Conductive nylon masterbatch with graphene-carbon nanotube composite structure and preparation method thereof

A technology of graphene composite and carbon nanotubes, applied in the field of conductive nylon conductive masterbatch and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

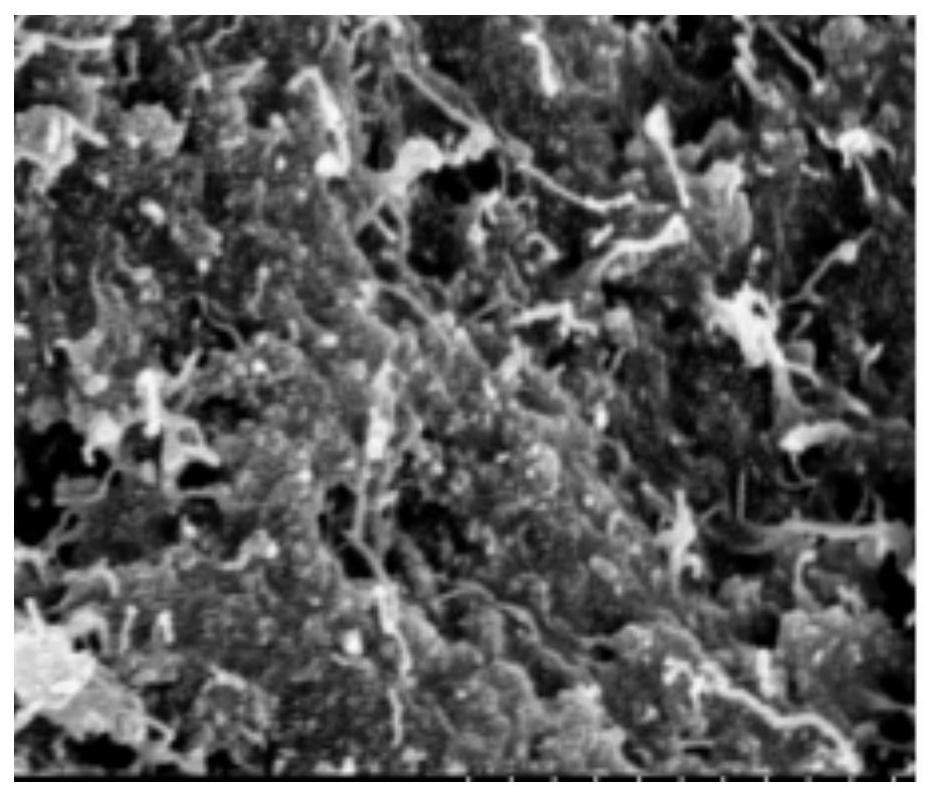

Image

Examples

Embodiment 1

[0061] Take two 1000ml beakers, respectively configure 400g of mixed concentrated acid of nitric acid and sulfuric acid at a ratio of 1:3, add 5 grams of commercially available graphite and 5 grams of carbon nanotubes to them respectively, place the two beakers in an ultrasonic water tank, adjust The temperature of the water tank is 65°C, and after ultrasonic oscillation at a frequency of 25KHz for 4 hours, the two mixed slurries obtained are centrifuged at 4000r / min for 10 minutes to separate the two mixed slurries into separate layers. In this way, the bottom black graphene suspension and carbon nanotube suspension are separated. After repeatedly washing the two suspensions with water to make the pH value reach 6, the two suspensions were dried in a vacuum oven at 70° C. to constant weight to obtain 4.8 grams of acidified graphene and 4.8 grams of acidified carbon nanotubes.

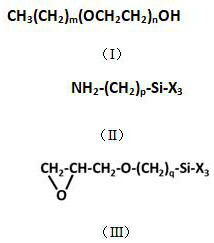

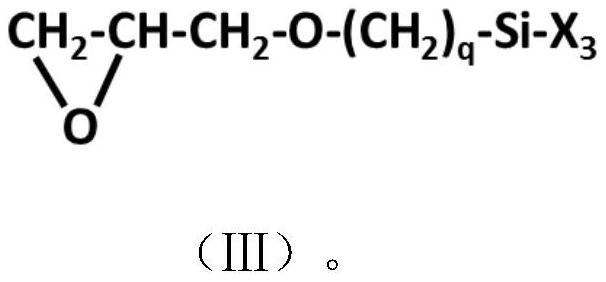

[0062] Take another two 500ml beakers, add 24 grams of aliphatic vinyl ether (A) respectively, then a...

Embodiment 2

[0071] Take two 3000ml beakers, respectively configure 1000g of mixed concentrated acid of nitric acid and sulfuric acid at a ratio of 1:3, add 50 grams of graphene to one of the beakers, add 50 grams of carbon nanotubes to the other beaker, and place the beaker in an ultrasonic water tank In the process, adjust the temperature of the water tank to 70°C and ultrasonically oscillate at a frequency of 40KHz for 8 hours, then use a centrifuge to separate the two mixed slurries at 4000r / min for 10 minutes to separate the mixed slurries , so as to separate the bottom black graphene suspension and carbon nanotube suspension. The suspension was repeatedly washed with water to make the pH value reach 6, and the two suspensions were dried in a vacuum oven at 80° C. to constant weight to obtain 48.5 grams of acidified graphene and 48.3 grams of acidified carbon nanotubes.

[0072] Take another two 1000ml beakers, add 100 grams of aliphatic vinyl ether (D) respectively, then add 300 gram...

Embodiment 3

[0082] Take two 3000ml beakers, respectively configure 2000g of mixed concentrated acid of nitric acid and sulfuric acid at a ratio of 1:3, add 20 grams of commercially available graphene and 10 grams of carbon nanotubes therein, and place the two beakers in an ultrasonic water tank. Adjust the temperature of the water tank to 60°C, and ultrasonically oscillate at a frequency of 25KHz for 4 hours, then use a centrifuge to separate the two mixed slurries at 4000r / min for 10 minutes, so that the two mixed slurries are separated into layers , to separate the bottom black graphene suspension and carbon nanotube suspension. Wash the two suspensions repeatedly with clean water to make the pH value above 6, then dry the two suspensions in a vacuum oven at 75°C to constant weight to obtain 19.6 grams of acidified graphene and 9.8 grams of acidified carbon nanotubes .

[0083]Take another two 1000ml beakers, add 200 grams of aliphatic vinyl ether (A) respectively, then add 300 grams o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com