Solvent-free low-temperature ball-milling preparation method of solid polycarboxylic slump retaining agent

A technology of polycarboxylic acid-based and slump-retaining agent is applied in the field of solvent-free low-temperature ball milling preparation of solid polycarboxylic acid-based slump-retaining agent and solid polycarboxylic acid-based slump-retaining agent, which can solve the problems of high temperature and complicated process, etc. Achieve the effect of unaffected performance, no solvent poisoning, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

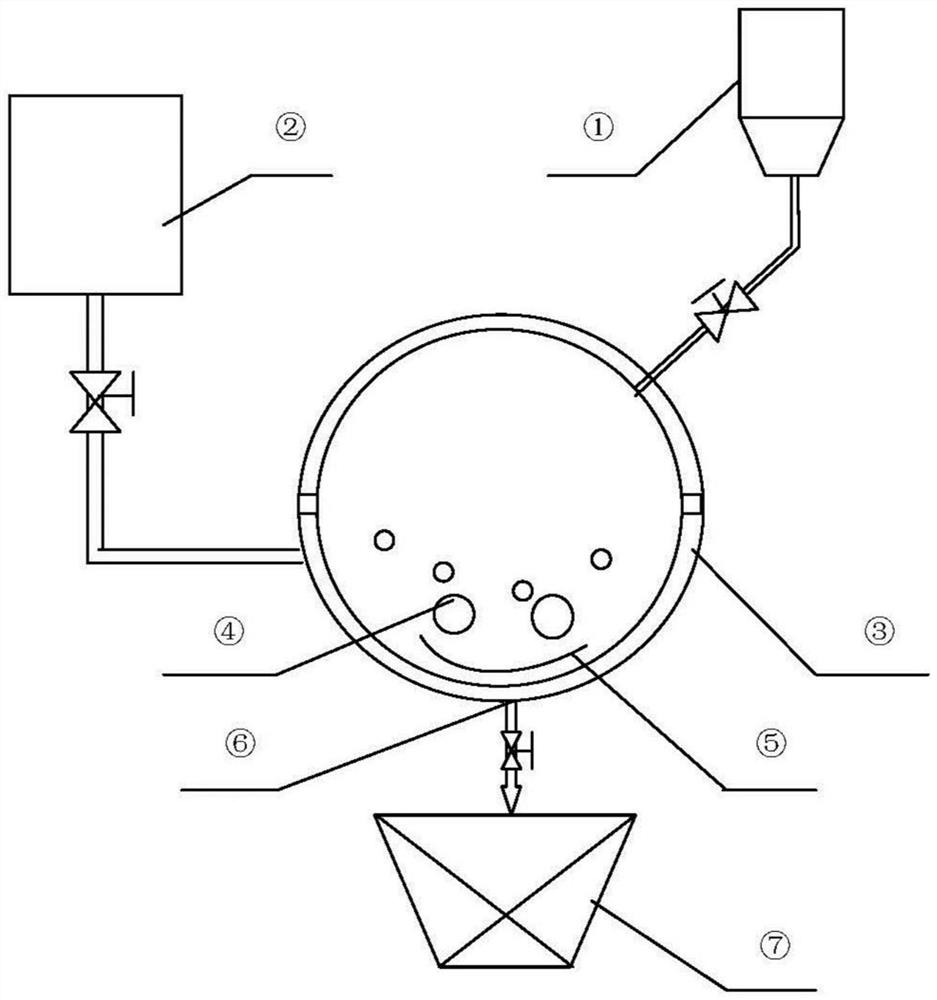

Method used

Image

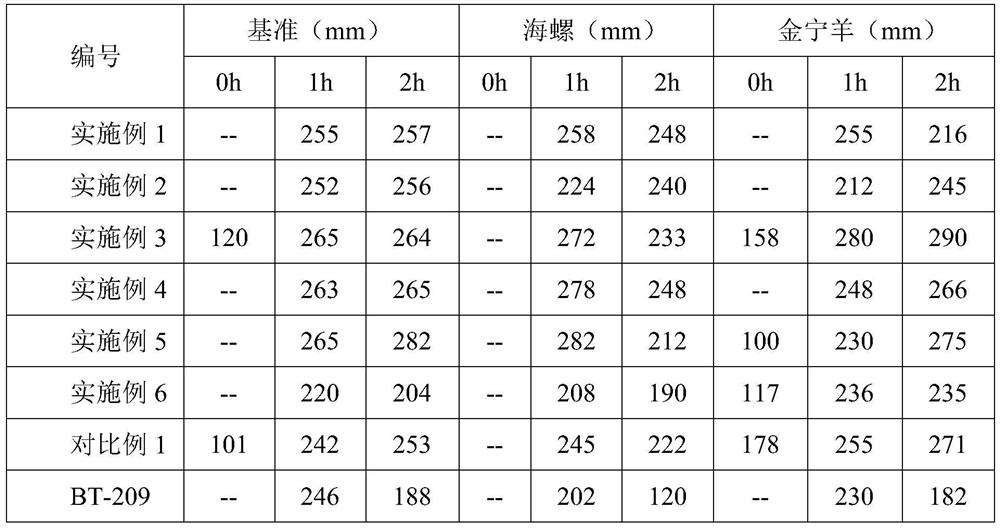

Examples

Embodiment 1

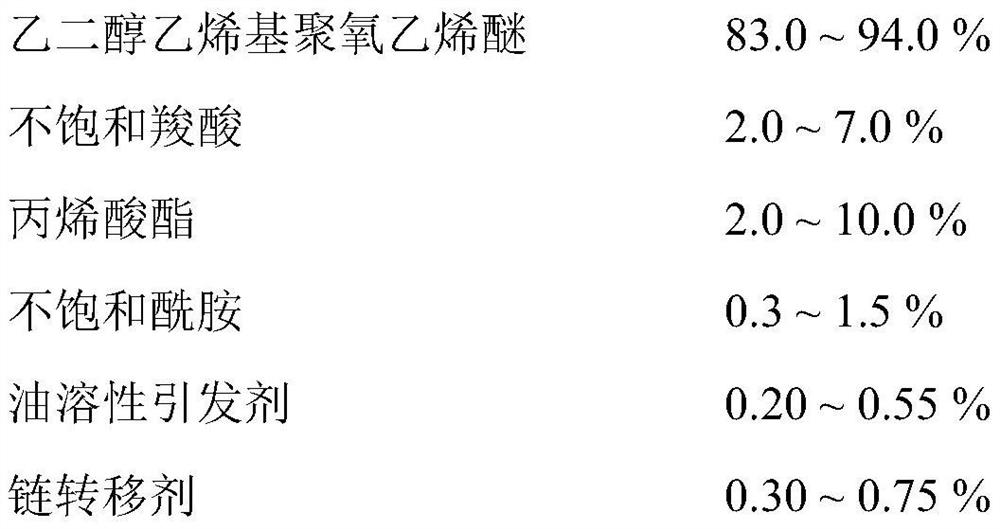

[0030] Put 17.0kg of molten ethylene glycol vinyl polyoxyethylene ether (molecular weight 3000), 0.2kg of acrylamide, 0.6 kg of acrylic acid, 1.9kg of hydroxyethyl acrylate and 0.14kg of octyl 3-mercaptopropionate into the ball mill and close the lid, open Add 0.045kg of benzoyl peroxide to the initiator feed valve; then, while turning on the ball mill for ball milling, open the chilled water valve of the jacket of the ball mill, and control the temperature at 60±2°C; add the remaining 0.045kg of benzoyl peroxide after 5 minutes of ball milling Formyl, continue ball milling for 5 minutes, stop the machine and open the discharge valve, and the finished product is sent to the cryogenic pulverizer for pulverization and discharge.

Embodiment 2

