Polyimide film curing oven capable of accurately controlling temperature

A polyimide film, precise technology, applied in the field of polyimide film curing and precise temperature control oven, can solve the problems of energy consumption loss of heating and cooling, temperature adjustment of the film surface, slow temperature change speed, etc., and achieve reasonable structural design , Improve drying efficiency, reduce the effect of heating and cooling energy consumption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

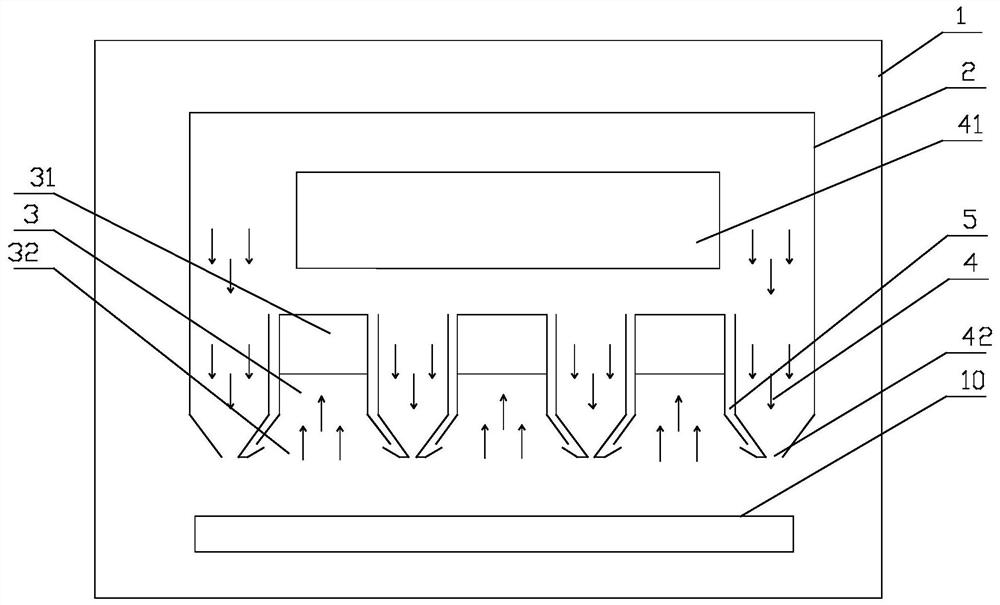

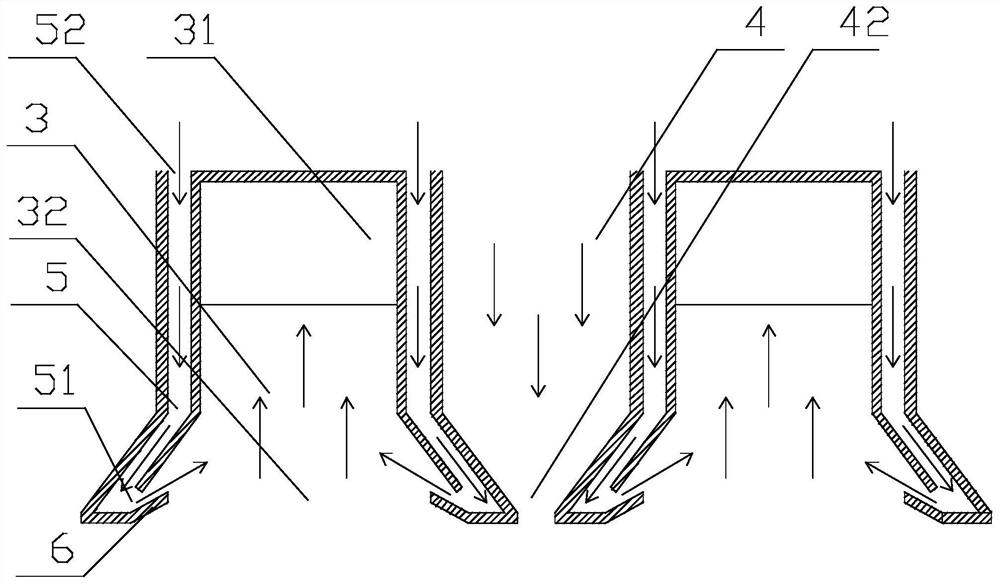

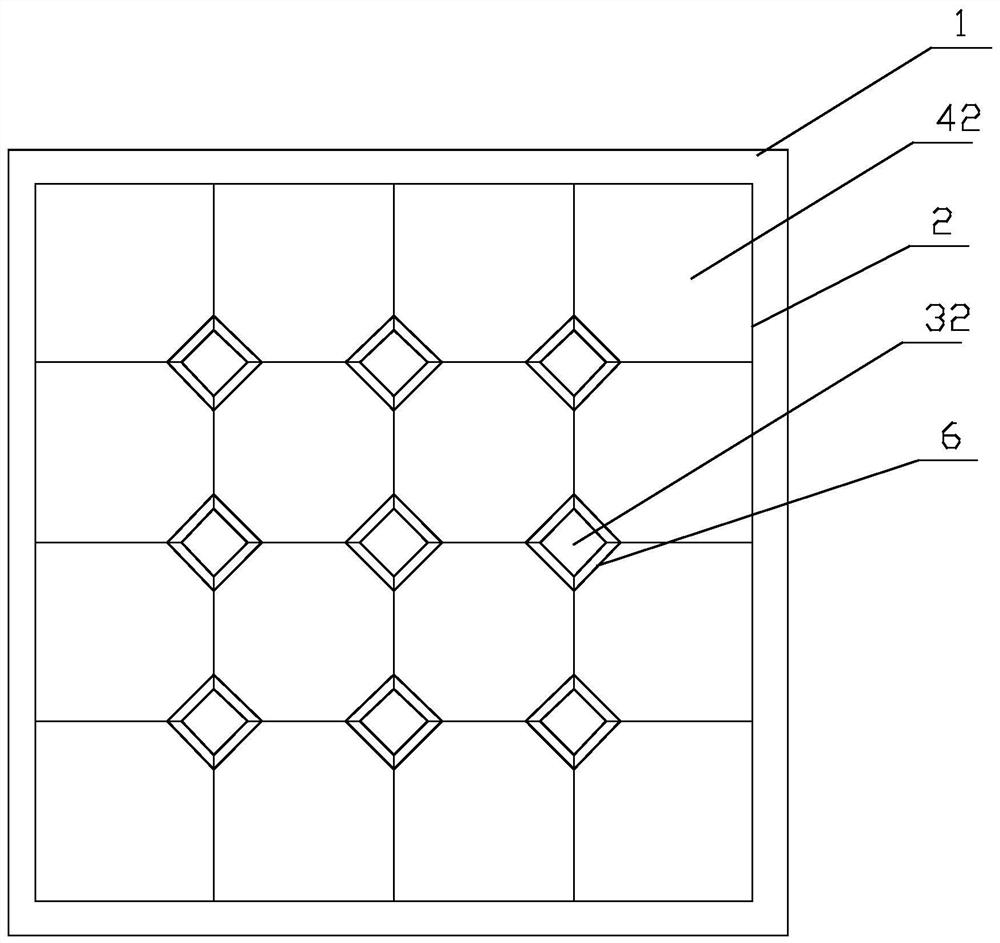

[0022] Such as Figures 1 to 5 as shown, figure 1 It is a structural schematic diagram of a polyimide film solidification and precise temperature control oven proposed by the present invention, figure 2 It is a schematic diagram of the local air flow of the air supply mechanism of a polyimide film solidified and precisely temperature-controlled oven proposed by the present invention, image 3 It is a schematic diagram of the distribution of the air outlet and the suction inlet of a polyimide film solidified and precisely temperature-controlled oven proposed by the present invention, Figure 4 It is a schematic diagram of the partial structure of the cooperation of the air suction cylinder and the heat insulation cylinder of a kind of polyimide film curing and precise temperature control oven proposed by the present invention, Figure 5 It is a structural schematic diagram of another embodiment of an oven with precise temperature control for polyimide film curing proposed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com