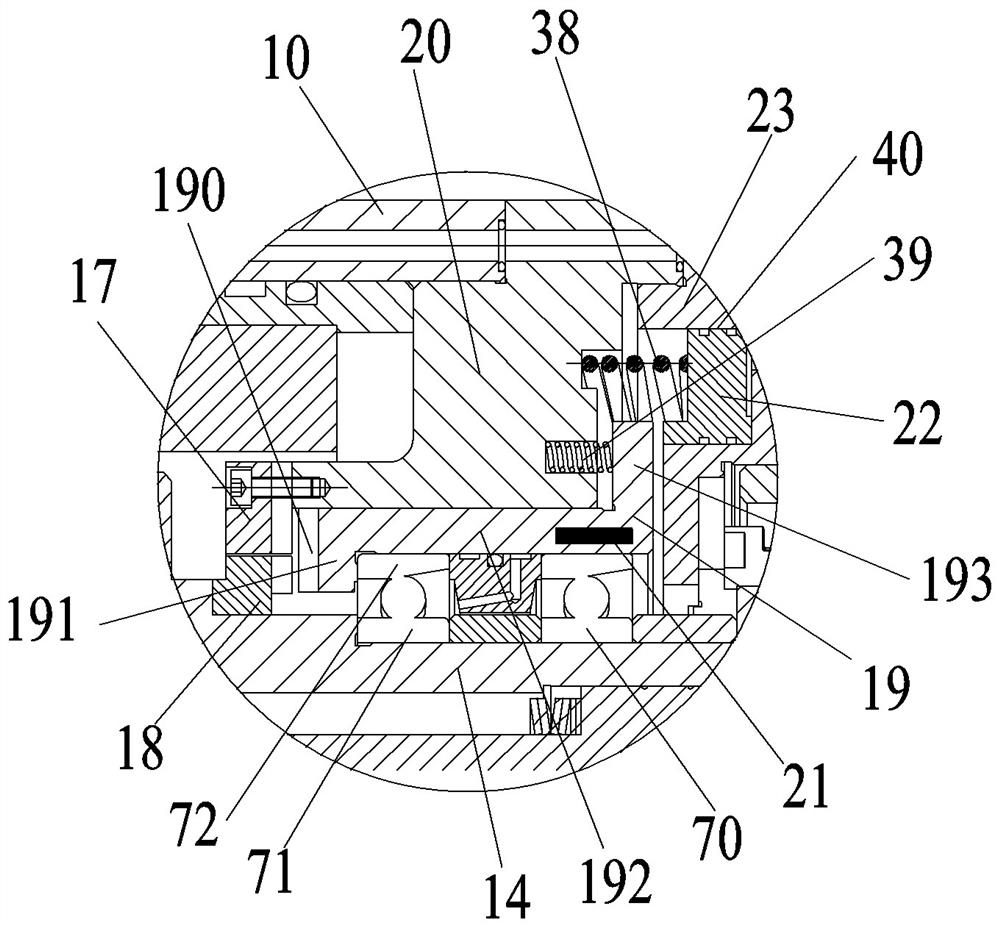

[0040] like Figure 1 to Figure 3 As shown, the composite electric spindle in this embodiment includes a headstock, and a motor and a rotating shaft 14 are arranged inside the headstock, and a front bearing support structure 43 and a rear bearing support structure 44 are arranged corresponding to the rotating shaft 14 to play the role of rotation support. The motor includes a motor stator 12 and a motor rotor 13. The motor stator 12 and the motor rotor 13 are located between the front bearing support structure 43 and the rear bearing support structure 44 to act as a power source. The motor rotor 13 is fixedly assembled with the rotating shaft 14, and the rotating shaft The center of 14 is provided with a broach system 15 and a rotary joint connecting rod 36 to play the role of rapid tool change and central cooling. The front end of the rotary joint pull rod 36 is connected to the broach system 15, and the rear end is connected to the driving piston 33 for releasing the knife. ...

specific Embodiment 2

[0069] The main difference between it and Embodiment 1 is that in Embodiment 1, the front end of the rear bearing seat is integrated with the floating toothed disc. On the basis of the integrated arrangement of the floating toothed disc and the rear bearing seat, in this embodiment, the floating The body is fixedly installed on the front end of the rear bearing seat, and can be fixed and installed by screws.

specific Embodiment 3

[0071] It differs from Embodiment 1 mainly in that: in Embodiment 1, the three toothed disc mechanism is located at the rear side of the motor rotor, and the floating toothed disc is integrated and arranged on the rear bearing seat, and is arranged on the rear side to reduce the front end of the composite electric spindle. For the purpose of radial dimension, in this embodiment, the floating chainring of the three-sprocket mechanism is completely separated from the rear bearing seat, the rear bearing support structure is arranged in front, and the three-sprocket mechanism is located at the rear side of the rear bearing support structure. The movable toothed plate with large radial size is assembled with the rotating shaft. The floating toothed plate can be guided and moved along the front and rear direction and assembled on the rear end cover. The fixed toothed plate is clamped and fixed between the rear inner cover and the rear end cover. By locking the top of the piston Pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com