Semitrailer fence structure and manufacturing method

A technology of a semi-trailer and a manufacturing method, which is applied to the superstructure, superstructure, manufacturing tools and other directions of a truck, can solve the problems of uneven welding amount, influence on structural strength, interference friction, etc. Production line production, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further details and effects of the invention are explained in more detail below by means of different illustrative embodiments shown in the drawings. The embodiments described by referring to the figures are exemplary for the purpose of explaining the present invention and should not be construed as limiting the present invention.

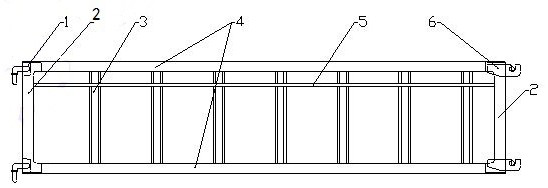

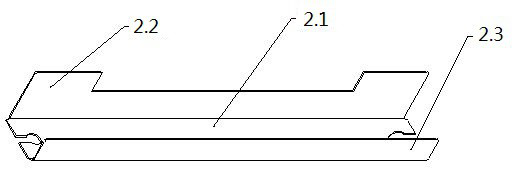

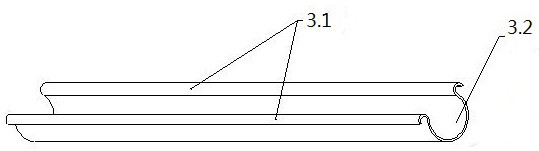

[0019] Barrier structure embodiment of the present invention, see figure 2 , 3 , a fence structure for a semi-trailer, comprising a vertical piece (2), a horizontal piece (4), a middle vertical piece (3), the two ends of the vertical piece (2) and the horizontal piece (4) Plug-in connection, the lateral piece (4) is fixedly connected with the middle vertical piece (3). After the two ends of the vertical side member (2) are plugged and connected to the horizontal side member (4), the amount of melting welding is small, which reduces deformation, and the box-shaped plug-in structure increases the strength. The vertical side piece (2) is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com