Slender shaft auxiliary machining equipment for numerically controlled lathe

A technology of CNC lathes and auxiliary equipment, which is applied in the direction of metal processing equipment, turning equipment, auxiliary equipment, etc., can solve problems such as processing errors of slender shafts, and achieve the effects of avoiding processing errors, good use effects, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

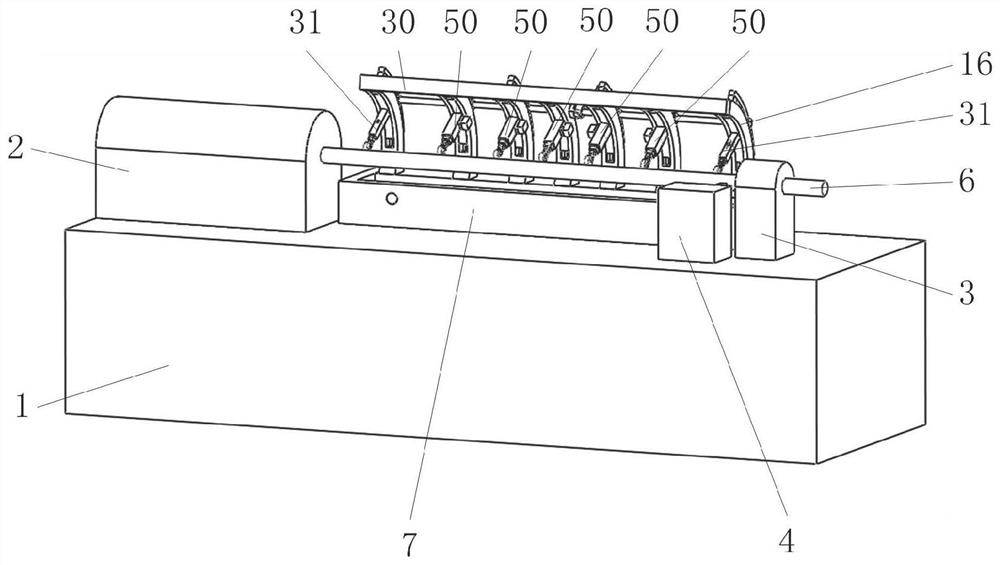

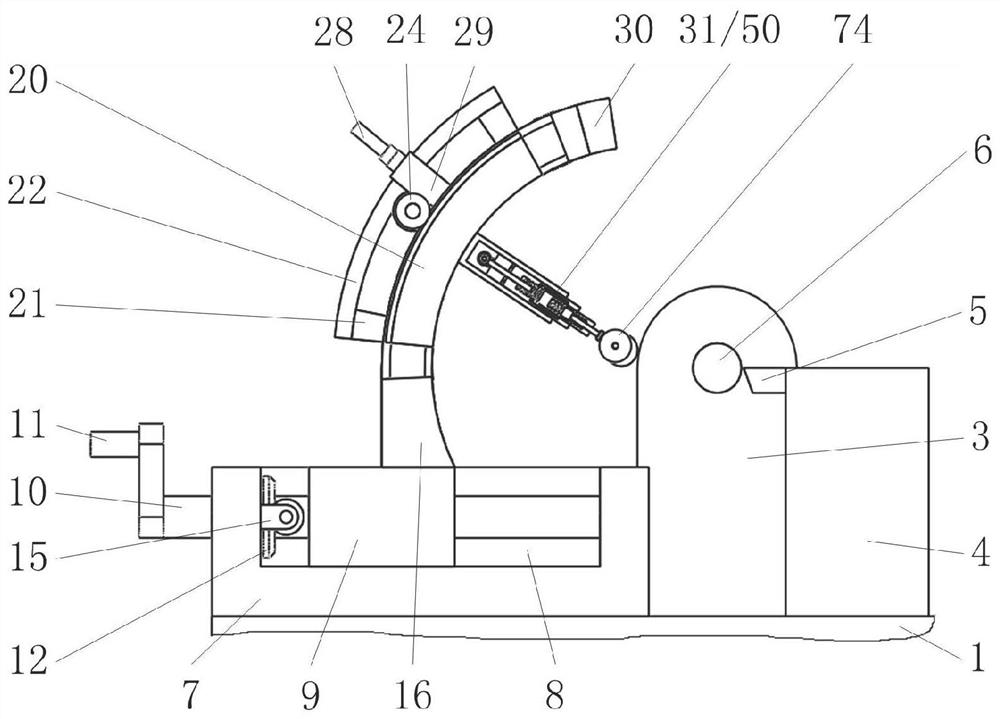

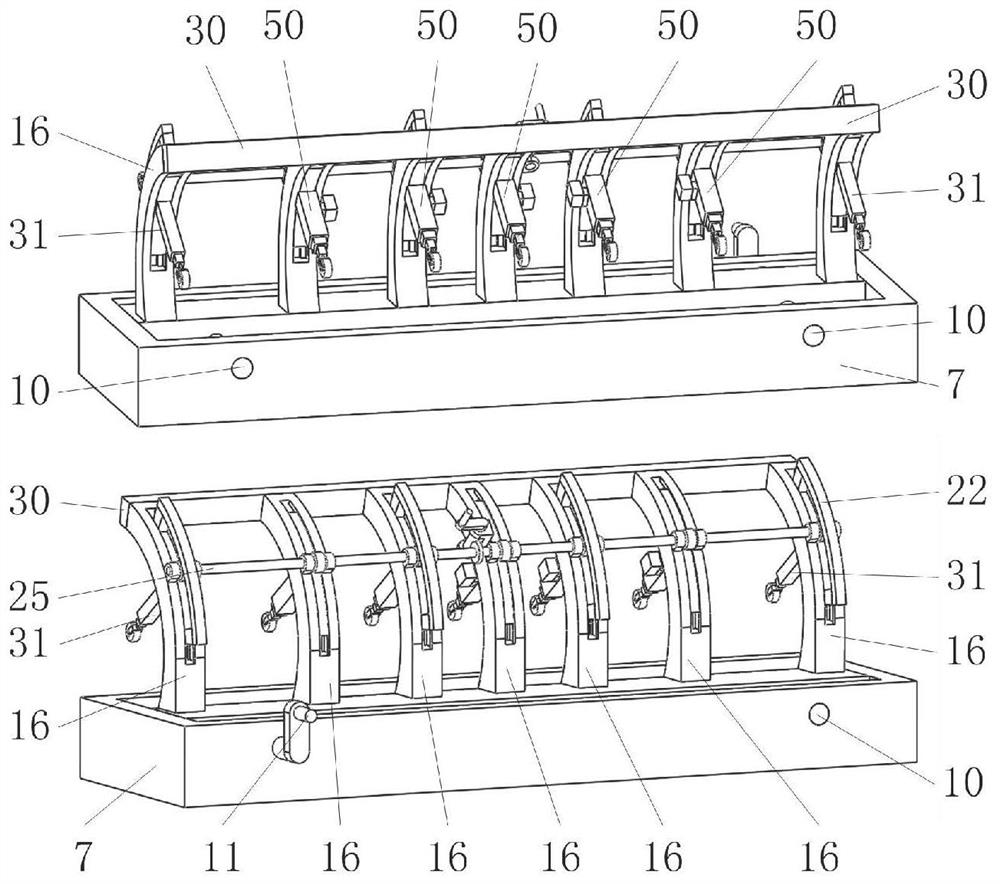

[0037] Such as image 3 As shown, it includes a base 7, a sliding seat 9, a screw rod A10, an arc bracket 16, a bearing B19, a T-shaped guide block 20, a shaft B25, a telescopic rod mechanism A31, and a telescopic rod mechanism B50. figure 1 , 2 , 7, the base 7 is installed on the bed of the machine tool, and the chute A8 on the base 7 slides in the direction perpendicular to the slender shaft 6 with a sliding seat 9, and the two screw rods A10 that are rotatably matched with the base 7 and the sliding seat 9 Thread fit, constant speed transmission connection between two screw rods A10; figure 1 , 3 As shown, a number of arc-shaped brackets 16 distributed along the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com