Preparation method of recyclable cadmium adsorption ceramic powder foam concrete block

A foamed concrete and porcelain powder technology, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of inability to recycle, waste of adsorbent resources, and cost increase, so as to improve the efficiency of hydration reaction and the proportion of foam breaking, reduce Cadmium content, the effect of increasing pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

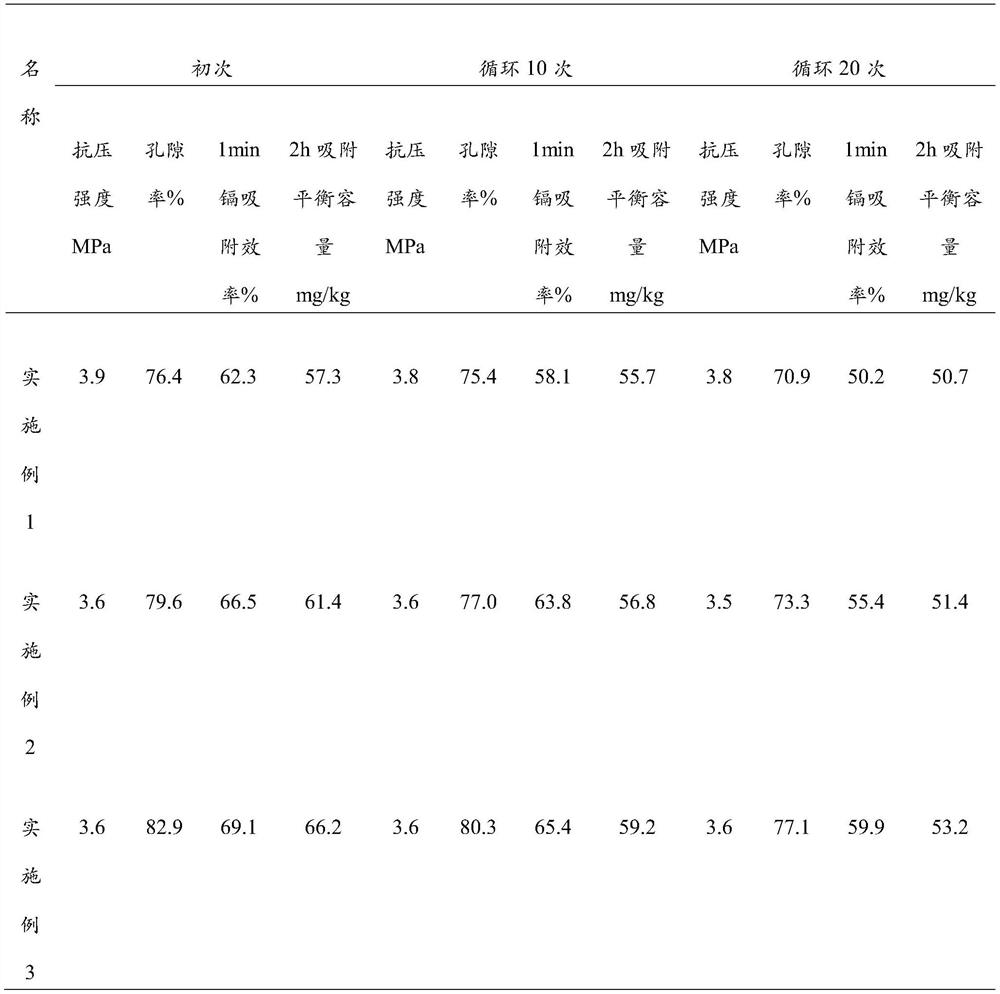

[0024] The porcelain powder is fired at 650°C for 0.5h, and the baked porcelain powder is mixed with gypsum, quartz sand, and lime in parts by mass of 70%, 10%, 10%, and 10%, and the water-solid ratio is 0.5. The amount of aluminum powder added in the foaming stage is 2‰ of the total mass of solid raw materials, and the added amount of diethylene glycol and syrup is 2‰ of the total mass of solid raw materials. The microwave heating oxidation temperature is 75°C and the time is 0.5h. Two samples were prepared, and the average compressive strength and cadmium adsorption efficiency of the blocks were tested for 28 days. After the adsorption experiment was completed, regeneration treatment was carried out at 40°C for 5 hours, and the compressive strength and cadmium adsorption experiments were continued. The experimental results are shown in Table 1.

Embodiment 2

[0026] According to the porcelain powder 700 roasting 0.75h, roasting porcelain powder, gypsum, quartz sand, lime 75%, 15%, 5%, 5% mixed, water-solid ratio 0.5. The amount of aluminum powder added in the foaming stage is 4‰ of the total mass of solid raw materials, and the added amount of diethylene glycol and syrup is 4‰ of the total mass of solid raw materials. The microwave heating oxidation temperature was 80°C and the time was 0.8h. Two samples were prepared for each implementation case, and the average compressive strength and cadmium adsorption efficiency of the blocks were tested for 28 days. After the adsorption experiment was completed, regeneration treatment was carried out at 40°C for 5 hours, and the compressive strength and cadmium adsorption experiments were continued. The experimental results are shown in Table 1.

Embodiment 3

[0028] According to the firing of porcelain powder at 750°C for 1 hour, the firing porcelain powder, gypsum, quartz sand, and lime are mixed at 80%, 10%, 0%, and 5%, and the water-solid ratio is 0.5. The amount of aluminum powder added in the foaming stage is 6‰ of the total amount of raw materials, and the amount of diethylene glycol and syrup added is 6‰ of the total amount of raw materials. The microwave heating oxidation temperature is 85°C and the time is 1.1h. Two samples were prepared for each implementation case, and the average compressive strength and cadmium adsorption efficiency of the blocks were tested for 28 days. After the adsorption experiment was completed, regeneration treatment was carried out at 40°C for 5 hours, and the compressive strength and cadmium adsorption experiments were continued. The experimental results are shown in Table 1.

[0029] Table 1

[0030]

[0031] As can be seen from the experimental results in Table 1, the ceramic powder foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com