Device and method for synchronous catalytic oxidation and decoloration of coking desulfurization waste liquid

A coking desulfurization waste liquid, catalytic oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, gaseous effluent wastewater treatment, etc., can solve the problem of reducing secondary salt recovery rate, low steam utilization rate, and demanding equipment materials and other problems, to achieve the effect of saving construction cost and operating cost, reducing the area occupied by the device, and improving the heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

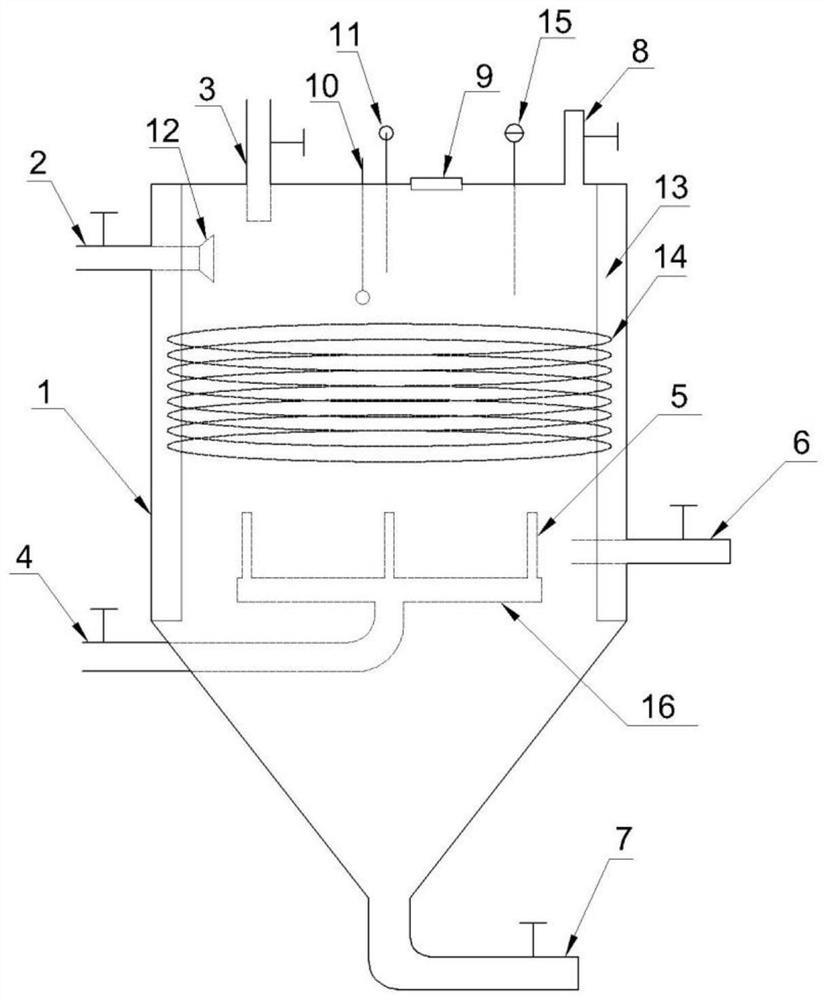

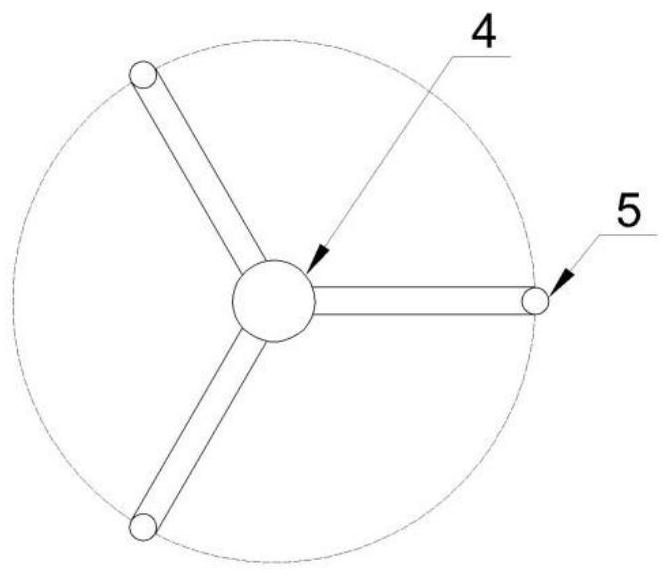

[0025] Such as figure 1 , figure 2 As shown, a device for synchronous catalytic oxidation and decolorization of coking desulfurization waste liquid, including a device housing 1, the upper part of the device housing 1 is a columnar area, and the lower part is a cone-shaped area. The columnar area is a jacketed structure, clamping A heating spiral tube 14 is provided in the heating chamber 13 of a jacket structure, a compressed air injection pipeline is provided at the lower part of the columnar area, and a desulfurization waste liquid inlet 2, a catalyst feeding port 3, and an exhaust gas injection port are provided at the upper part of the device shell 1. An outlet 8, a desulfurization waste liquid outlet 6 is provided on the device housing 1 below the heating coil 14, and a solid discharge outlet 7 is provided at the bottom of the tapered area.

[0026] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com