Processing method for improving vacuum freeze-drying rate of dried shrimps

A technology of vacuum freeze-drying and processing method, applied in meat/fish preservation, food preservation, food science and other directions, can solve problems such as unfavorable industrial production, reduced edible safety, low drying rate, etc., to improve edible safety, The effect of shortening drying time and enhancing drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

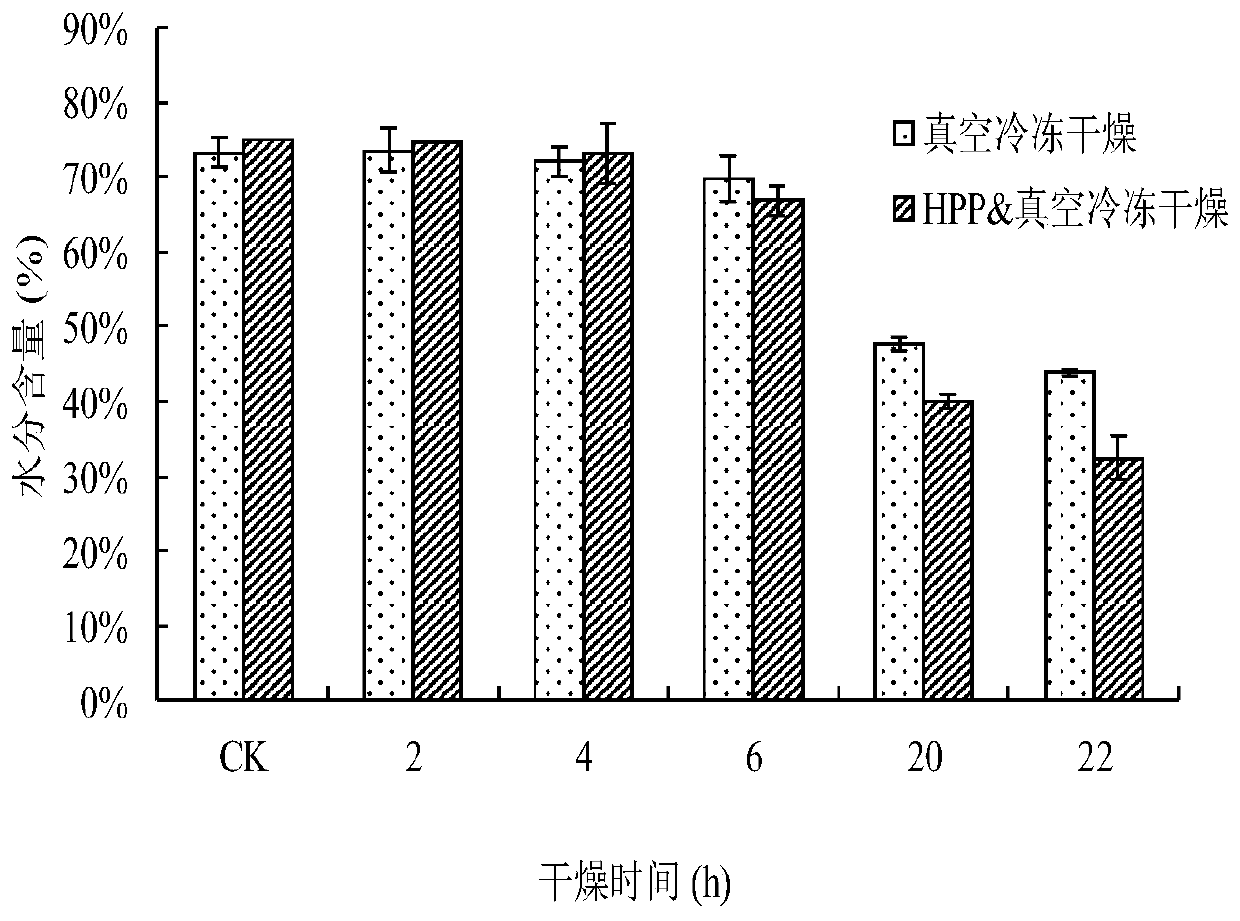

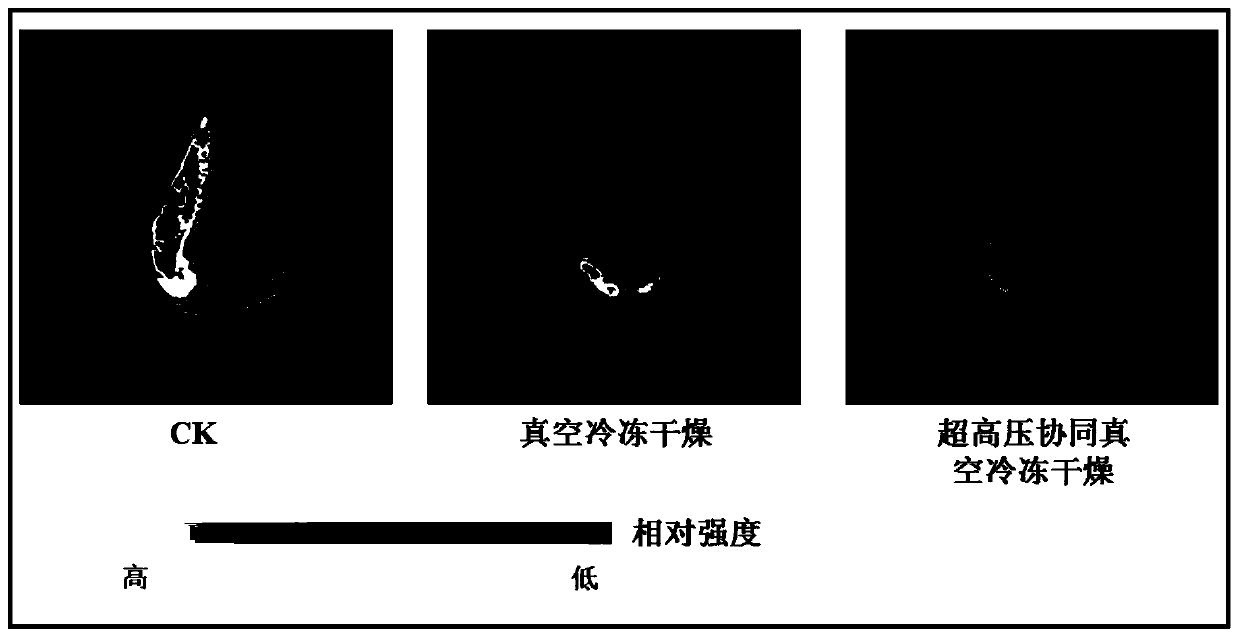

[0033] A processing method for improving the vacuum freeze-drying rate of dried shrimps, comprising the following steps:

[0034] ① Select fresh prawns with uniform size and no mechanical damage, wash them with tap water and pack them for later use;

[0035] ②Ultra-high pressure pretreatment of the packaged prawns;

[0036] ③ Put the pretreated prawns in Pre-freeze for 3 hours under the same conditions;

[0037] ④ Vacuum freeze-drying the pre-frozen prawns to obtain dried shrimps.

[0038] In this embodiment, the raw material of prawns is Penaeus vannamei.

[0039] In step ②, the treatment pressure of ultra-high pressure pretreatment is 300MPa, the treatment time is 15min, and the treatment temperature is 10°C.

[0040] Tap water is used as the pressure transmission medium for ultra-high pressure pretreatment in step ②, and the temperature of the pressure transmission medium is controlled at 10°C.

[0041] The loading capacity of vacuum freeze-dried prawns in step ④ is 1...

Embodiment 2

[0043] Compared with Example 1, the difference is that in this example, the treatment pressure of the ultra-high pressure pretreatment in step ② is 400MPa, the treatment time is 10min, and the treatment temperature is 20°C; the pressure transmission medium of the ultra-high pressure pretreatment in step ② adopts Weakly acidic potential water, the temperature of the pressure transmission medium is controlled at 20°C; weakly acidic potential water is prepared as follows: electrolyze the mixed solution containing 0.04% HCl and 0.15% NaCl by mass percent for 5 minutes; The loading capacity of prawns is 2kg, the drying temperature is 55°C, the vacuum degree is <10Pa, and the treatment time is 20 hours.

Embodiment 3

[0045] Compared with Example 2, the difference is that in this example, weakly acidic potential water is prepared as follows: electrolyzing a mixed solution containing 0.1% by mass percent HCl and 0.25% by mass percent NaCl for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com