Impermeable wear-resistant concrete and preparation method thereof

A concrete and recycled concrete technology, which is applied in the field of building materials, can solve the problems of concrete impermeability and wear resistance that cannot meet the needs, and achieve the effect of improving impermeability, impermeability and wear resistance, and improving microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

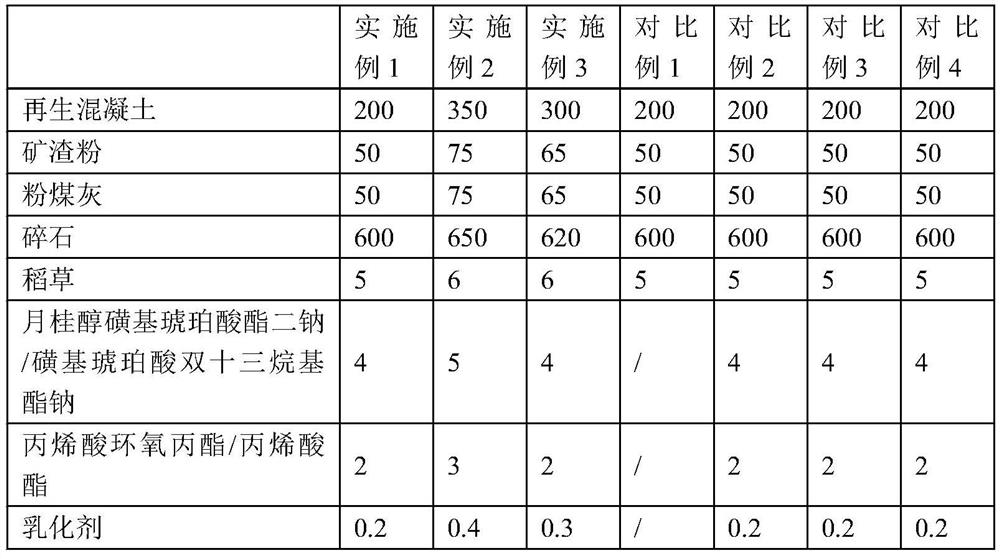

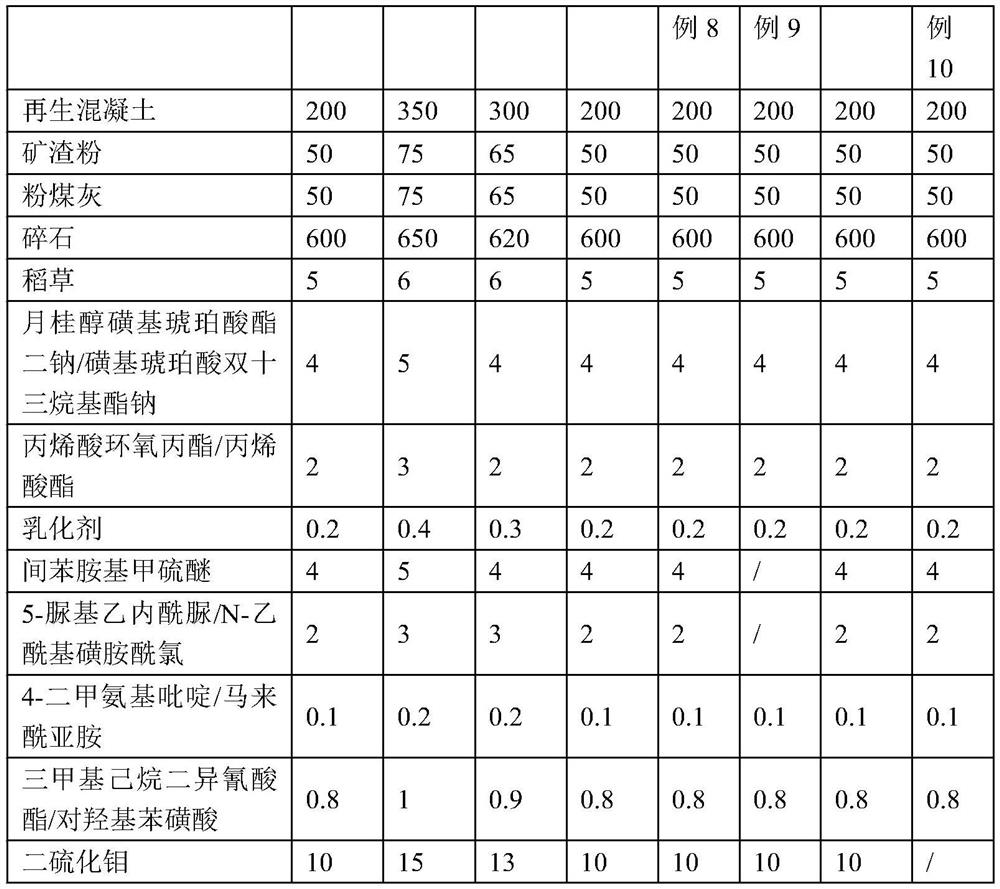

Embodiment 1

[0042] The application discloses an anti-seepage and wear-resistant concrete and a preparation method thereof. The preparation method comprises the following steps:

[0043] S1. Raw material mixing; mix recycled concrete, slag powder, fly ash and crushed stone, add straw cut into 20mm pieces while stirring, add 100 parts of water and stir for 5 minutes; then add lauryl alcohol which is well mixed Disodium sulfosuccinate, glycidyl acrylate and emulsifier were stirred for 30 minutes to obtain concrete raw materials;

[0044] S2. Compact molding; pour the concrete raw material of S1 into the mould, insert vertically with an inserting vibrator and insert it into the unprepared concrete of the lower layer and vibrate for 80s at 50 mm;

[0045] S3. Steam-cured concrete; pour the concrete raw materials of S1 into the mold for pre-curing, the pre-curing temperature is 30°C, and the time is 1h; cut the pre-cured products, and then steam-cure, the steam-curing temperature is 180°C, The...

Embodiment 2

[0048] The application discloses an anti-seepage and wear-resistant concrete and a preparation method thereof. The preparation method comprises the following steps:

