Novel semiconductor silicon wafer circle-cutting equipment

A semiconductor and silicon wafer technology, applied in the field of new semiconductor silicon wafer cutting equipment, can solve the problems of circular silicon wafer scratches, easy edges, silicon wafer burrs, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 To attach Figure 6 Shown:

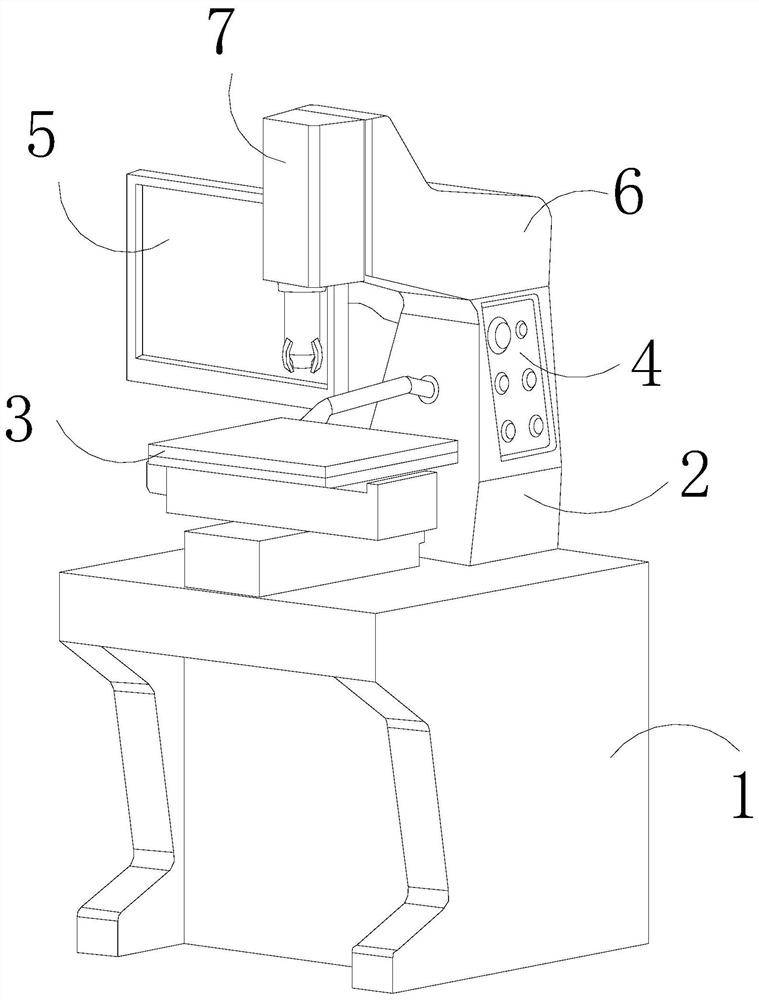

[0030] The invention provides a new type of semi-conductor silicon wafer cutting equipment, the structure of which includes a machine base 1, a control table 2, a working surface 3, a control panel 4, a system display screen 5, a rotating head 6, and a cutting head 7. The control table 2 Welded on the rear side of the top surface of the machine base 1, the worktable 3 is located in front of the control console 2, the control panel 4 and the control console 2 are integrated structures and are arranged on one side of the control console 2, the system The display screen 5 is fixedly connected to the other side of the control table 2 , the rotating head 6 is movably connected to the top of the control table 2 , and the cutting head 7 is connected to the front end of the rotating head 6 .

