A heavy metal mesoporous adsorption material based on molybdenum ore tailings as raw material and its preparation method and application

An adsorption material and heavy metal technology, which is applied in the field of environmental heavy metal pollution treatment, can solve problems such as land occupation, waste of resources, and environmental pollution risks, and achieve the effects of improving quality, good adsorption effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Preparation of heavy metal mesoporous adsorption material based on molybdenum ore tailings as raw material

[0043] (1) Take 15g of molybdenum ore tailings and grind through a 200 mesh sieve, add 30ml, 1mol / L H 2 SO 4 Vibrate in a shaker, filter and separate, and dry; divide into crucibles, add an equal mass of NaOH to each crucible, and heat them together in a muffle furnace at 823K. After 3 hours, take them out to cool naturally, and grind them for use.

[0044] (2) Take 5g of the product that was ground in step (1) and add 90ml of deionized water to dissolve it, centrifugally filter the supernatant, transfer it to a teflon tank, and add 5.4g of sodium metaaluminate and 15.75g of water glass to adjust the material Ratio, magnetically stirred at 343K for 1h.

[0045] (3) Transfer the stirred reaction materials in the teflon tank to the reactor, and react at 373K. After 8 hours of reaction, take it out and cool to room temperature, filter, wash, and dry to ...

Embodiment 2

[0047] at 0.05mol L -1NaCl solution was used as the supporting electrolyte solution, and the concentration of Cd solution was prepared to be 100mg L -1 solution of heavy metal ions. Measure 25mL of the metal ion solution with the above concentration, add it into a 50mL centrifuge tube filled with 0.1g of the heavy metal adsorption material prepared in Example 1, repeat each treatment 3 times, and take the average value. Cover the centrifuge tube with the sample added, and set the temperature at 250r·min -1 , (25±2)°C, shake for 24h, then rotate at 6000r·min -1 Centrifuge for 30 min, filter, and measure the concentration of Cd ions in the equilibrium solution by atomic absorption spectrophotometry (AAS).

[0048] The results of the adsorption material made with sodium hydroxide showed that the Cd concentration of the supernatant after the equilibrium measurement was 0.25mg L -1 , that is, the processing rate can reach 99.76%.

Embodiment 3

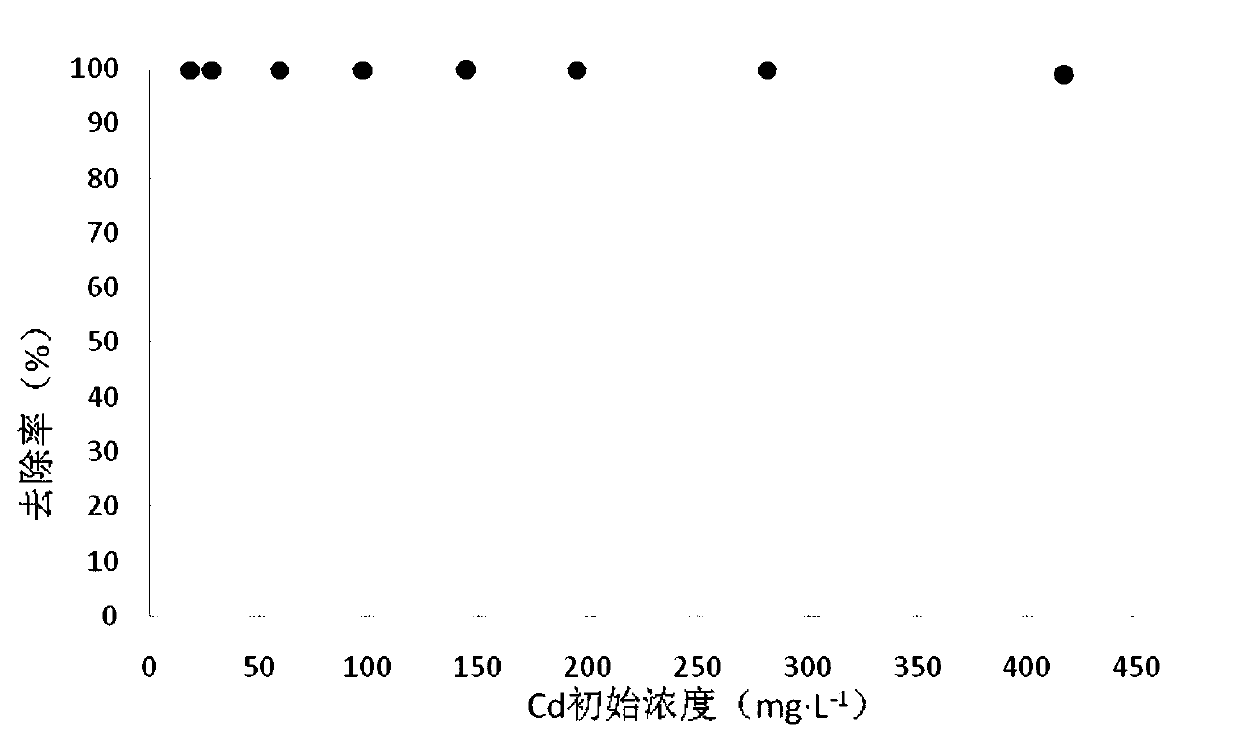

[0050] at 0.05mol L -1 NaCl solution is used as the supporting electrolyte solution, and the metal ion solutions of the following concentrations are prepared respectively, and the concentration of Cd solution: 20, 30, 60, 100, 140, 190, 280, 420mg L -1 Measure the metal ion solution of 25mL above-mentioned concentration, add in the 50mL centrifuge tube that fills the heavy metal adsorption material that 0.1g embodiment 1 prepares, each treatment repeats 3 times, gets the average value. Cover the centrifuge tube with the sample added, and set the temperature at 250r·min -1 , (25±2)°C, shake for 24h, then rotate at 6000r·min -1 Centrifuge for 30 min, filter, and measure the concentration of Cd ions in the solution after equilibrium with atomic absorption spectrophotometry (AAS), so as to obtain the removal rate.

[0051] The heavy metal adsorption material prepared in embodiment 1 is to the removal rate figure of Cd in the Cd-containing solution under different concentrations:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com