[0049] S1. Raw material mixing; mix recycled concrete, slag powder, fly ash and crushed stone, add straw cut into 20mm pieces while stirring, add 220 parts of water and stir for 8 minutes; then add lauryl alcohol that is well mixed Disodium sulfosuccinate, glycidyl acrylate and emulsifier were stirred for 50 minutes to obtain concrete raw materials;

[0050] S2. Compact molding; pour the concrete raw material of S1 into the mould, insert vertically with an inserting vibrator and insert it into the unprepared concrete of the lower layer and vibrate for 100s at 100 mm;

[0051] S3. Steam-cured concrete; pour the concrete raw materials of S1 into the mold for pre-curing, the pre-curing temperature is 40°C, and the time is 1.5h; cut the pre-cured products, and then steam-cure, the steam-curing temperature is 200°C , p...

Embodiment 3

[0054] The application discloses an anti-seepage and wear-resistant concrete and a preparation method thereof. The preparation method comprises the following steps:

[0055] S1. Raw material mixing; mix recycled concrete, slag powder, fly ash and crushed stone, add straw cut into 20mm pieces while stirring, add 180 parts of water and stir for 7 minutes; then add lauryl alcohol which is well mixed Disodium sulfosuccinate, glycidyl acrylate and emulsifier were stirred for 40 minutes to obtain concrete raw materials;

[0056] S2. Compact molding; pour the concrete raw material of S1 into the mould, insert vertically with an inserting vibrator and insert it into the unprepared concrete of the lower layer and vibrate for 90s at 80 mm;

[0057] S3. Steam-cured concrete; pour the concrete raw materials of S1 into the mold for pre-curing, the pre-curing temperature is 35°C, and the time is 1.5h; cut the pre-cured products, and then steam-curing, the steam-curing temperature is 190°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com