Anoxic tank gas stirring device for sewage treatment and stirring method

A technology of sewage treatment and air agitation, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc. It can solve the problems of insufficient mixing of sludge and water, excessive dissolved oxygen in anoxic pools, Unsatisfactory treatment effect and other problems, to achieve the effect of solving the dissolved oxygen exceeding the standard, good stirring effect, and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

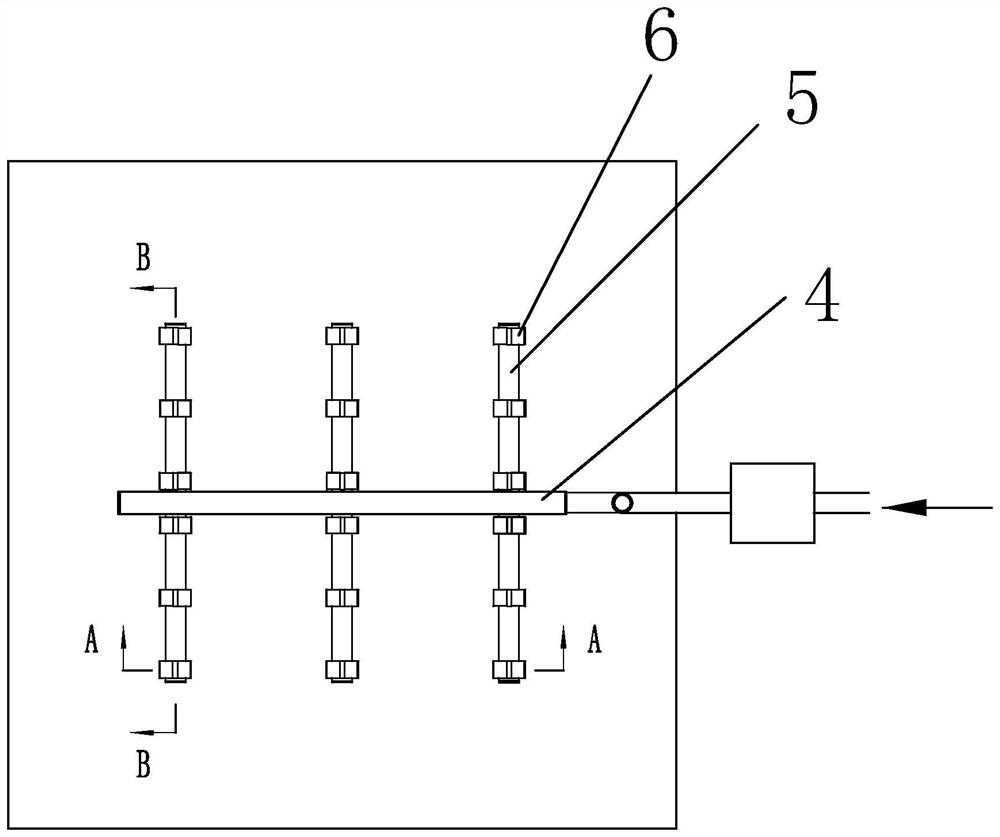

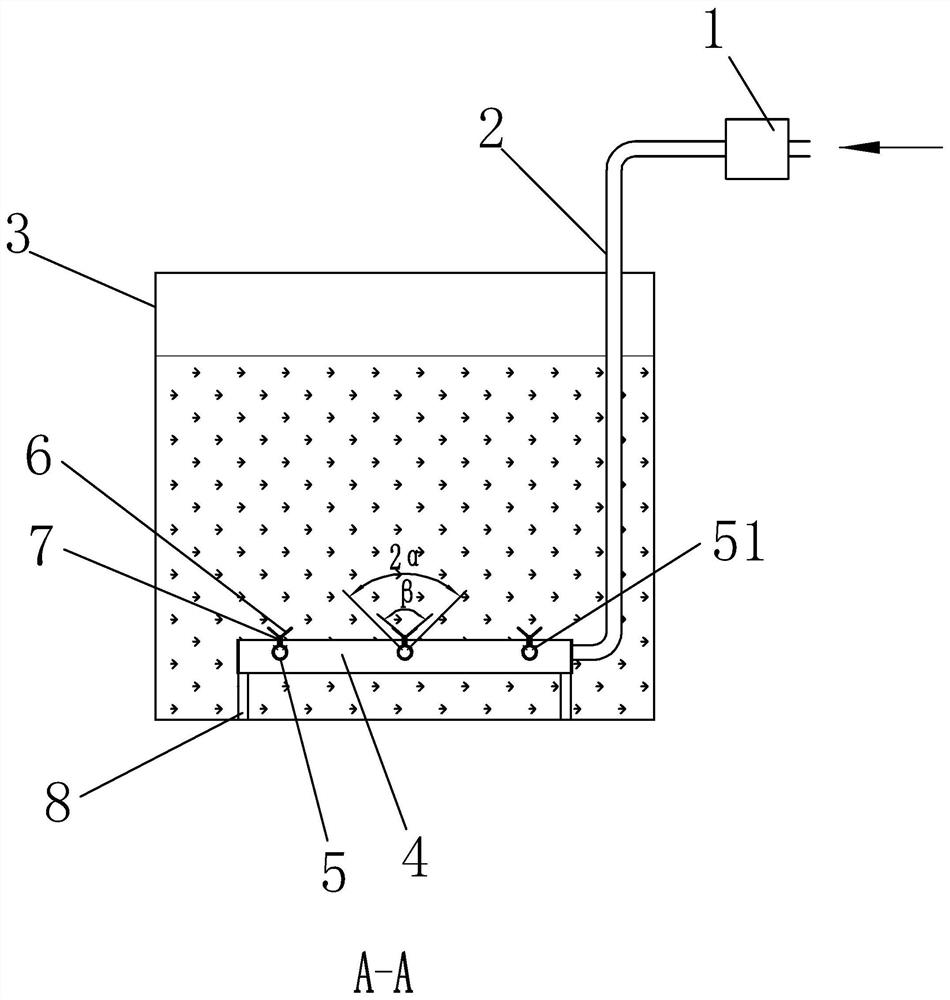

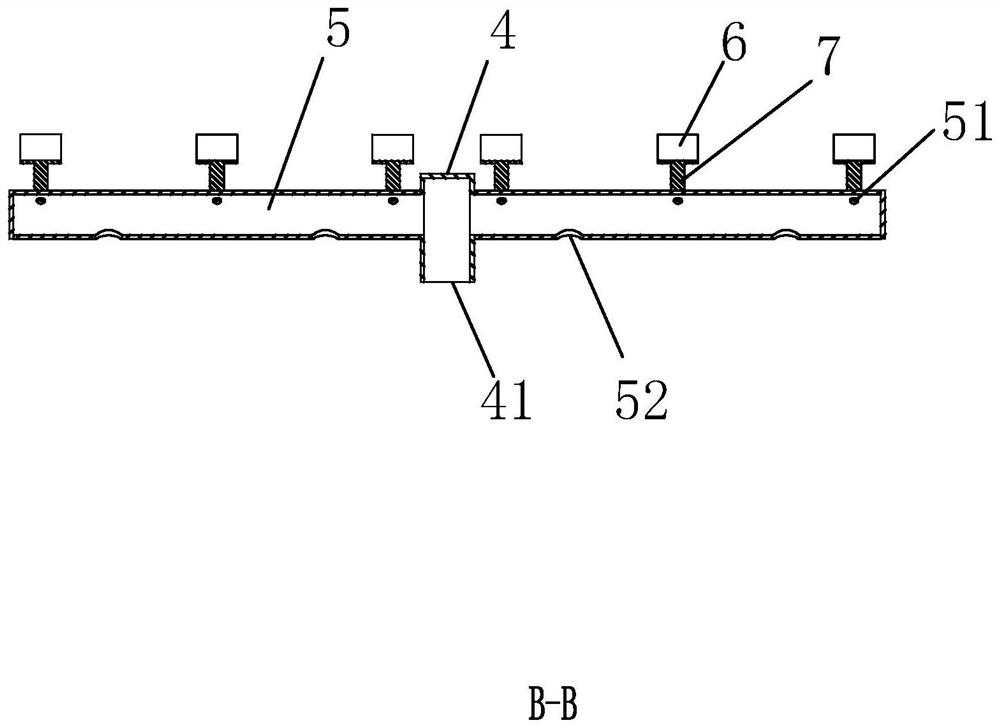

[0032]Embodiment 1: It includes a main pipe 4 and a branch pipe 5. The main pipe 4 is preferably a rectangular pipe. One end of the main pipe 4 communicates with the intake pipe 2 and the other end is closed. The branch pipes 5 are horizontally arranged on both sides of the main pipe 4. One end communicates with the main pipe 4 and the other end is closed. . A plurality of branch pipes 5 can be arranged on each side of the main pipe 4, and the branch pipes 5 on both sides can be staggered or arranged symmetrically. The axis of the branch pipes 5 and the main pipe 4 can be vertical or inclined at a certain angle. -500mm, the exhaust hole 51 can be arranged on the main pipe and the branch pipe, preferably only on the branch pipe 5. The main pipe and the branch pipe can be arranged in a straight line, a curve, a broken line, etc. respectively.

Embodiment 2

[0033] Embodiment two: if Figure 4 As shown, an annular pipe 9 is included, and the annular pipe 9 communicates with the intake pipe 2 . A connecting pipe piece 91 is arranged in the annular space of the annular pipe, and the two ends of the communicating pipe piece communicate with the annular pipe respectively. The annular pipe can be a rectangular ring, a circular ring or an elliptical ring, preferably the annular pipe 9 is a rectangle, and the annular space of the annular pipe is preferably evenly divided by the connecting pipe fitting 91, and the exhaust hole 51 is arranged on the annular pipe 9 and the connecting pipe fitting 91 . One or more connecting pipes 91 can be provided. When multiple connecting pipes are provided, the connecting pipes can be parallel to each other or intersect in a grid shape. The distance between the connecting pipes is preferably 300-1000mm.

[0034] Of course, when the annular pipe is included, multiple annular pipes can also be arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com