[0032] Add 18.4kg molten ethylene glycol vinyl polyoxyethylene ether (molecular weight 6000), 0.1kg N-methylolacrylamide, 0.4kg methacrylic acid, 0.9kg hydroxyethyl acrylate and 0.10kg octyl mercaptan to the ball mill and Close the lid, open the feed valve of the initiator, and add 0.05kg of azobisisobutyronitrile; then, while turning on the ball mill for ball milling, open the chilled water valve of the jacket of the ball mill, and control the temperature at 60±2°C; add the remaining 0.05kg azobisisobutyronitrile, continue ball milling for 5 minutes, stop the machine and open the discharge valve, and the finished product is sent to the cryogenic pulverizer for pulverization and discharge.

Embodiment 3

[0034] Put 17.1kg of molten ethylene glycol vinyl polyoxyethylene ether (molecular weight 3000), 0.1kg of methacrylamide, 0.6kg of acrylic acid, 2.0kg of hydroxypropyl acrylate and 0.10kg of decyl mercaptan into the ball mill and close the lid, open and trigger Add 0.05kg of dimethyl azobisisobutyrate to the feeding valve of the agent; then, while turning on the ball mill for ball milling, open the chilled water valve of the jacket of the ball mill, and control the temperature at 60±2°C; add the remaining 0.05kg after 7 minutes of ball milling Dimethyl azobisisobutyrate, continue ball milling for 7 minutes, stop the machine and open the discharge valve, and the finished product is sent to the cryogenic pulverizer for pulverization and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com