Cavitator with adjustable annular-conical gap

A ring-cone and cavitator technology, which is applied in the field of cavitators, can solve problems such as failure to meet environmental protection requirements, sludge pollution, and high cost of sludge treatment, and achieve good processing technology and assembly technology, and improve air quality. Efficiency, free disassembly and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

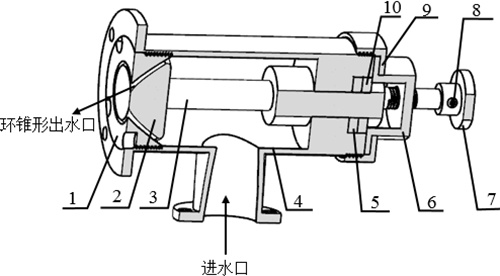

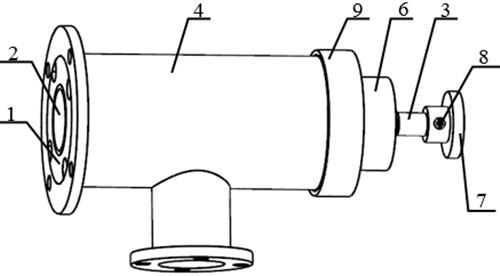

[0019] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] combine figure 1 and figure 2 , an annular conical cavity consisting of an inner frustoconical element (1) and an outer frustoconical element (2), a left annular conical water outlet, a shaft body (3), a lower water inlet, a housing (4 ), sealing ring (5), end cover (6), regulating valve (7), screw (8), connection and fixing element (9), sealing ring (10).

[0021] The inner truncated conical element (1) and the shell (4) are tightly fitted through threads, and a gasket can be clamped between the right end surface of the inner truncated conical element (1) and the shell (4) to ensure its sealing The outer section of the inner frusto-conical element (1) is drilled with four grooves and installed manually.

[0022] The outer frusto-conical element (2) is threadedly connected to the shaft body (3), the purpose i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com