Preparation method of space cloth material

A space and film technology, applied in the direction of chemical instruments and methods, flat products, applications, etc., can solve the problem of substandard peel strength and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

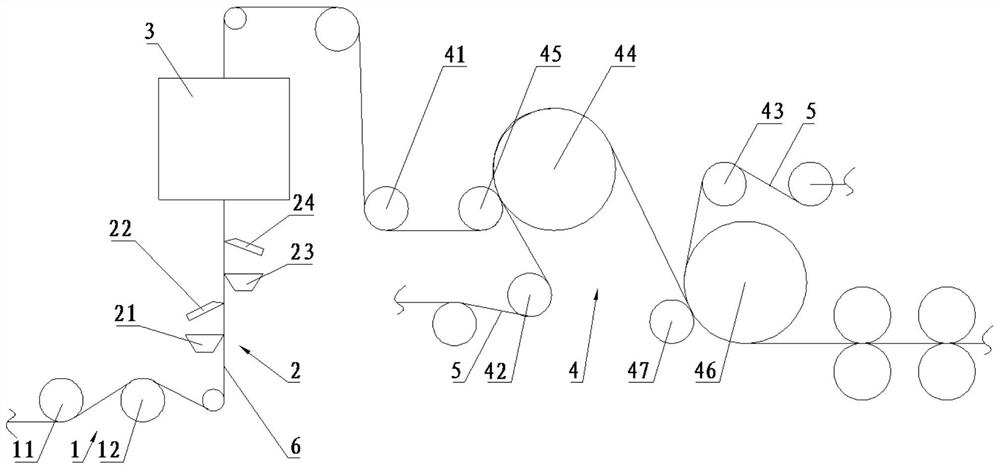

[0018] The present invention provides a kind of preparation method of space cloth material, comprises the following steps:

[0019] Step 1, the upper surface and the lower surface of the PE space cloth are ironed respectively, and the upper surface and the lower surface of the PE space cloth after the ironing process are coated with PU paste at the same time, and then dried to obtain the pasted PE space cloth;

[0020] Wherein, the paste amount of the PU paste is 50-80gsm, and the viscosity of the PU paste is 40000-60000cps;

[0021] Step 2. The pasted PE space cloth and the film are preheated respectively, and then the film is placed on both sides of the pasted PE space cloth, and hot-pressed to obtain the space cloth material;

[0022] The PE space cloth includes an upper base cloth, a lower base cloth and a wire drawing structure arranged between the upper base cloth and the lower base cloth.

[0023] The upper surface of the PE space cloth is the upper bottom surface of t...

Embodiment 1

[0039] A preparation method of a space cloth material, specifically comprising the following steps:

[0040] Step 1. The upper surface and the lower surface of the PE space cloth are respectively ironed at 100°C, and the upper surface and the lower surface of the PE space cloth after the ironing treatment are coated with PU paste at the same time, and then dried at 120°C to obtain Paste PE space cloth;

[0041] Wherein, the amount of paste on one side of the PU paste is 60gsm, and the viscosity of the PU paste is 40000cps;

[0042] Step 2. Preheat the pasted PE space cloth and the TPU film respectively, and then place the TPU film on both sides of the pasted PE space cloth at 40kg / cm 2 , 150°C for hot-press lamination to obtain the space cloth material;

[0043] Among them, the preheating temperature of the upper surface and the lower surface of the PE space cloth is 100°C, and the preheating temperature of the TPU film is 120°C.

Embodiment 2

[0045] A space cloth material, prepared by the following preparation method of the space cloth material, the preparation method of the space cloth material specifically includes the following steps:

[0046] Step 1. The upper surface and the lower surface of the PE space cloth are respectively ironed at 90°C, and the upper surface and the lower surface of the PE space cloth after the ironing treatment are coated with PU paste at the same time, and then dried at 100°C to obtain Paste PE space cloth;

[0047]Wherein, the pasting amount of the PU paste is 50gsm, and the viscosity of the PU paste is 60000cps;

[0048] Step 2. Preheat the pasted PE space cloth and the PVC film respectively, and then place the PVC film on both sides of the pasted PE space cloth at a temperature of 30kg / cm 2 , 170 ° C under hot pressing lamination, to obtain the space cloth material;

[0049] Among them, the preheating temperature of the upper and lower surfaces of the PE space cloth is 105°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com