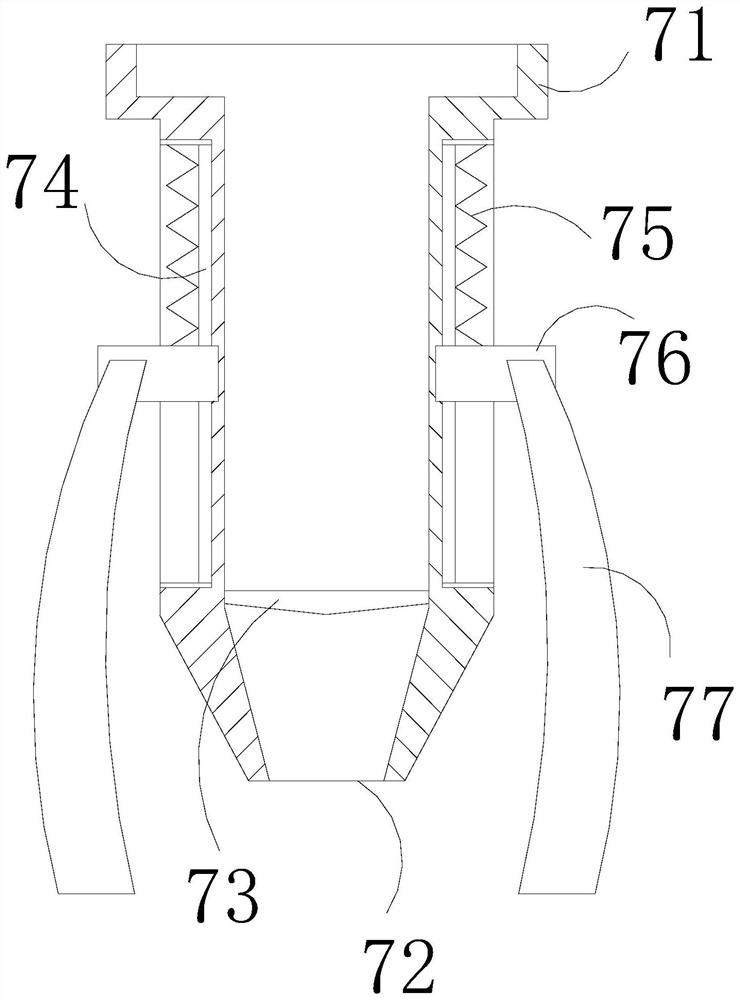

[0031] The cutting head 7 is provided with a columnar frame 71, a beam penetrating head 72, a focusing mirror 73, a guide rail 74, a sp...

Embodiment 2

[0037] as attached Figure 7 To attach Figure 8 Shown:

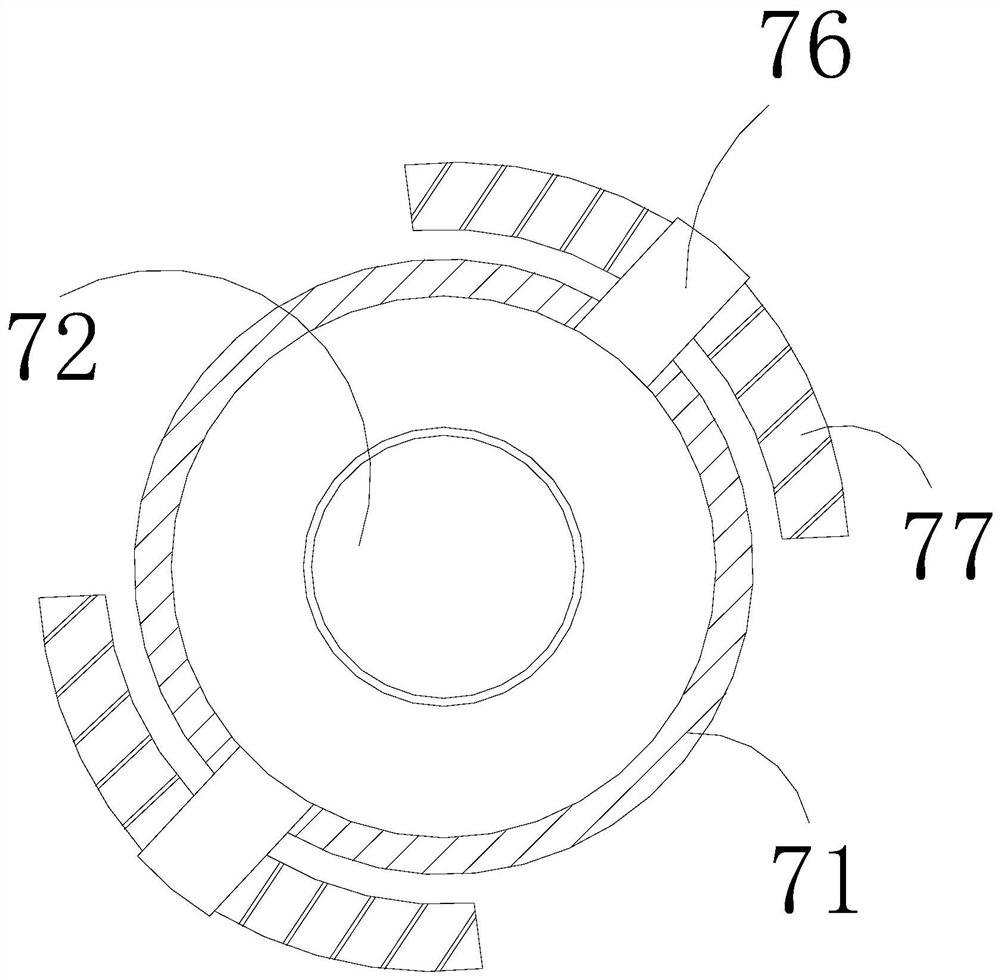

[0038] Wherein, the arc cavity 771 is provided with a movable chamber 71a, a first airbag 71b, a second airbag 71c, and an air intake drum 71d, and the movable chamber 71a is arranged between the first airbag 71b and the second airbag 71c, The intake drum 71d is at the upper end of the movable chamber 71a, the intake drum 71d is connected through the first air bag 71b and the second air bag 71c, and there is gas inside the first air bag 71b and the second air bag 71c. The air intake drum 71d is made of high-elastic rubber material, and the slow pressure wheel 772 slides inward along the inner side wall, squeezing the first air bag 71b and the second air bag 71c, so that the gas goes up, and the air intake drum 71d 71d is used as an elastic hollow ball to accommodate gas.

[0039] Wherein, the pulling cavity 773 is provided with a concave cavity 73a, an arc rail 73b, a push rod 73c, a roller 73d, and a rear pulling en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap