Patents

Literature

30 results about "Carbon nanotube chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanotube chemistry involves chemical reactions, which are used to modify the properties of carbon nanotubes (CNTs). CNTs can be functionalized to attain desired properties that can be used in a wide variety of applications. The two main methods of CNT functionalization are covalent and non-covalent modifications.

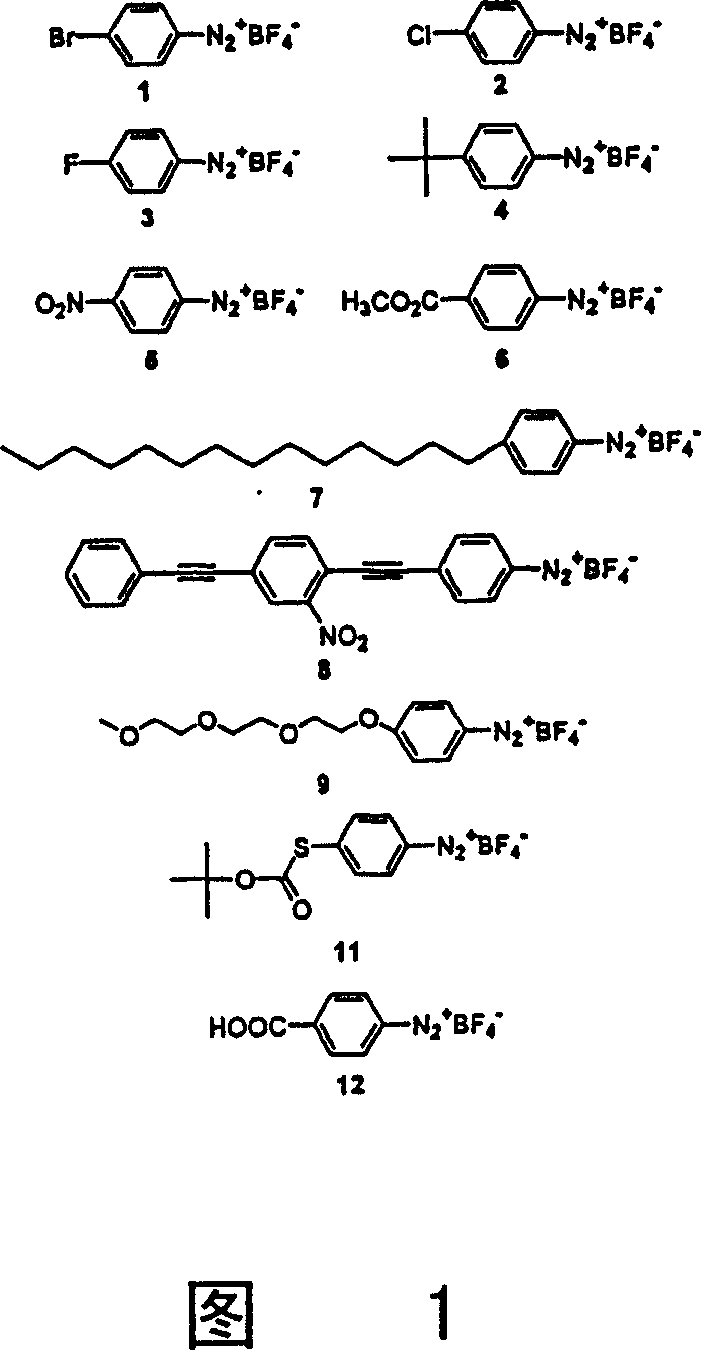

Carbon nanotubes derivatized with diazonium species

InactiveUS20050207963A1Advantage of scalabilityMaterial nanotechnologyPigmenting treatmentElectrochemistryOrganic compound

Owner:RICE UNIV

Process for attaching molecular wires and devices to carbon nanotubes and compositions thereof

InactiveUS20050074613A1Advantage of scalabilityPigmenting treatmentMaterial nanotechnologyElectrochemistryOrganic compound

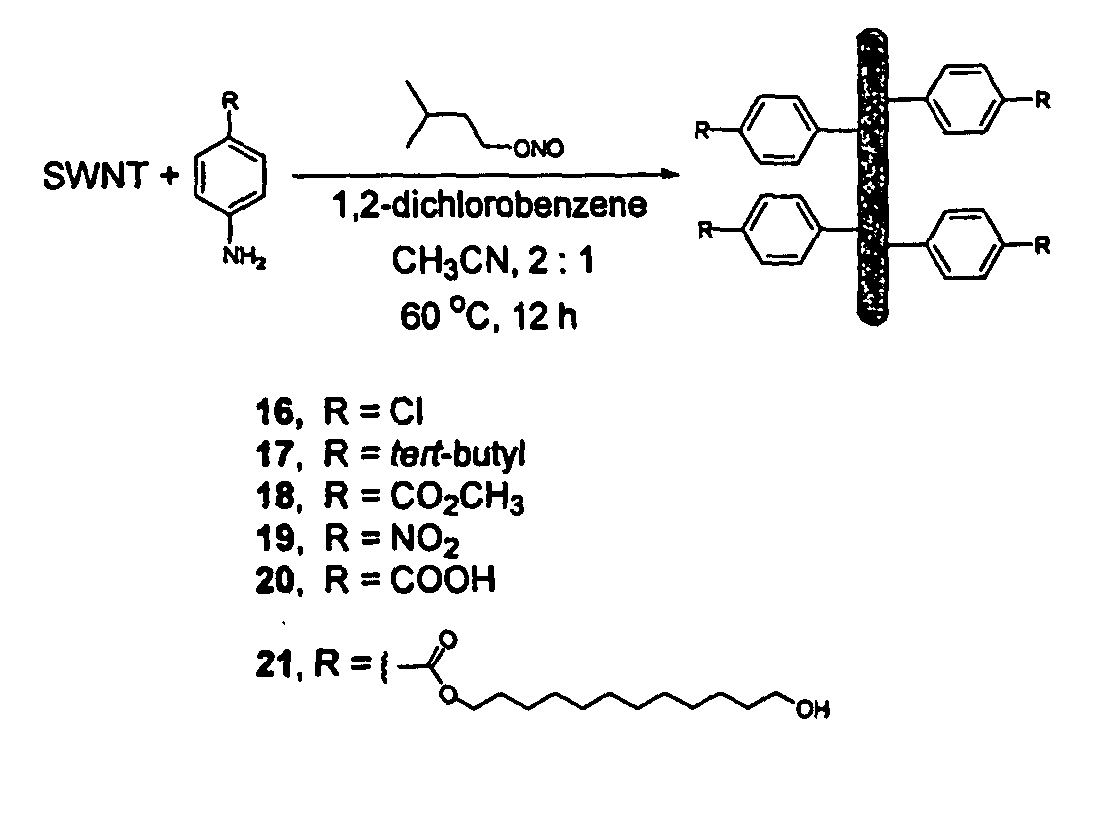

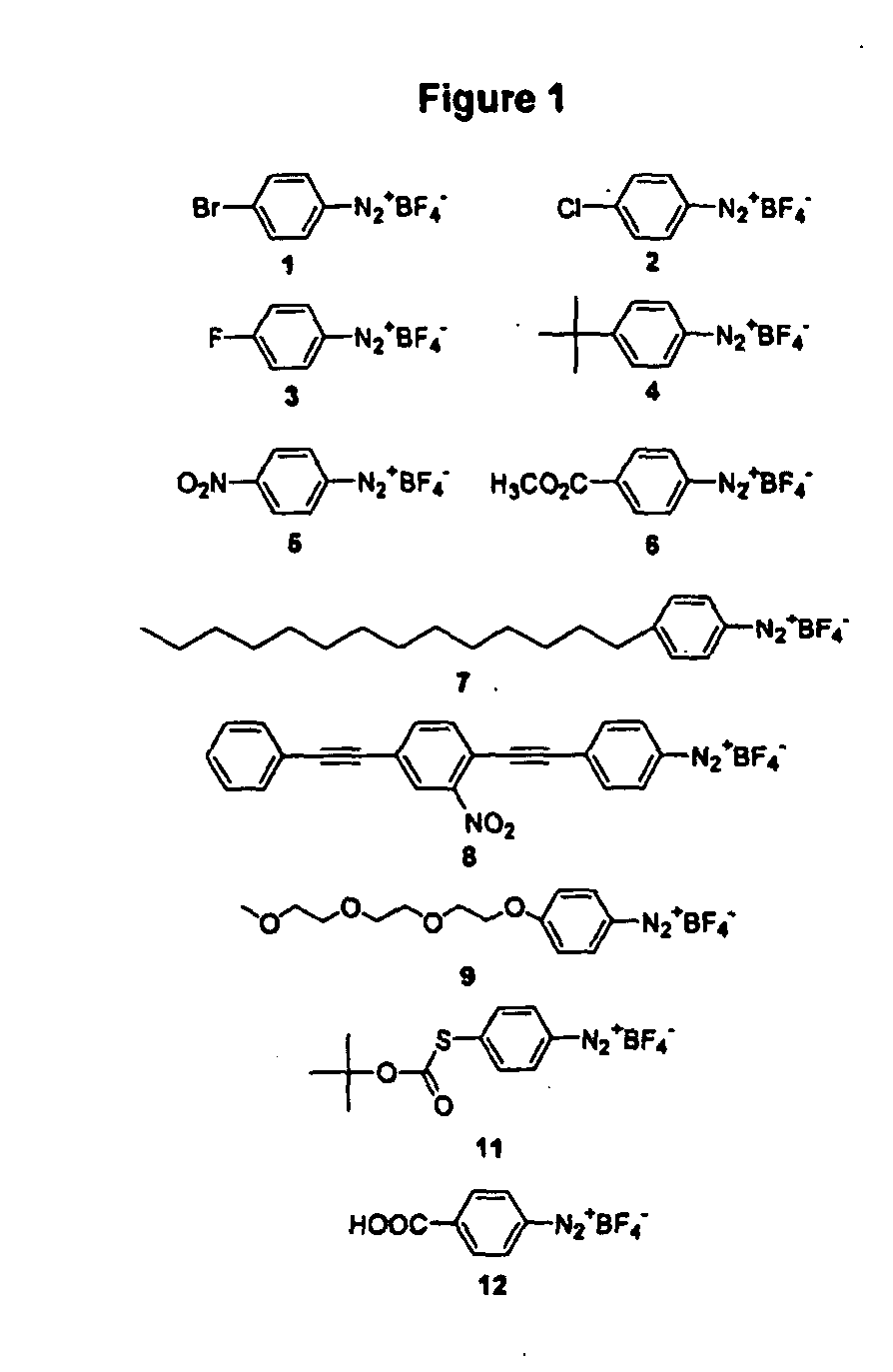

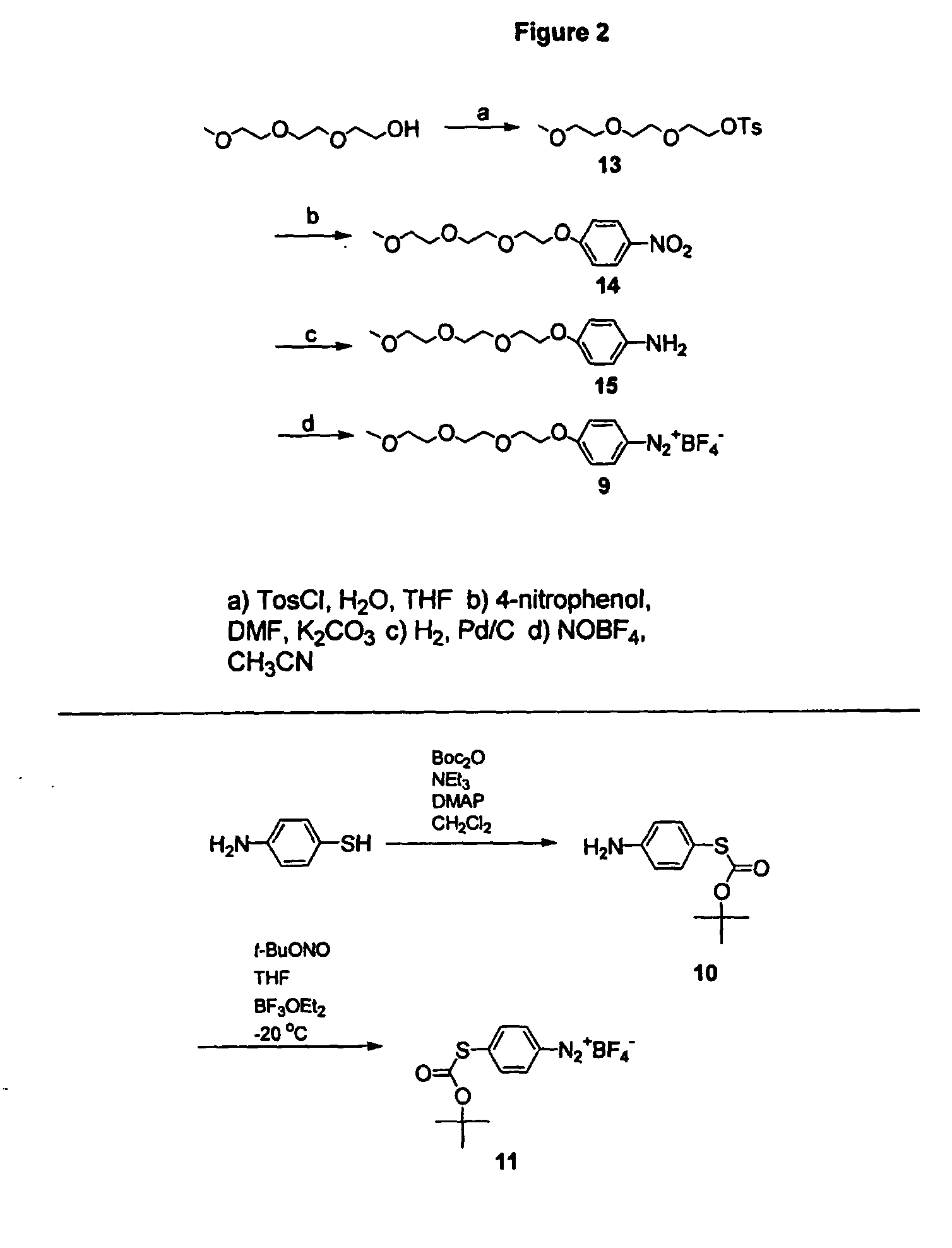

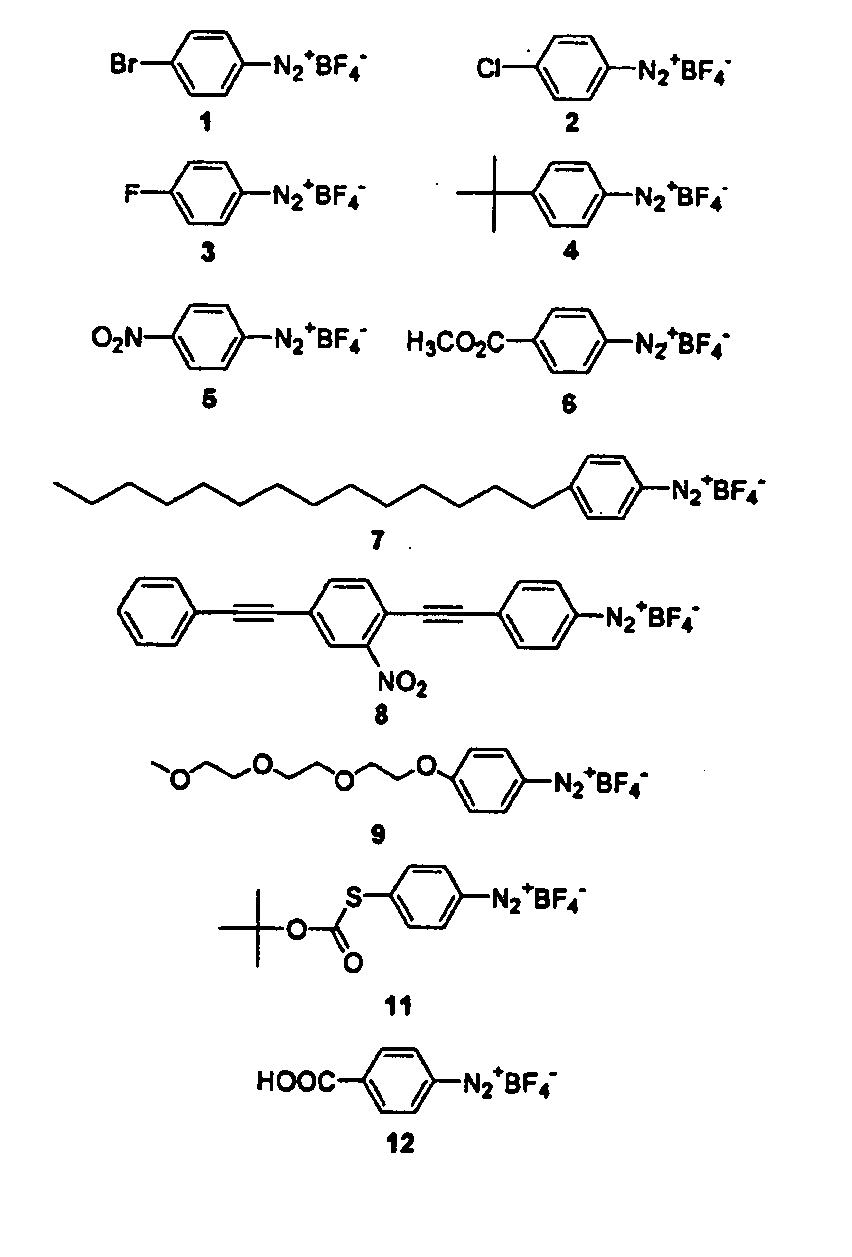

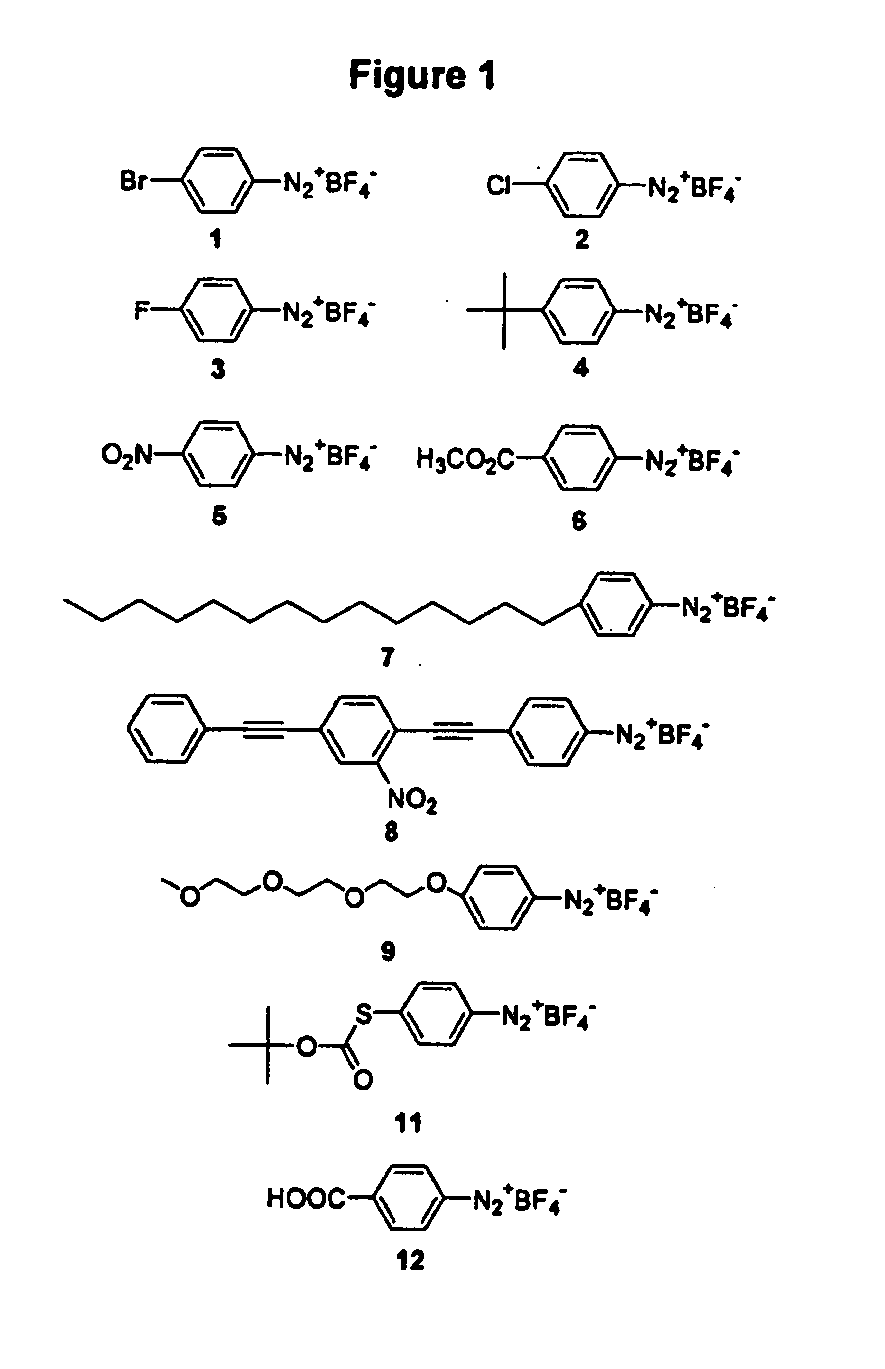

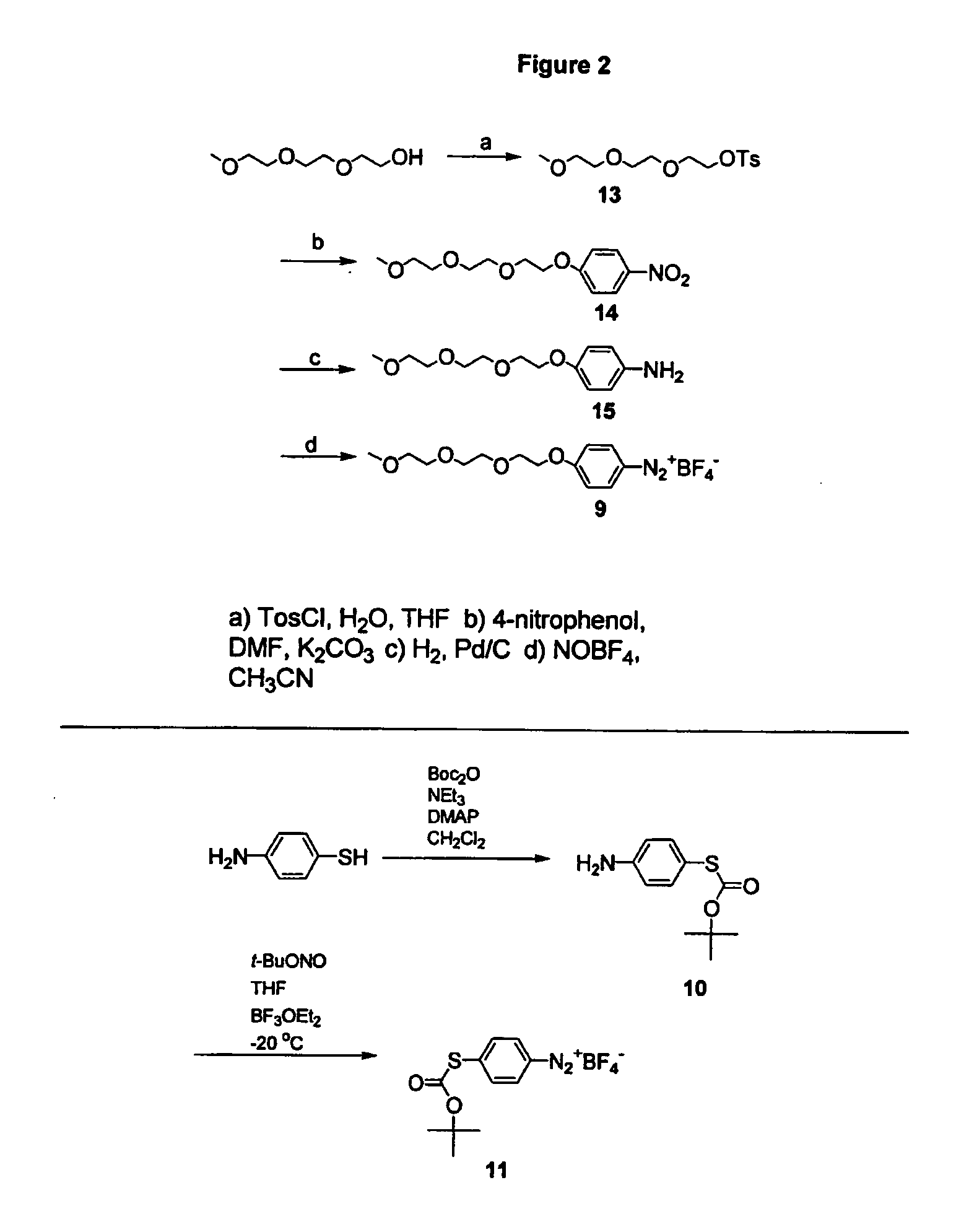

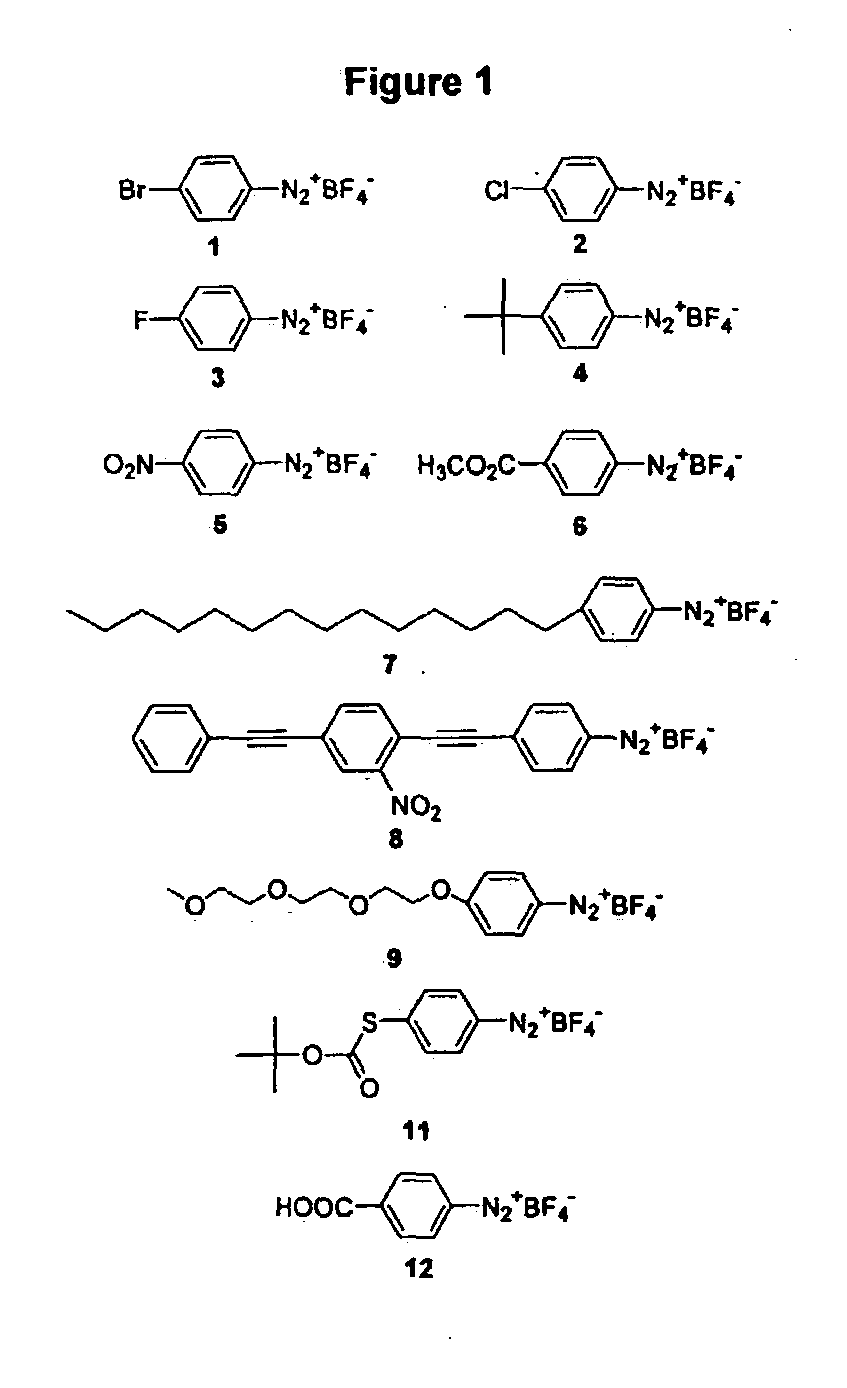

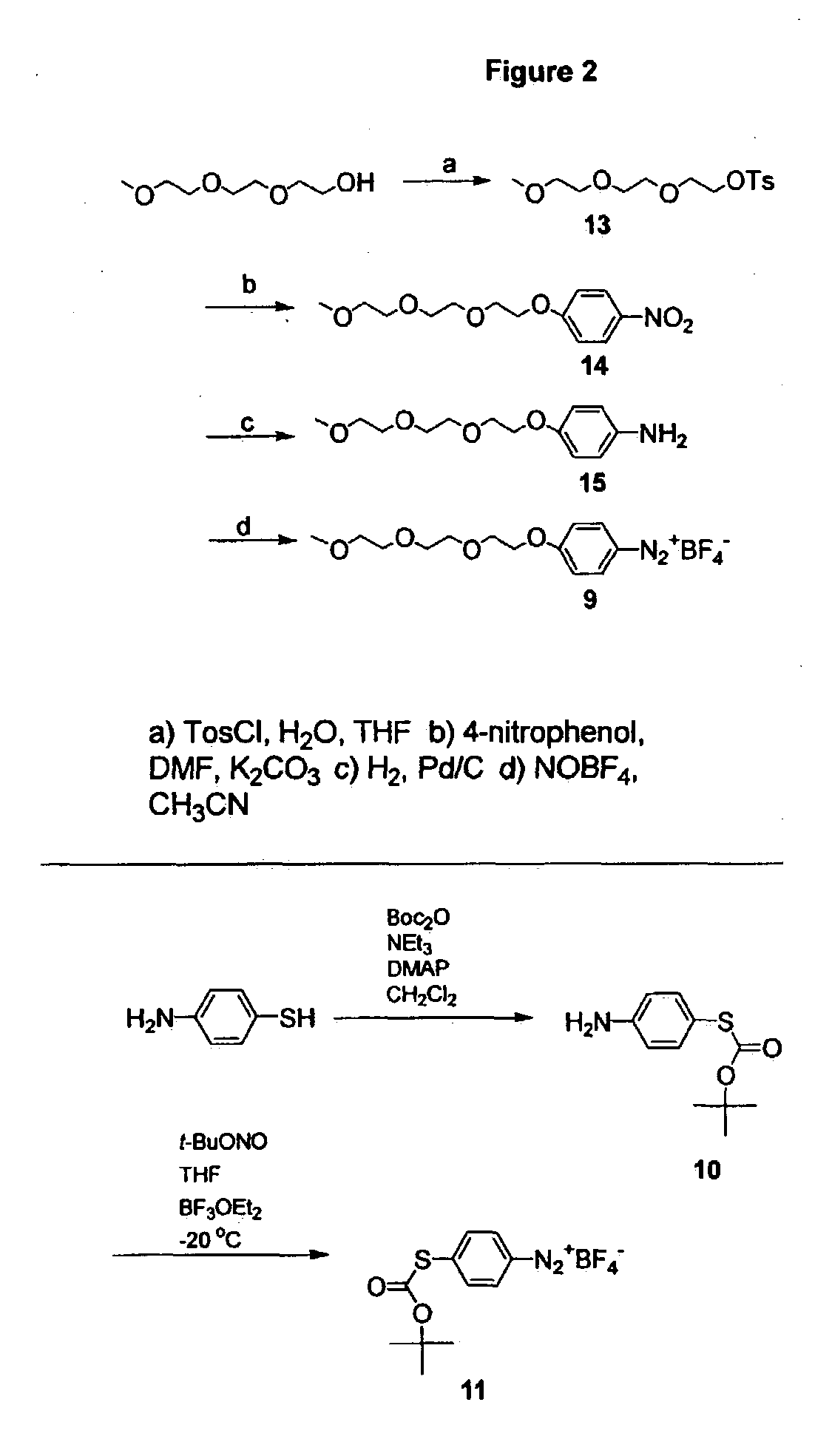

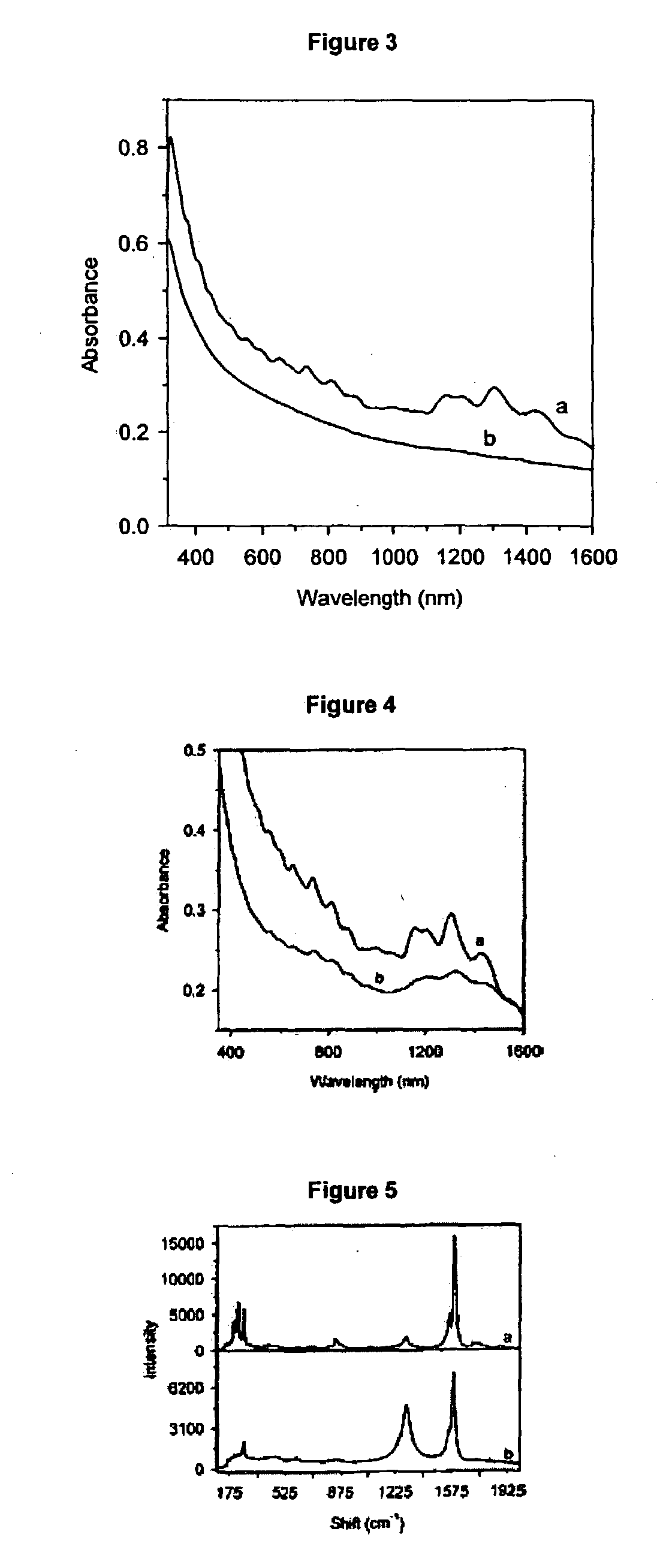

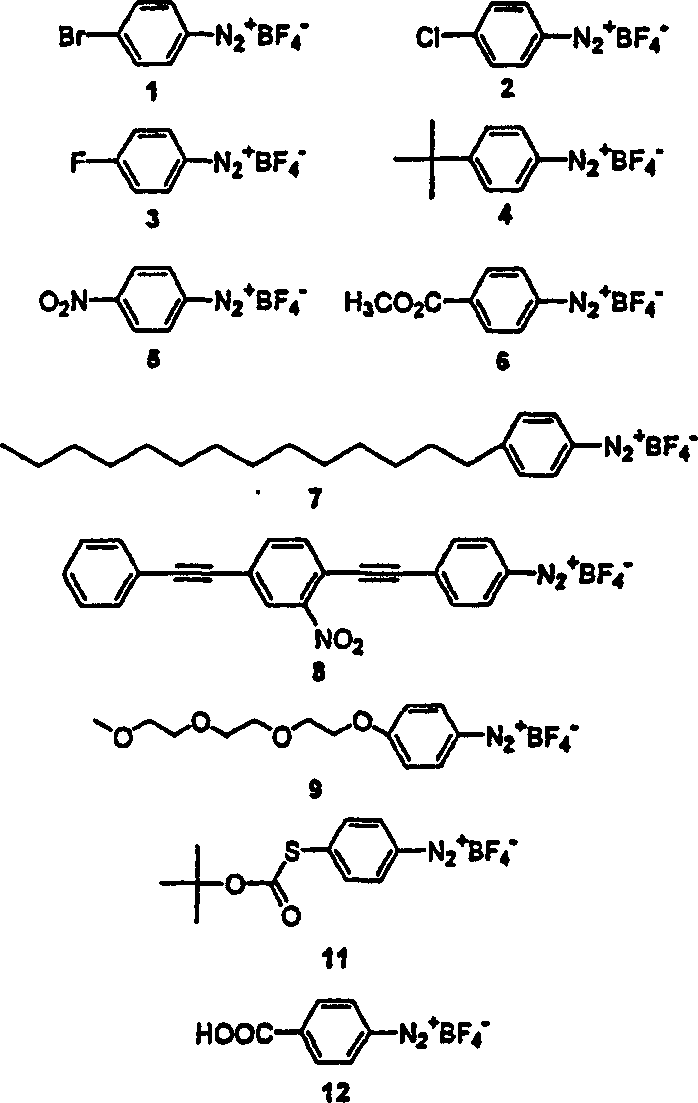

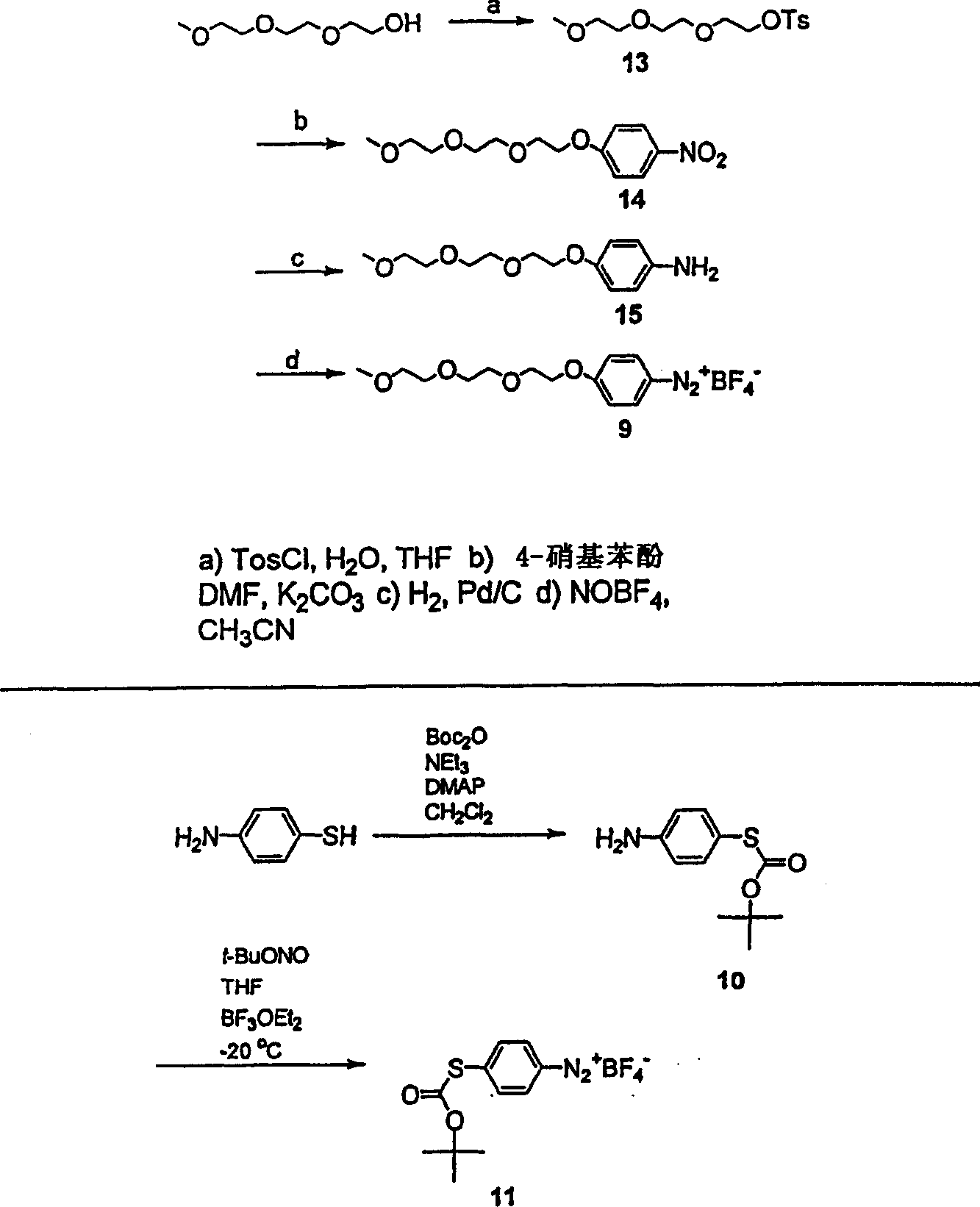

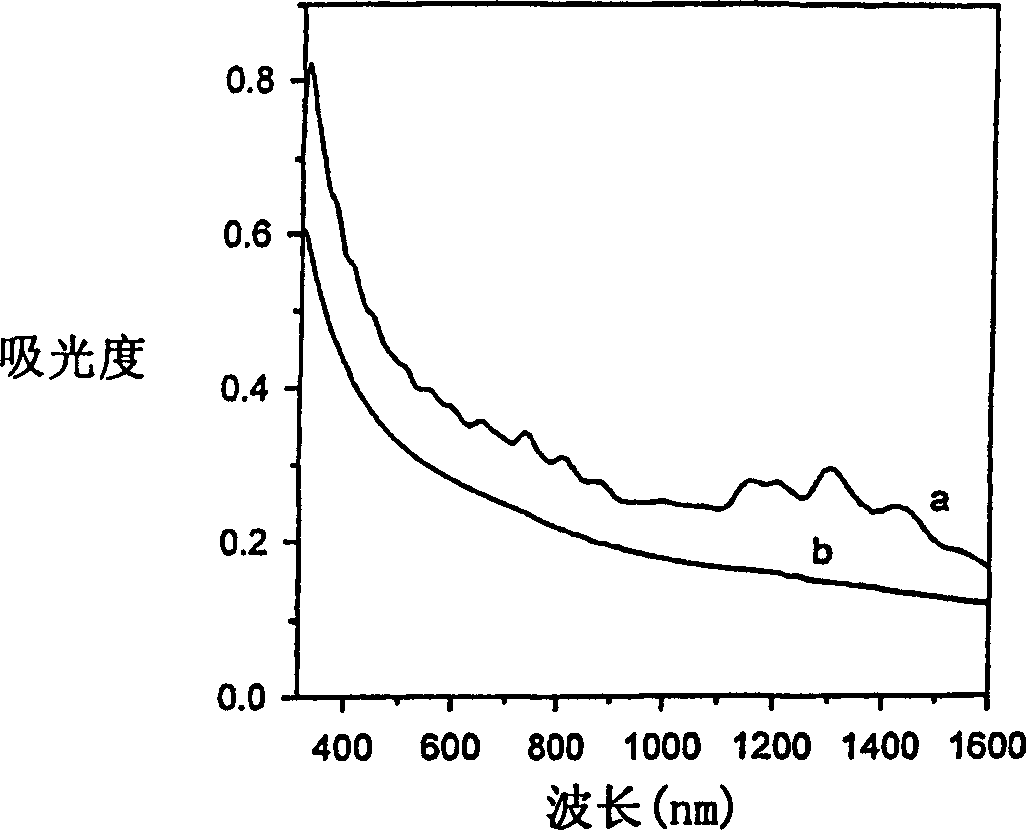

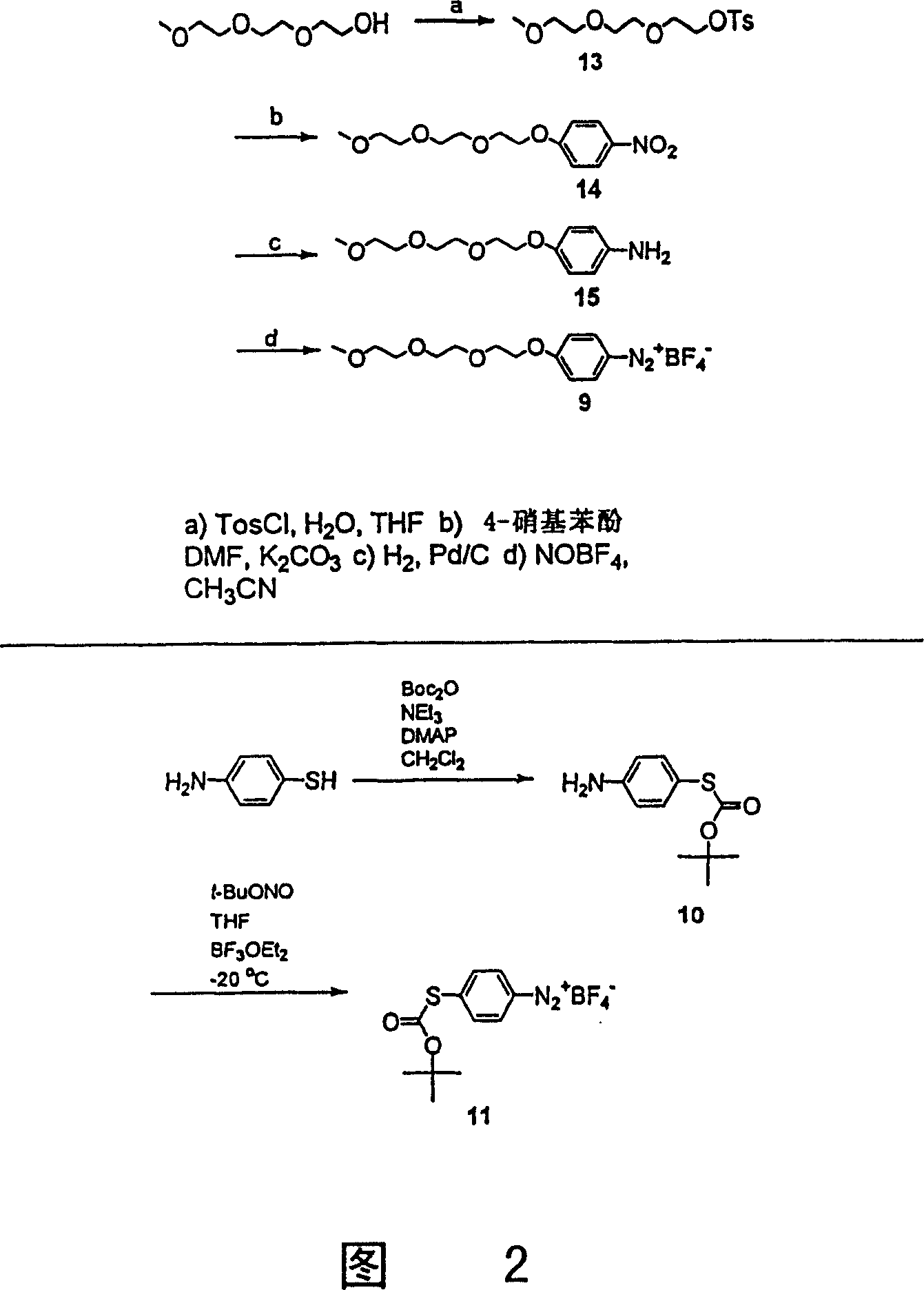

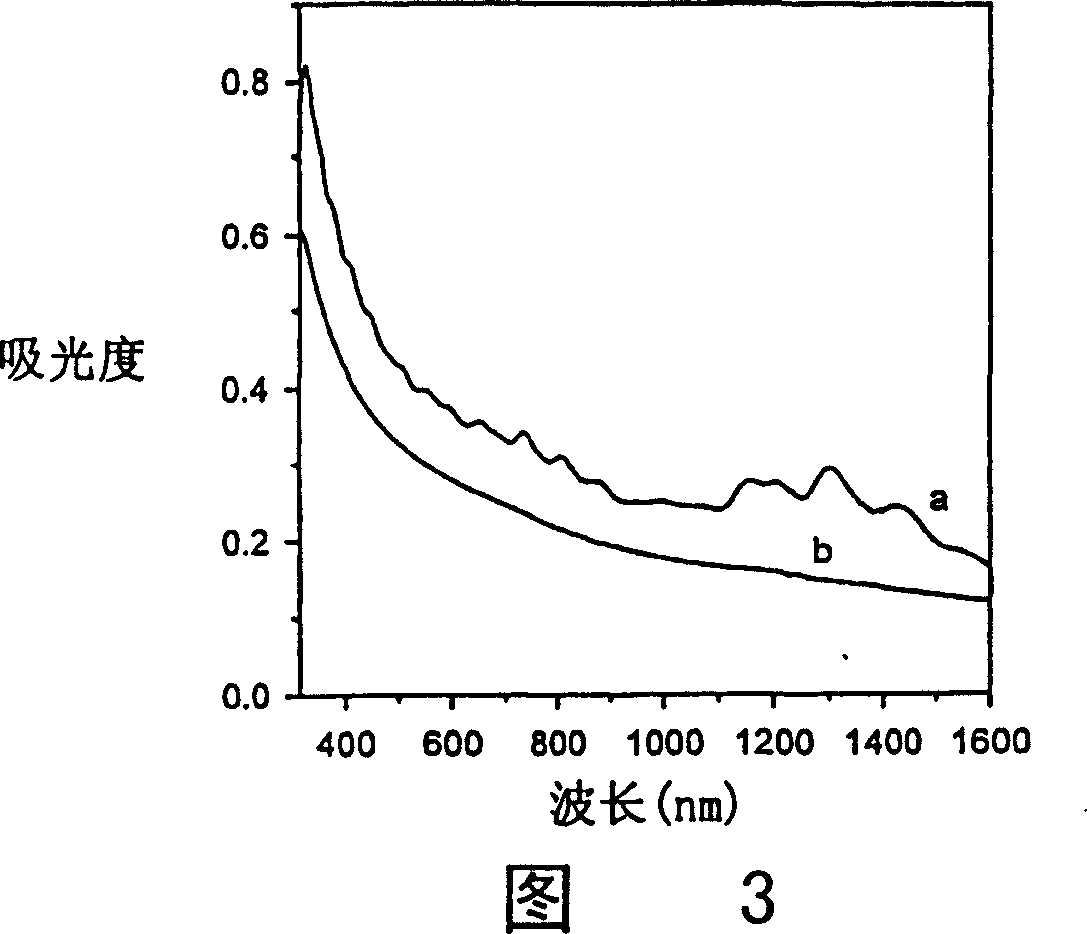

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and-sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or pre-formed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

Process for making polymers comprising derivatized carbon nanotubes and compositions thereof

InactiveUS20050074390A1Advantage of scalabilityMaterial nanotechnologyPigmenting treatmentElectrochemistryOrganic compound

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or pre-formed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

Preparation method of carbon nano tube-copper oxide composite powder

InactiveCN101716677AGood dispersionHigh activityLiquid/solution decomposition chemical coatingCopper platingCarbon nanotube

The invention discloses a preparation method of carbon nano tube-copper oxide composite powder, which relates to a preparation method of carbon nano tube copper-base composite powder. The invention solves the problems that complete and continuous plating is difficult to form on the carbon nano tube surface and the plating thickness is not easy to control in the tradition technique. The method of the invention is realized in a way as follows: the carbon nano tubes are pretreated orderly by oxidization, sensitization and activation, and copper oxides are chemically plated on the carbon nano tubes, thereby obtaining the carbon nano tube-copper oxide composite powder. The invention improves the dispersibility and the activation capacity of the carbon nano tubes through the pretreatment before plating, and avoids the subsidiary reaction in the process of chemical plating, thereby finally obtaining the continuous copper oxide plating on the carbon nano tube surface, and the coverage rate of the plating reaches 85-95%; and the invention has the advantages of uniform plating and controllable plating thickness. The wetting property of the carbon nano tube and the metal base after the carbon nanometer tube is chemically plated with copper oxides is enhanced, thereby laying foundation for applications of carbon nano tubes in the field of composite materials.

Owner:HARBIN INST OF TECH

Preparation for polymer and method for chemically modifying carbon nano-tube

InactiveCN101104658AAvoid destructionAvoid cutsPigment treatment with macromolecular organic compoundsEnd-groupAtom-transfer radical-polymerization

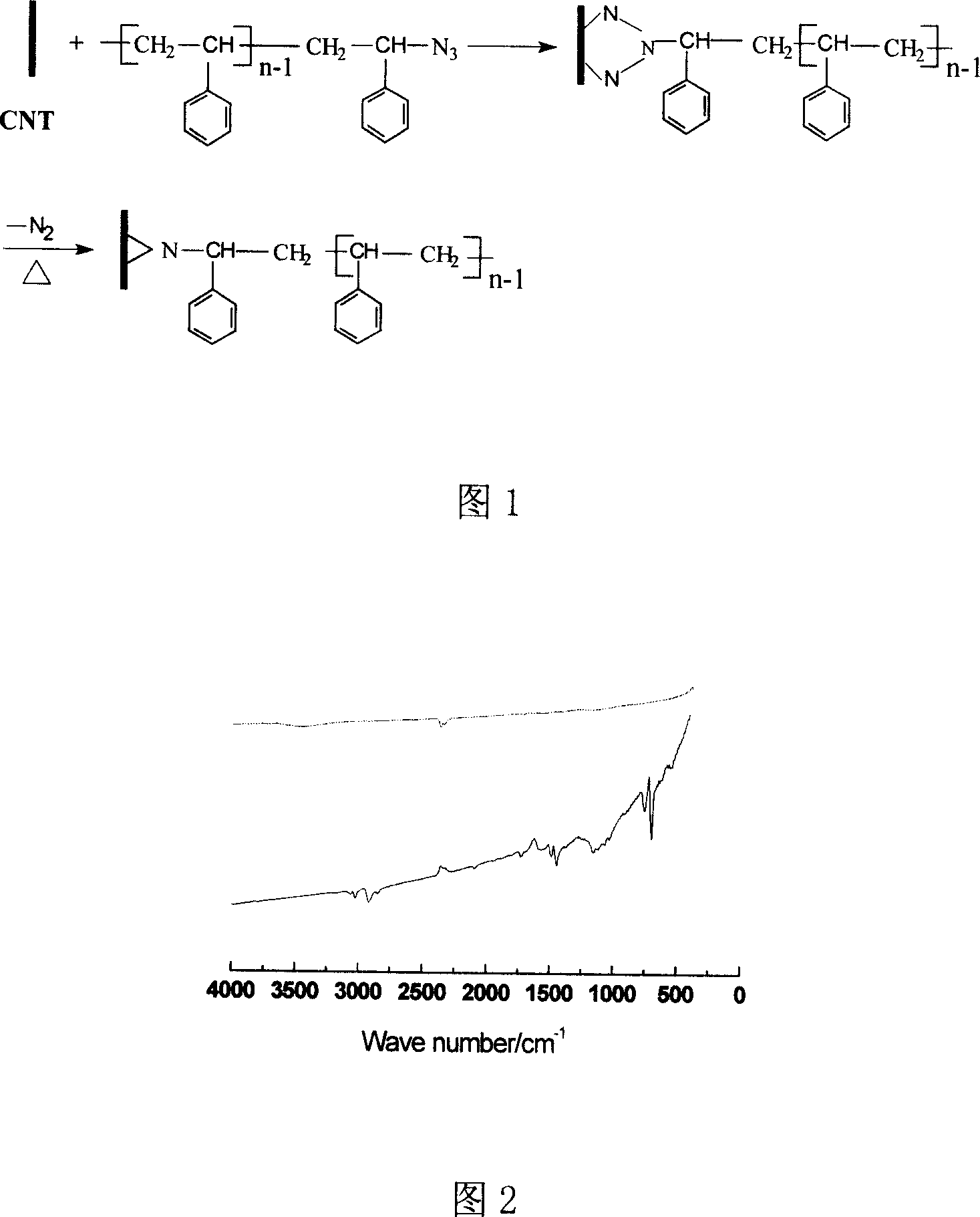

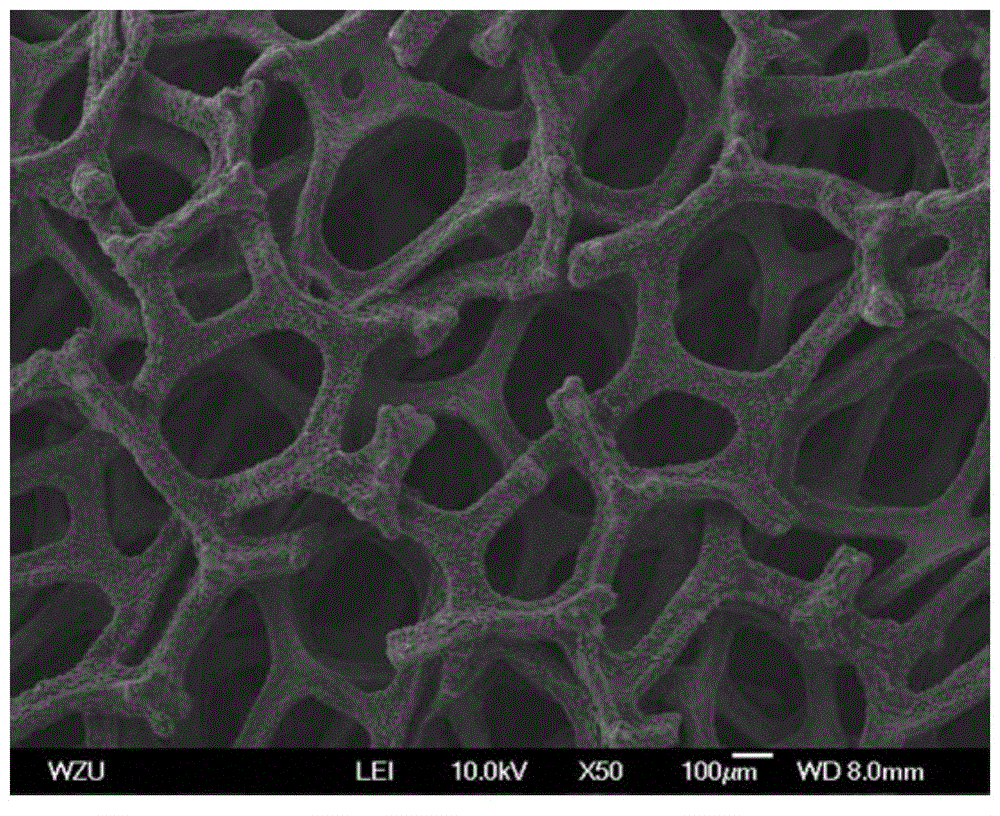

The invention discloses a preparation method of an azido blocking polymer and a method of the chemical modification of the azido blocking polymer for the surface of carbon nano tubes. Polymer whose end group is provide with a halogen is synthesized by the means of atom transfer free radical polymerization, and the halogens are transferred into azide groups through azido reaction, then the polymer whose end groups are the azide groups is obtained. The polymer is connected to the surface of the carbon nano tubes by means of a cycloaddition reaction between azido and single-walled or multi-walled carbon nano tubes, the chemical modification to the carbon nano tube is realized. The azide groups are used as a medium to make polymer graft, so as to avoid the damage to the tube walls of the carbon nano tubes and the cutting to the carbon nano tubes caused by the acid treatment, therefore, the soluble all carbon nano tubes can be obtained. The invention is of important significance in the studies and applications of the chemical and physical properties of the soluble carbon nano tubes.

Owner:TONGJI UNIV

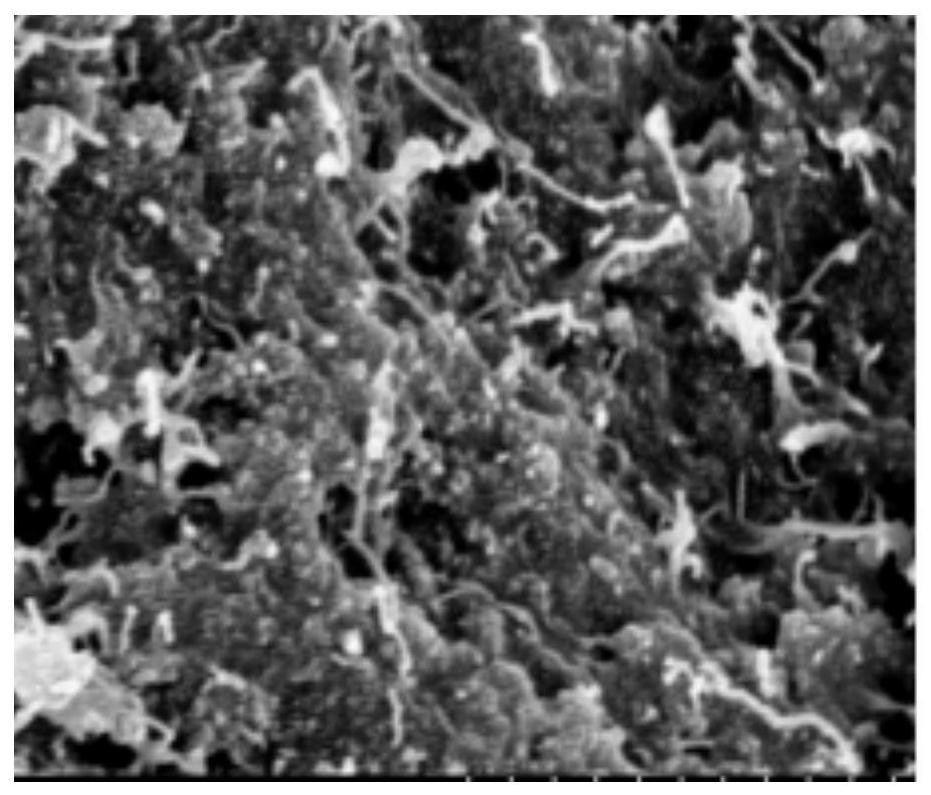

Method for directly growing carbon nanotube on foamed nickel substrate so as to prepare battery electrodes

ActiveCN104577059AImprove bindingImprove performanceAlkaline accumulator electrodesNickel substrateCarbon nanotube

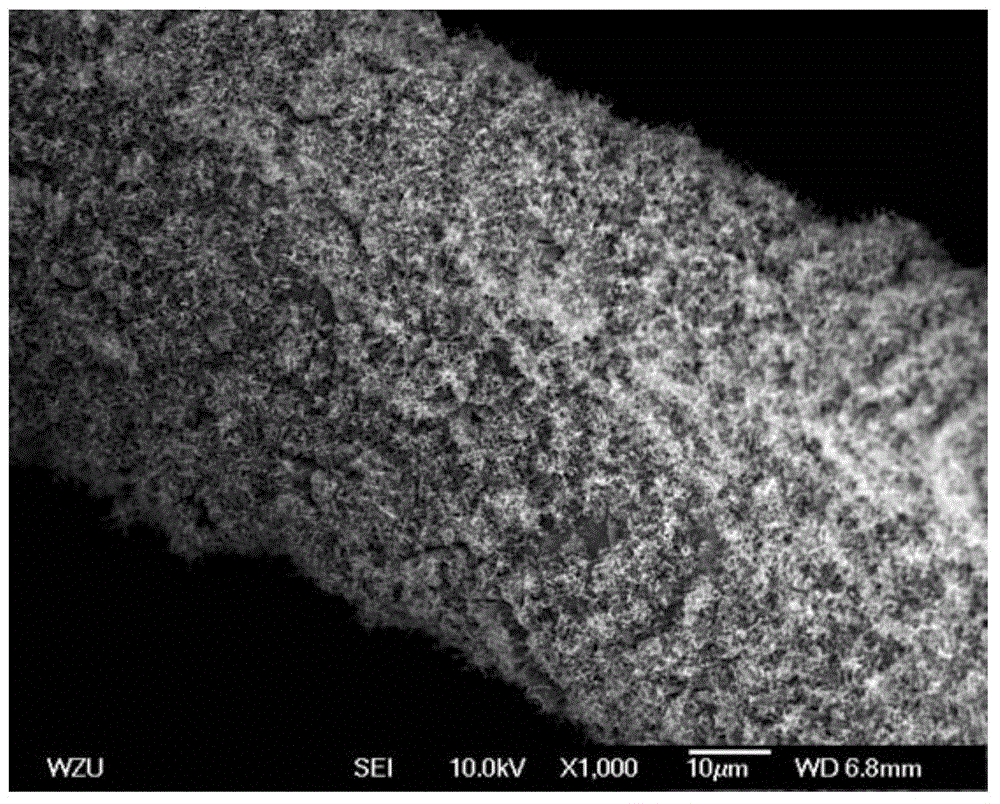

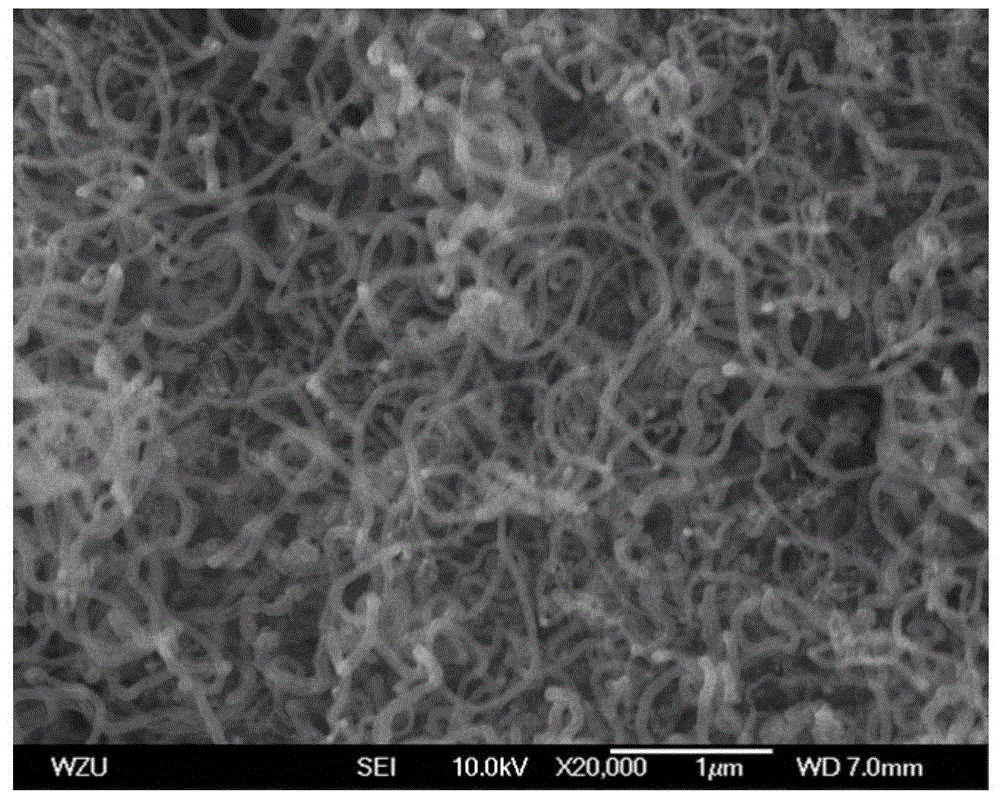

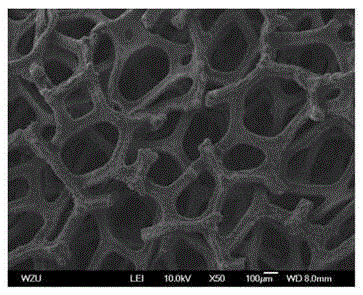

The invention discloses a method for directly growing a carbon nanotube on a foamed nickel substrate so as to prepare battery electrodes. The method comprises the following steps: (1) performing chemical and ultrasonic cleaning by taking foamed nickel as a catalysis and substrate material for chemical vapor deposition reaction of the carbon nanotube; and (2) setting a CVD reaction device, directly performing the chemical vapor deposition growth of the carbon nanotube on the foamed nickel substrate in the CVD reaction device, the flow ratio between a hydrocarbon gas and a carrier gas is (10-40sccm):(100-400sccm) when the growth temperature is at 600-900DEG C, the growth pressure is at 1-760Torr, and the growth time lasts for 1-30min. The method has the advantages that the significant role in enhancing the performance of a battery device can be achieved, the specific surface area and the electrochemical activity of the CNT-foamed nickel substrate can be obviously improved, and the cycle life of the CNT-foamed nickel substrate nickel-hydrogen battery can be obviously prolonged.

Owner:WENZHOU UNIVERSITY

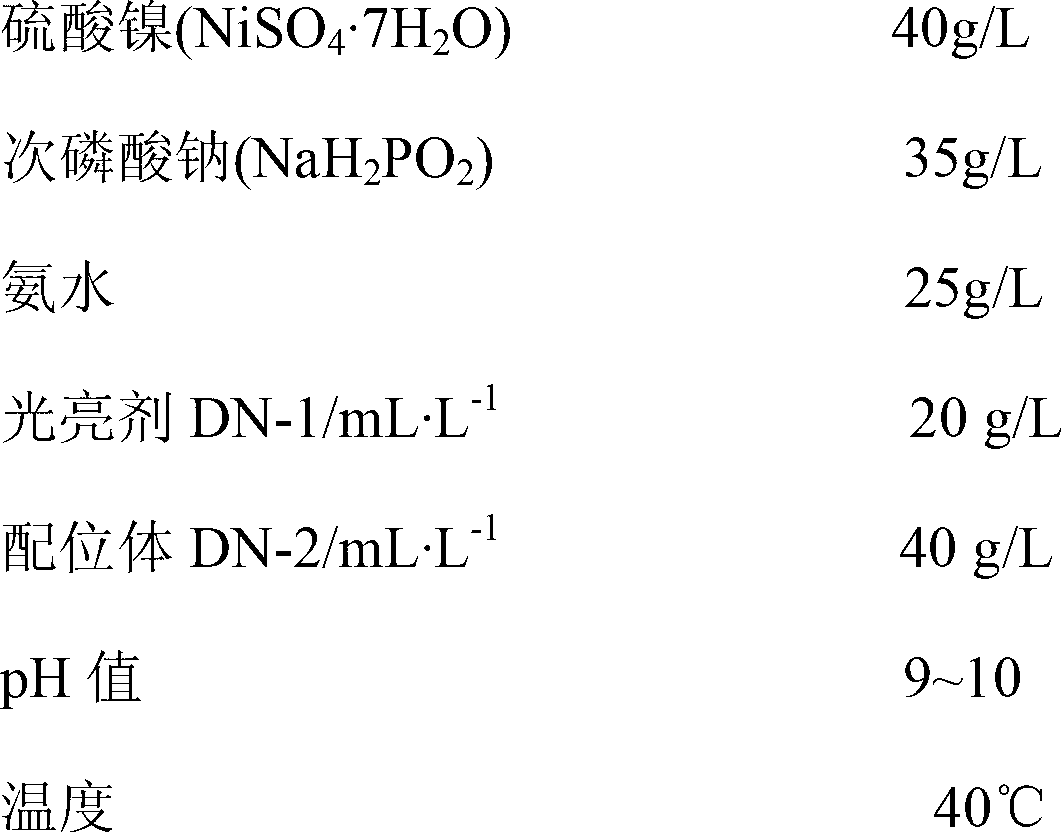

Three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and preparation method thereof

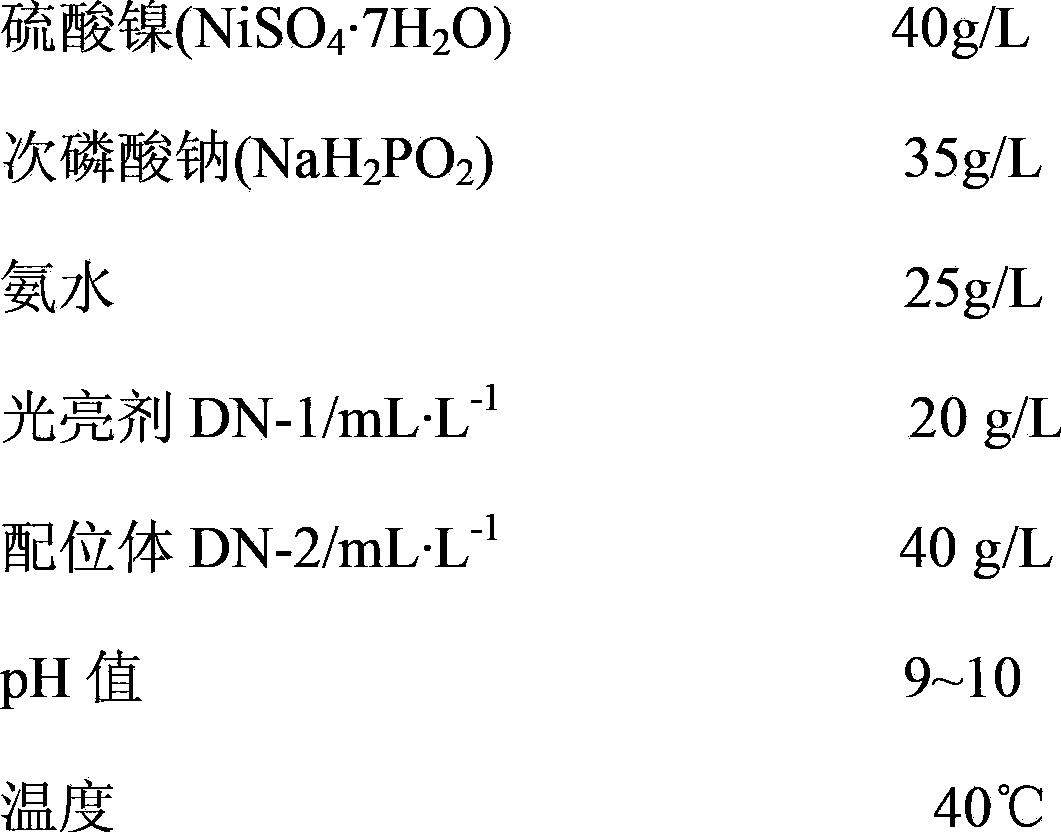

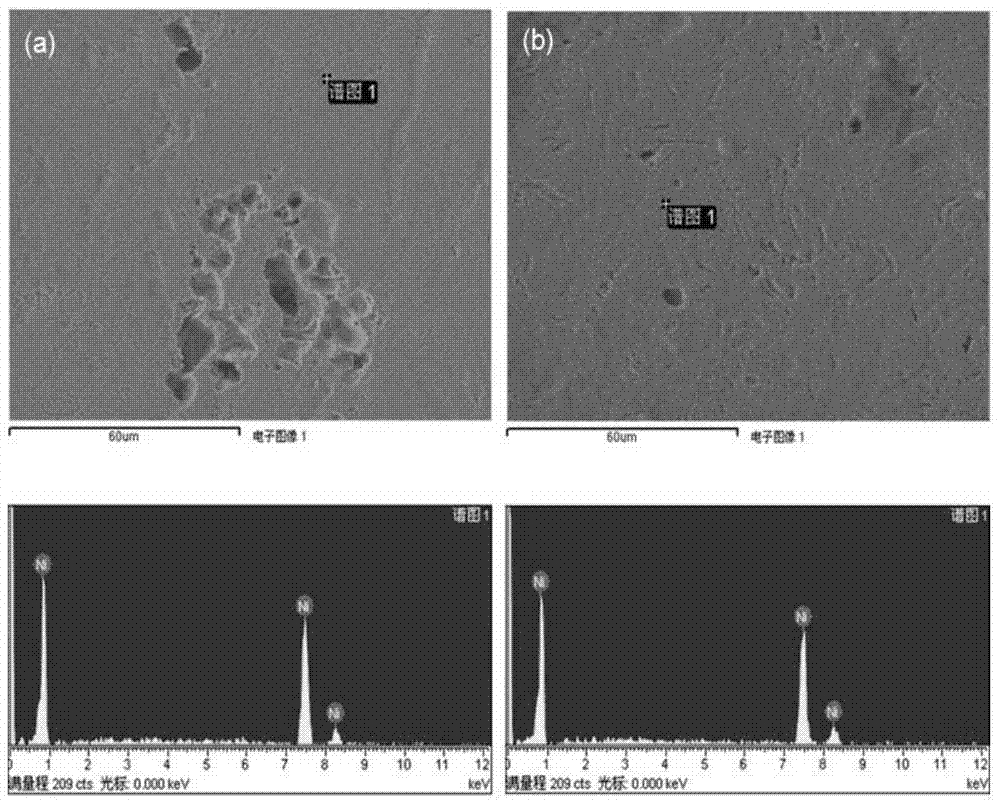

InactiveCN103022450AComplete structureResidue reductionElectrolytic coatingsCell electrodesTin platingCarbon nanotube

The invention discloses a three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and a preparation method thereof. The preparation method of the three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode comprises the following steps: firstly, chemically plating carbon nanotubes with a nickel layer of a certain thickness; secondly, uniformly dispersing nickle-plated CNTs (carbon nanotubes) into a tin-plating solution; thirdly, taking foamy copper as a current collector (a plating substrate), sequentially compositely plating a CU-(CNTs-Ni) composite plating layer with the thickness of 1-3 microns, and plating an Sn-(CNTs-Ni) composite plating layer with the thickness of 0.1-3 Mum; and finally, performing thermal treatment to obtain a three-dimensional composite network alloy electrode. The alloy negative electrode has the first discharge specific capacity of 620mAh / g, and after 200cycles, the specific capacity is attenuated by only 3-5%; the preparation method is simple in process; and the prepared alloy negative electrode is excellent in performance and is applicable to large-scale industrial production.

Owner:XIANGTAN UNIV

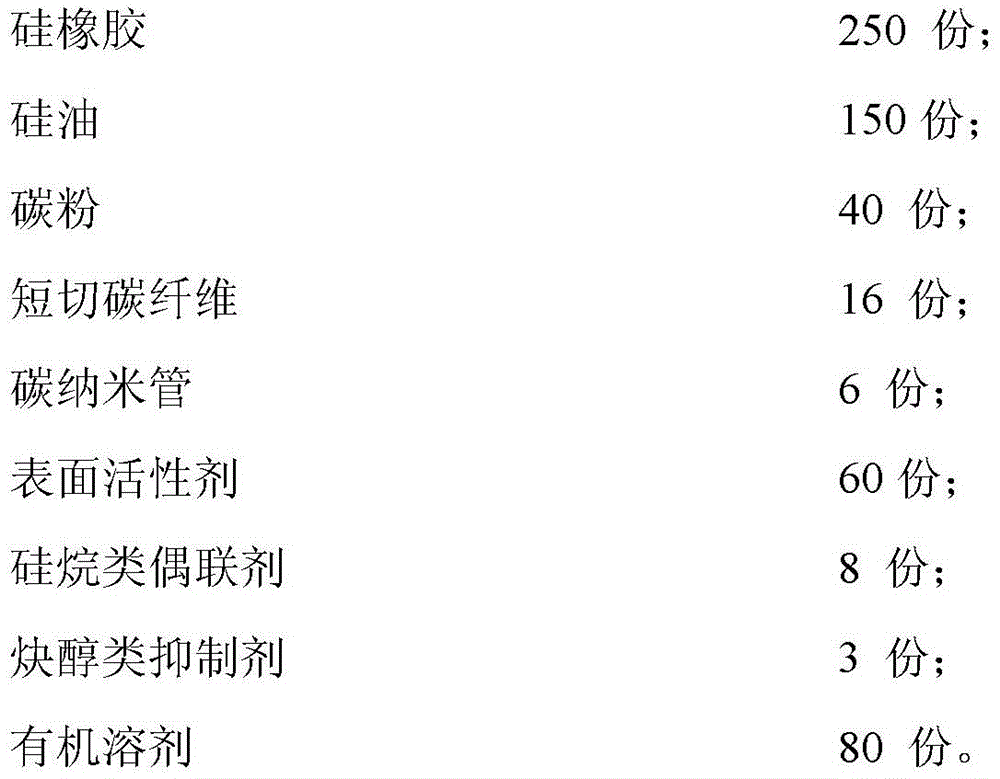

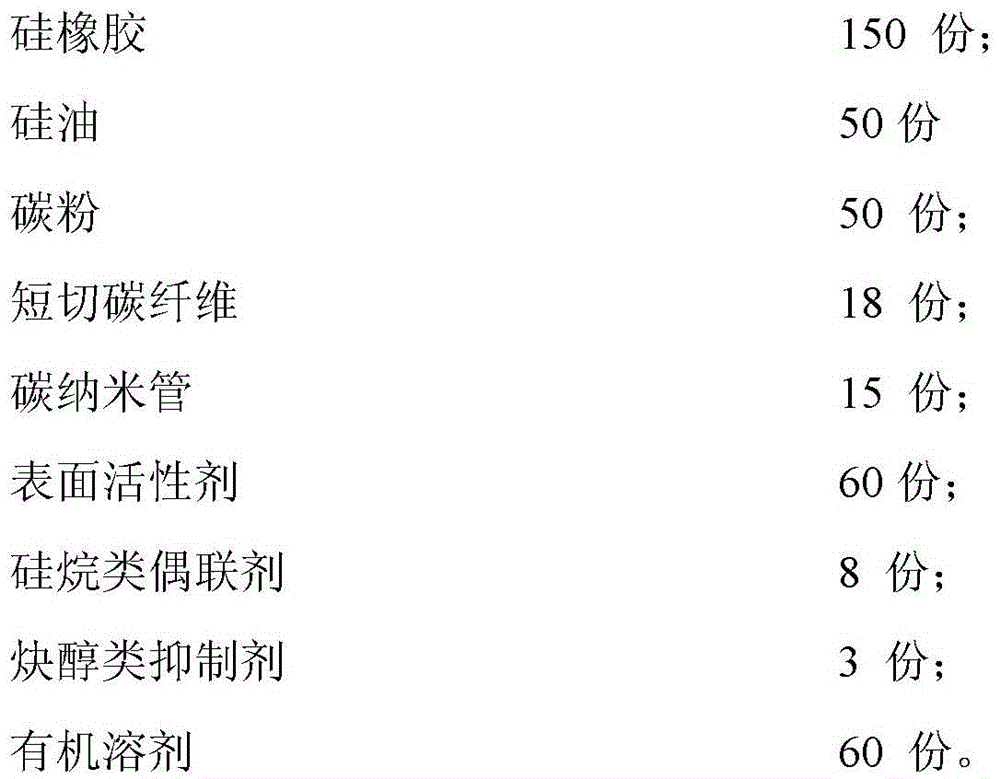

High-thermal-conductivity organic silicon adhesive doped with multiple carbon materials and preparation method of adhesive

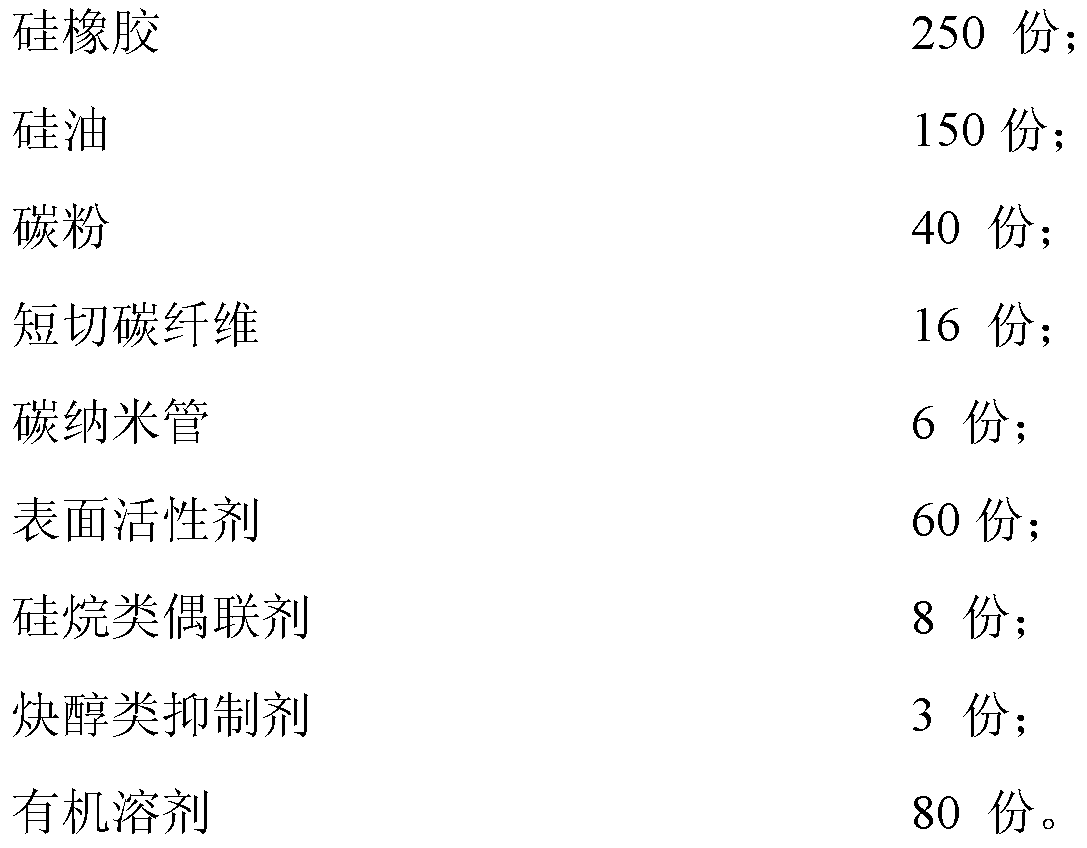

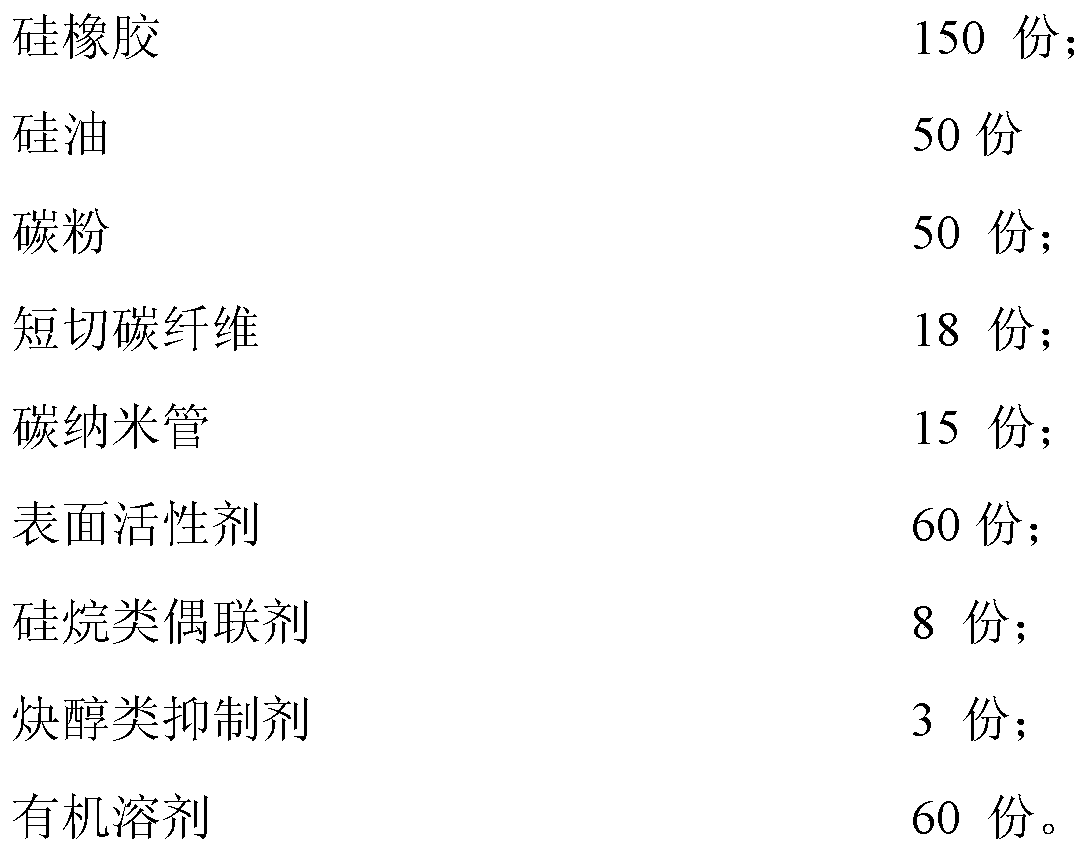

ActiveCN105419724AImprove thermal conductivityImprove stabilityNon-macromolecular adhesive additivesFiberAdhesive

The invention discloses a high-thermal-conductivity organic silicon adhesive doped with multiple carbon materials and a preparation method of the adhesive, relates to an organic silicon adhesive and a preparation method thereof, and aims to solve the problem that an existing organic silicon adhesive is lower in heat conductivity coefficient. The adhesive is prepared from silicone rubber, silicone oil, carbon powder, short carbon fiber, carbon nano tubes, a surfactant, a silane coupling agent, an alkynol inhibitor and an organic solvent. The method comprises the steps of 1, weighing the silicone rubber, the silicone oil, the carbon powder, the short carbon fiber, the carbon nano tubes, the surfactant, the silane coupling agent, the alkynol inhibitor and the organic solvent; 2, chemically grafting the carbon nano tubes to the short carbon fiber; 3, performing surface treatment on a thermally conductive filler; 4, mixing the silicone rubber and the silicone oil evenly by an open mill, then adding the thermally conductive filler obtained in step 3 via a three-roller grinder, mixing evenly, and then mixing the silane coupling agent, the alkynol inhibitor and the organic solvent, thus obtaining the high-thermal-conductivity organic silicon adhesive. The method is used for preparing the organic silicon adhesive.

Owner:HARBIN INST OF TECH

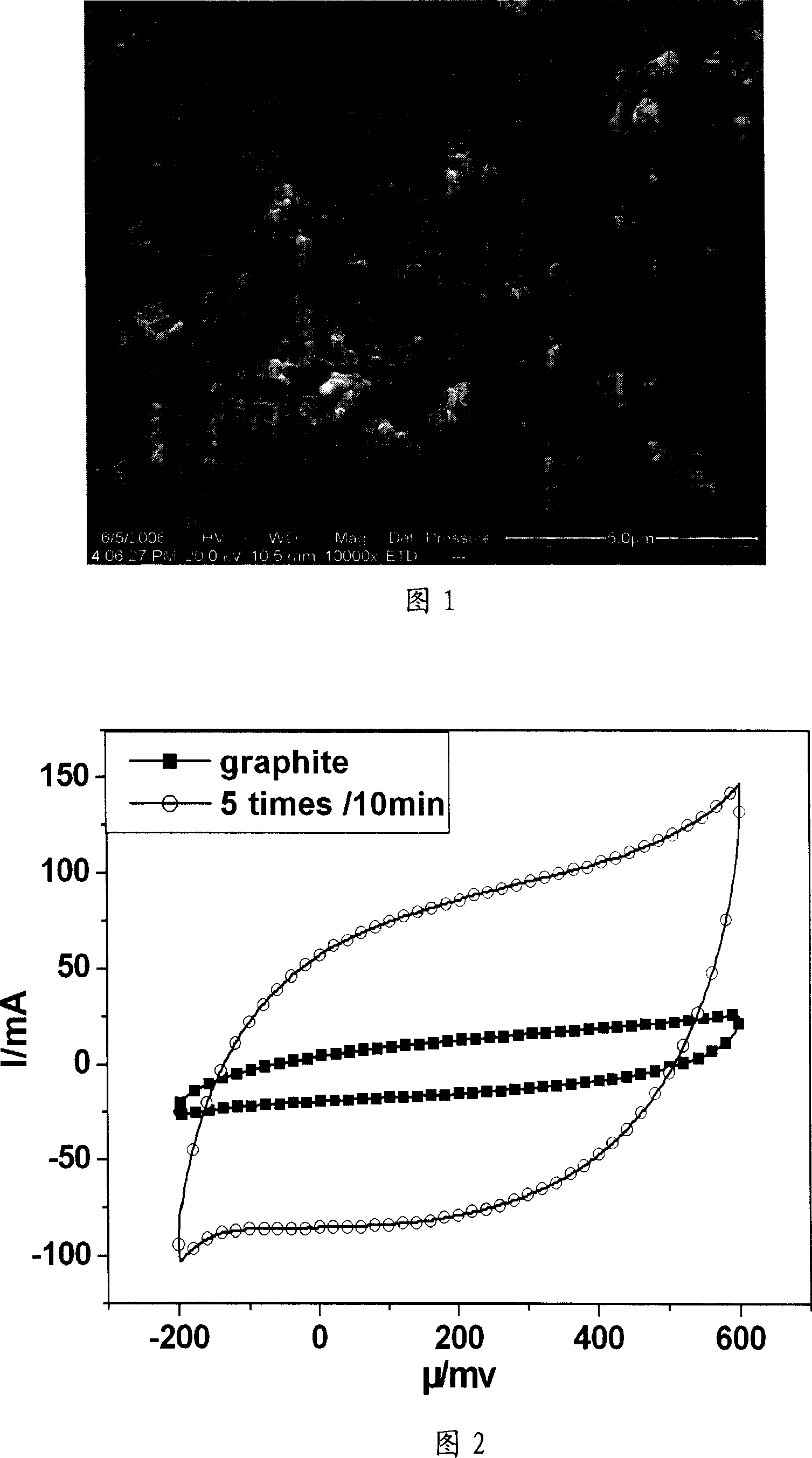

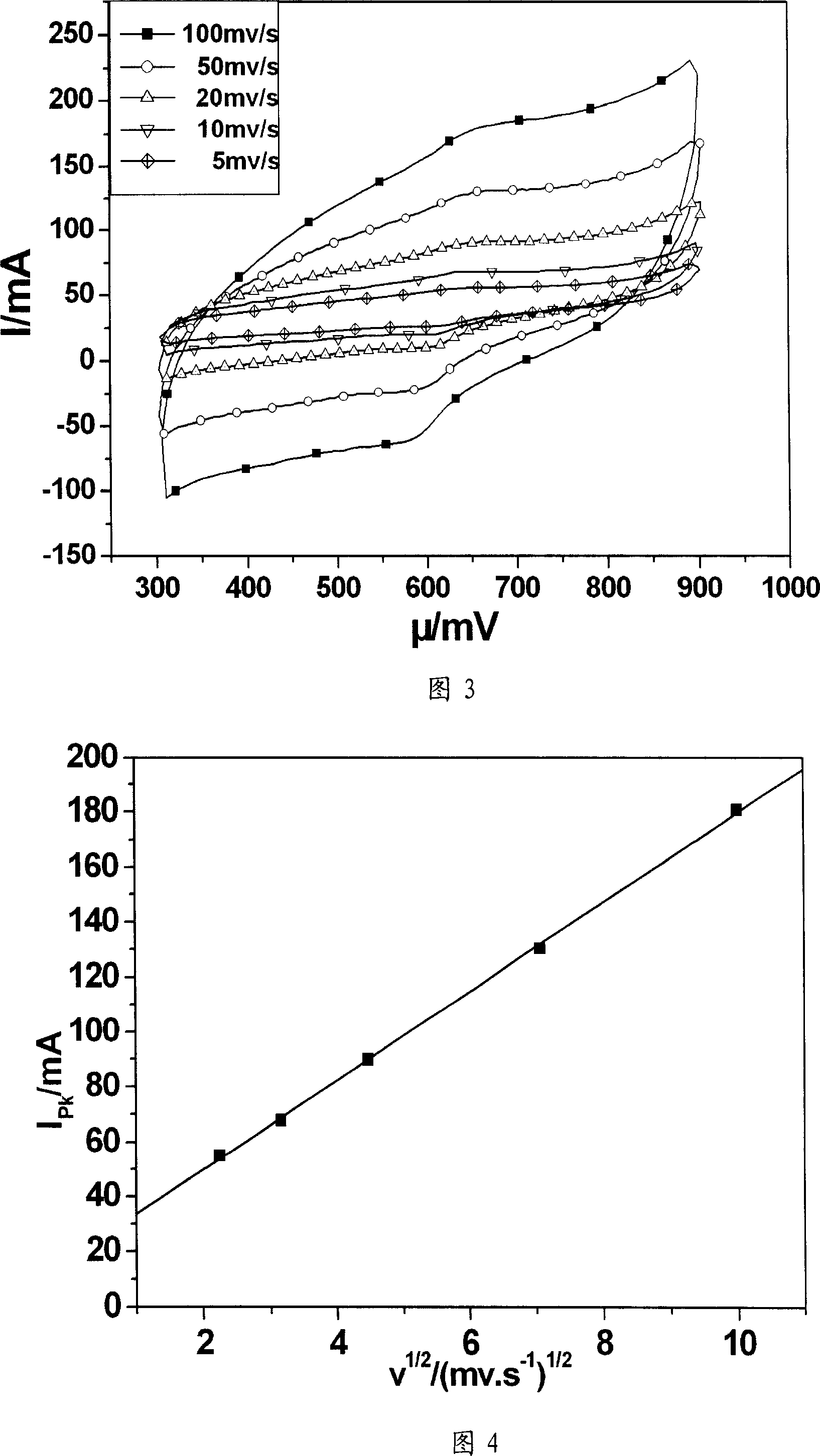

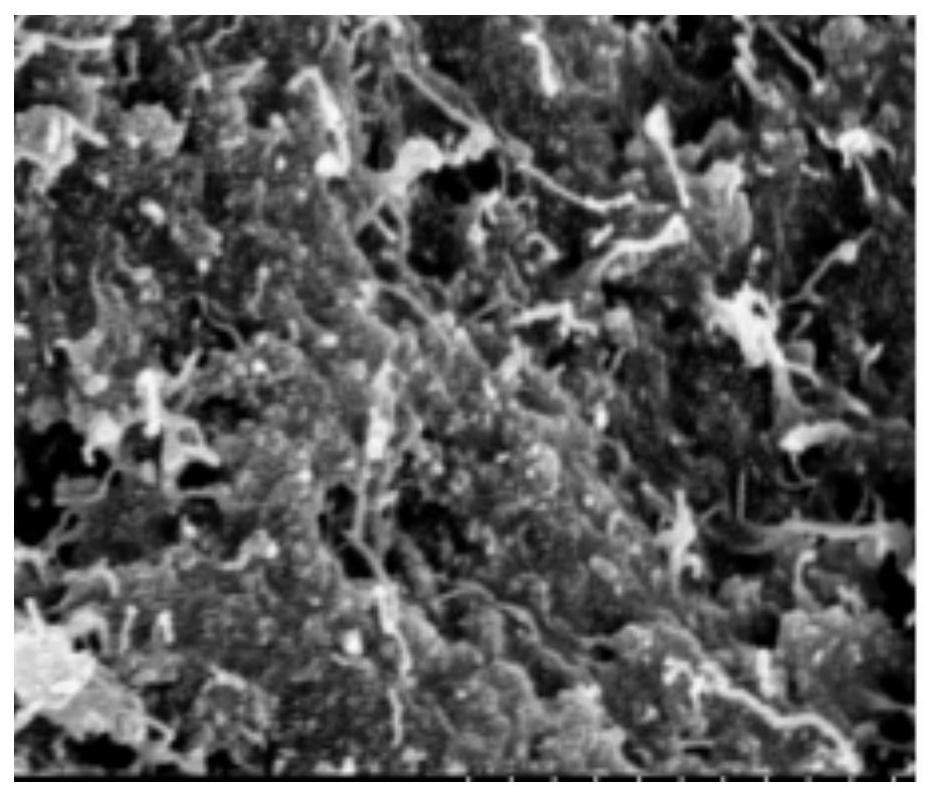

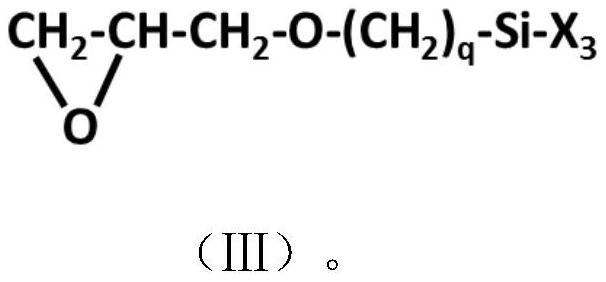

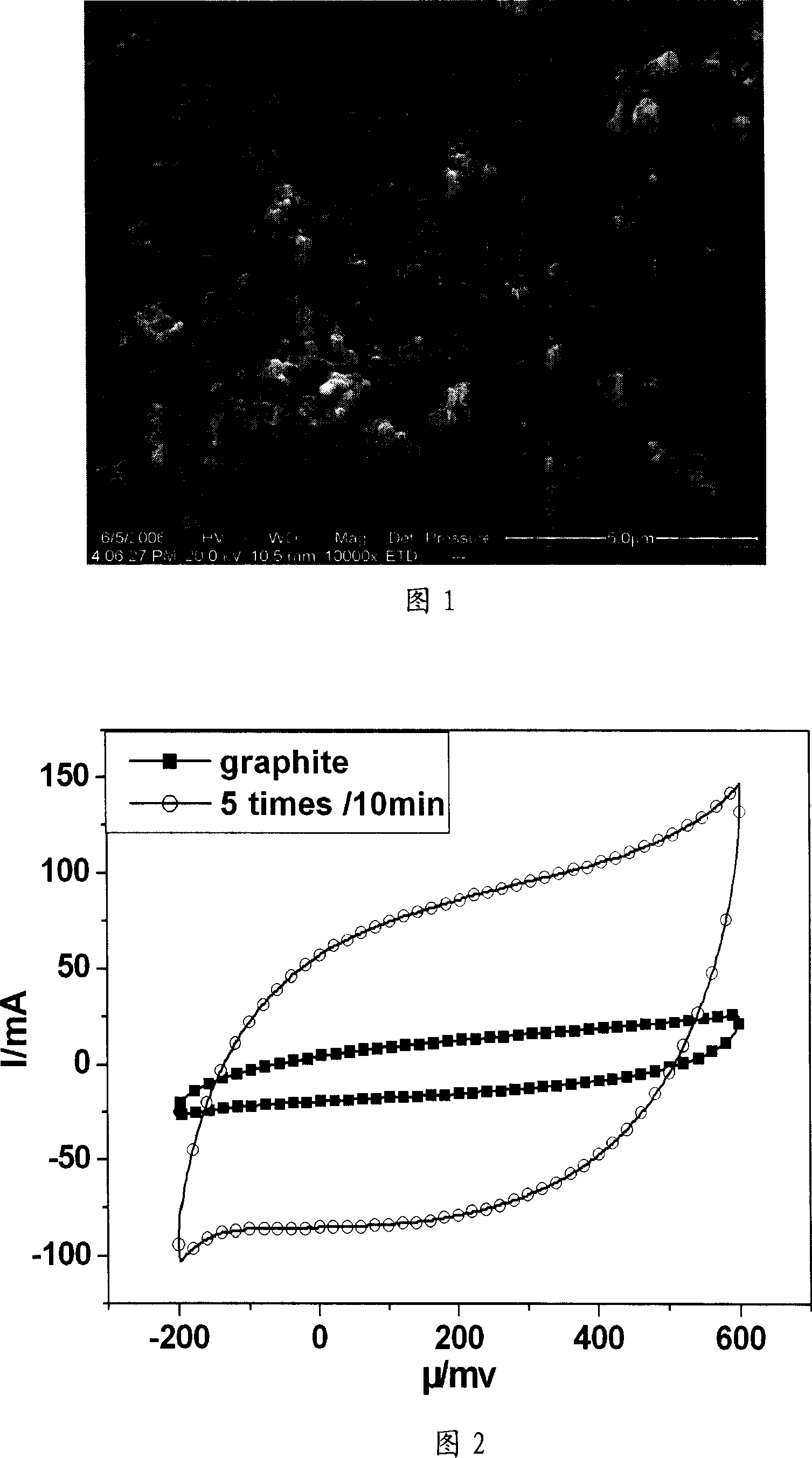

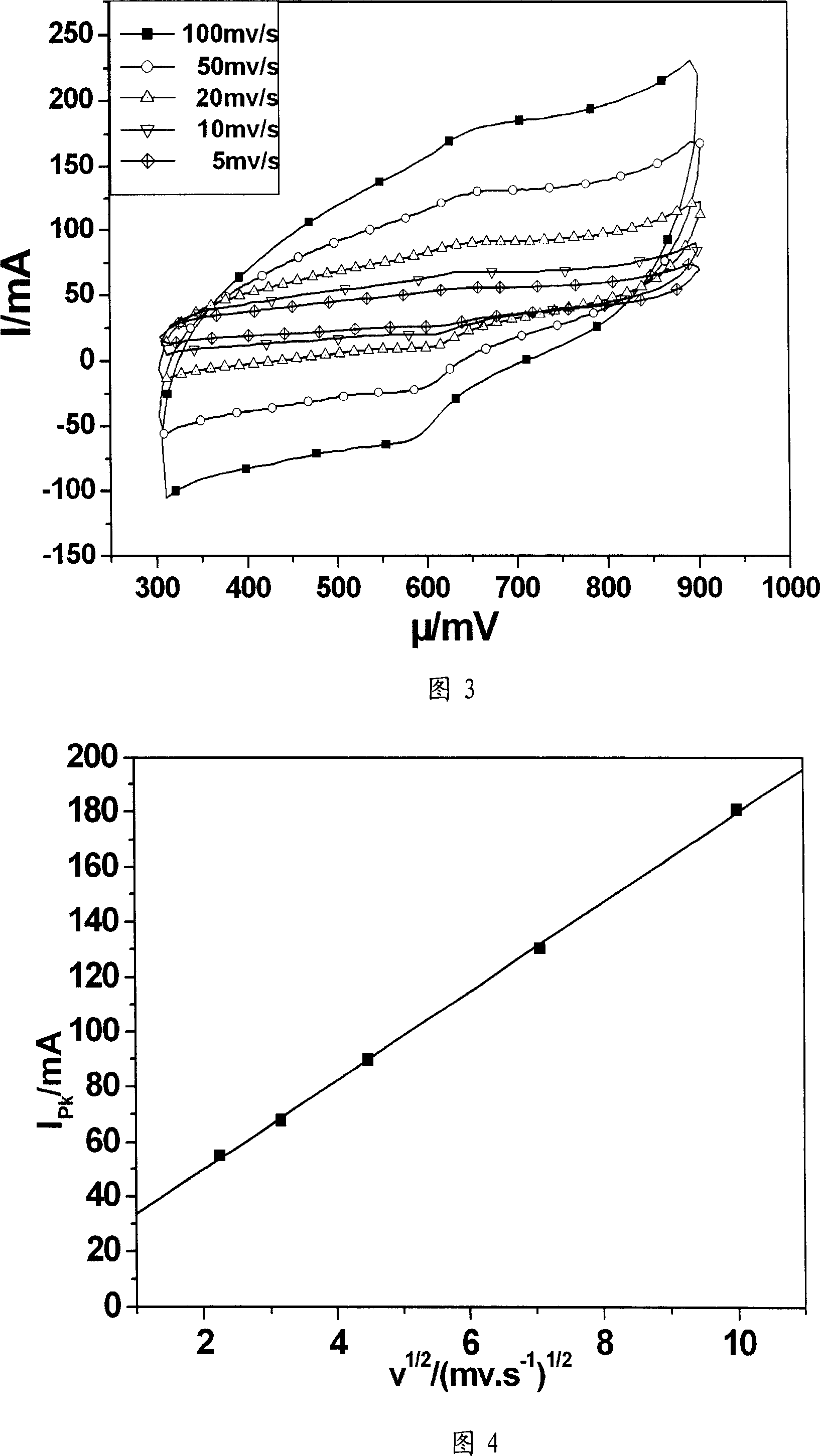

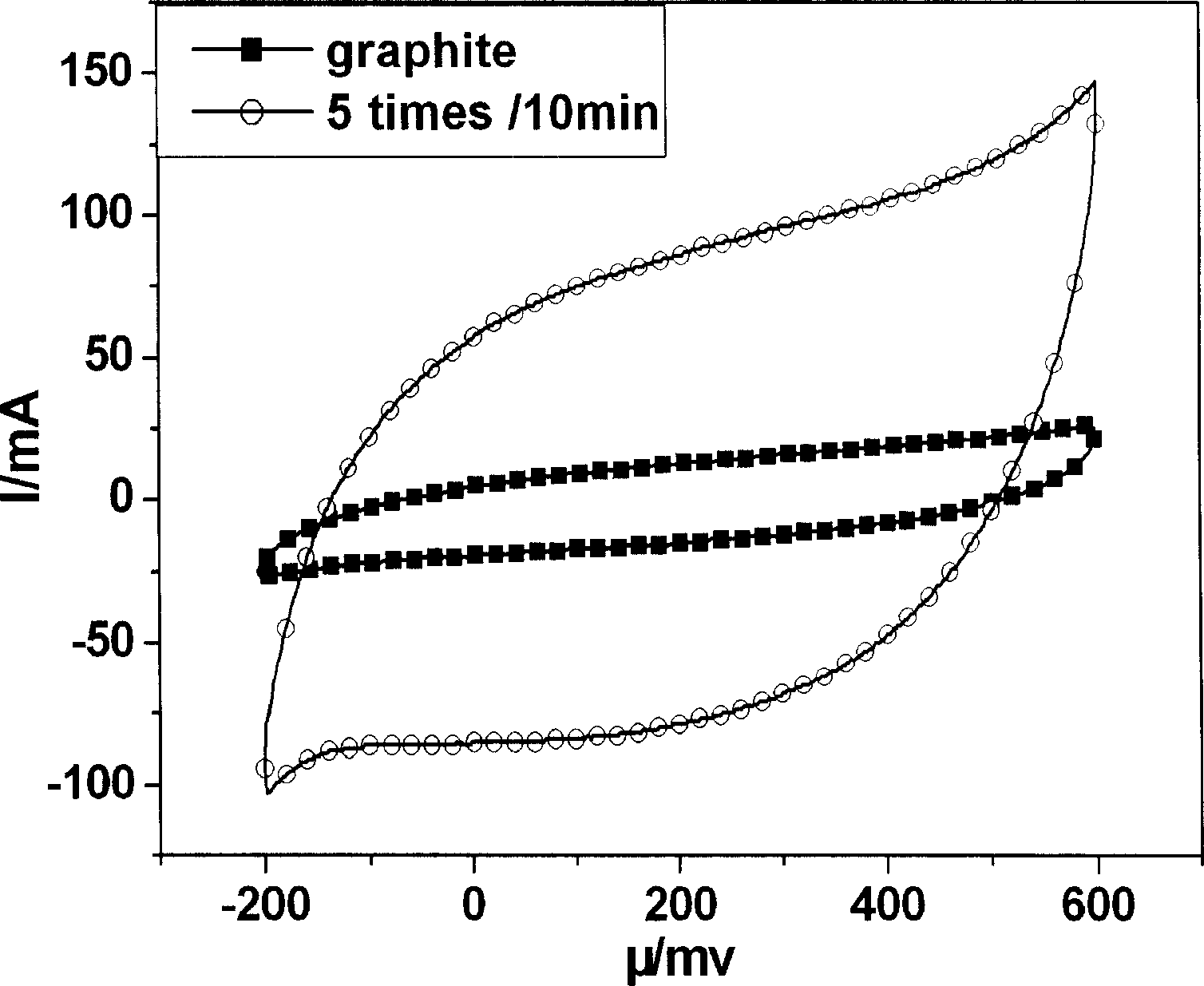

Method for preparing in-situ growing carbon nano tube chemical decoration electrode

InactiveCN1987443AIncrease response currentHigh sensitivityMaterial electrochemical variablesCarbon nanotubeElectrochemistry

Using immersion method, magnetron sputtering method or electroplating method prepares catalyst in use for Nano carbon tubes to be developed attached to surface or shallow layer on surface of solid electrode. Then, carbon source are developed to Nano carbon tubes in situ of electrode catalyst attached to. Advantages are: good electrochemistry performance and detection performance of electrode chemical modified by Nano carbon tubes.

Owner:SOUTHWEST JIAOTONG UNIV

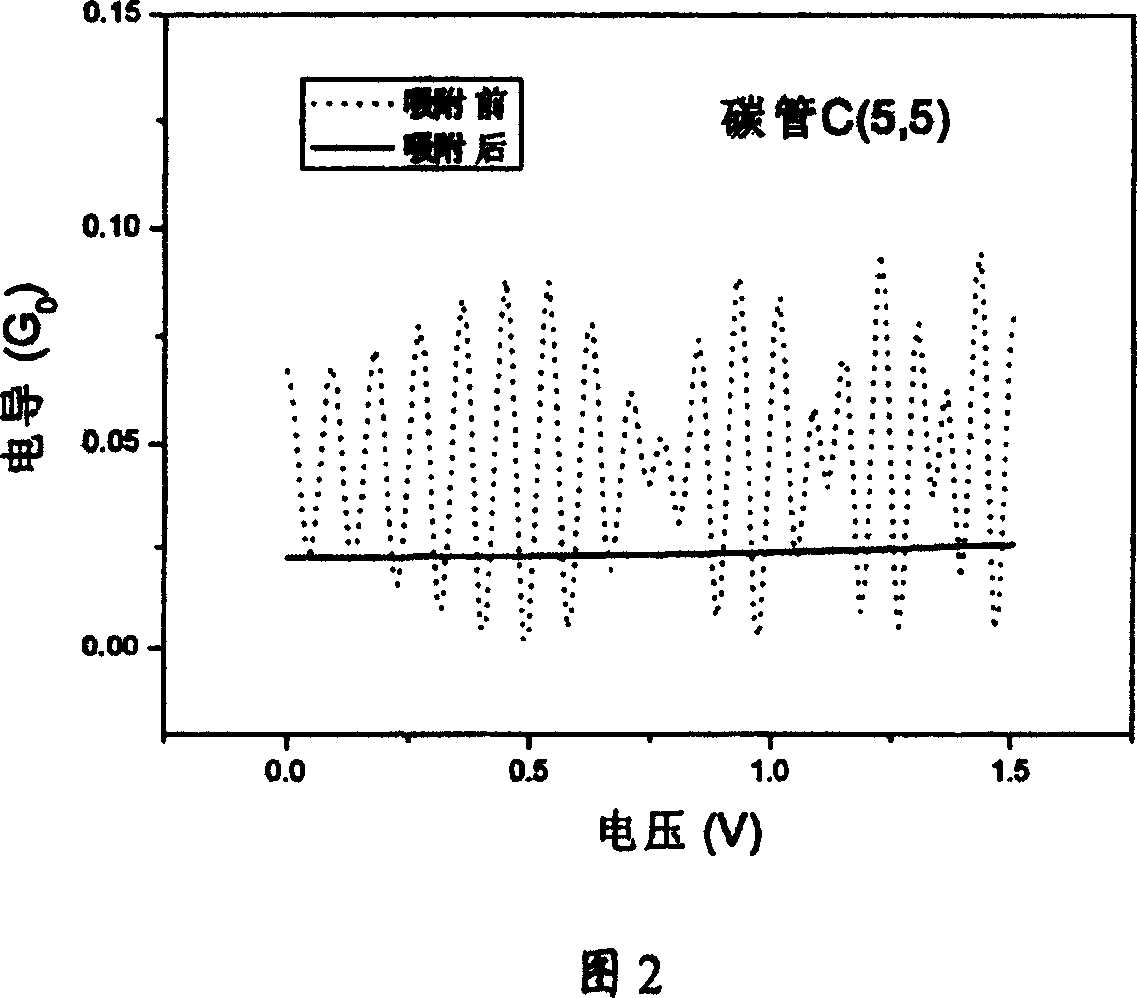

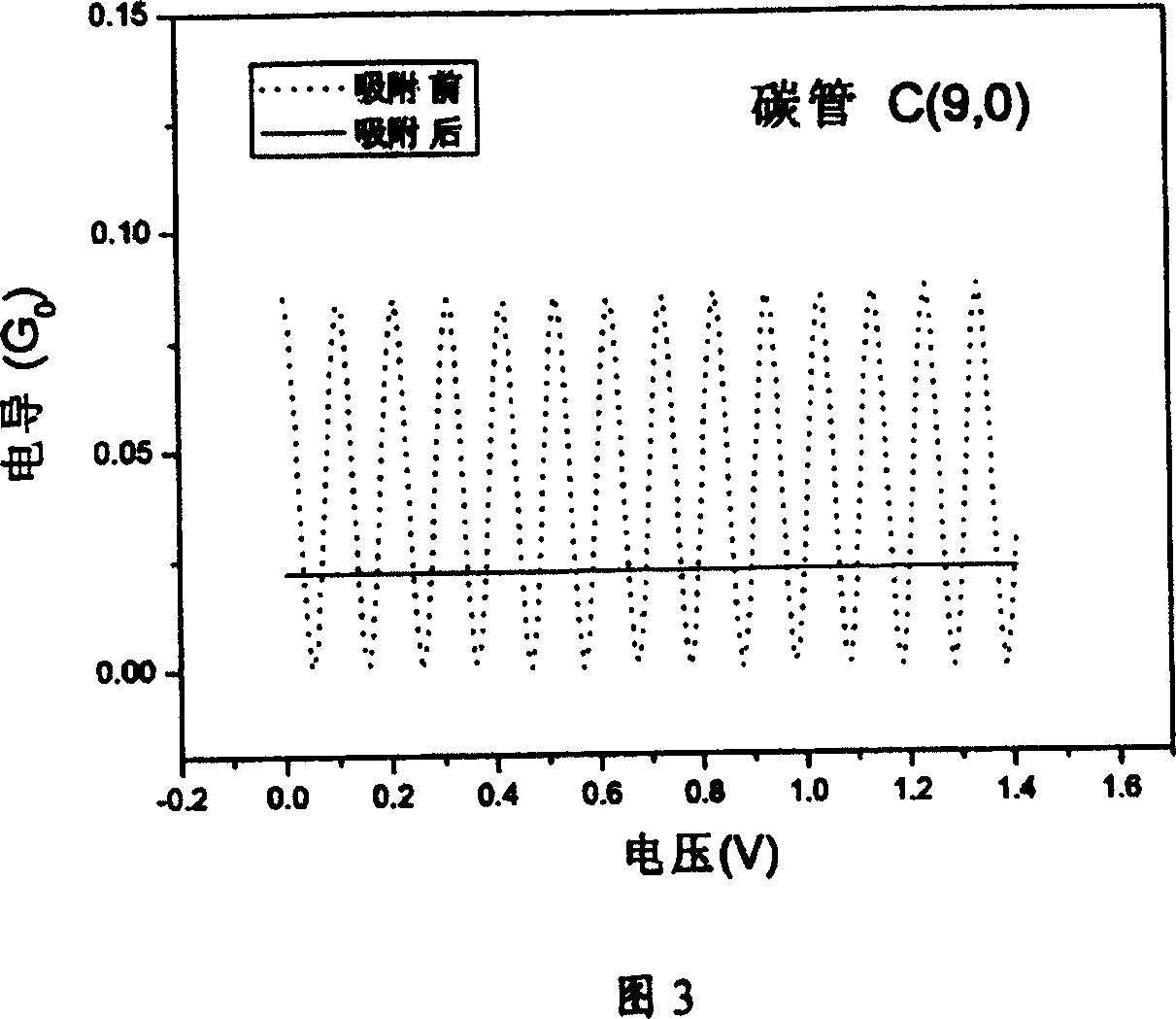

Process for derivatizing carbon nanotubes with diazonium species and compositions thereof

The present invention specifically describes a new method for chemical modification of carbon nanotubes. Such methods involve the derivatization of multiwalled and single-walled carbon nanotubes, including small-diameter (about 0.7 nm) single-walled carbon nanotubes derivatized with diazo compounds. This method allows various organic compounds to be chemically attached to the sidewalls and ports of carbon nanotubes. Such chemically modified carbon nanotubes are used in polymer composites, molecular electronics and sensor elements. Derivatization methods include electrochemically induced reactions, thermally induced reactions (via in situ or pre-generated diazo compounds) and photochemically induced reactions. Derivatization significantly changes the spectral properties of the nanotubes. The functionality is estimated to be approximately one functional moiety for every 20-30 carbon atoms in the nanotube. Such electrochemical reduction methods can be used for site-selective chemical functionalization of nanotubes, and, after modification with appropriate chemical groups, derivatized nanotubes are chemically compatible with the polymer matrix, enabling nanotube properties (e.g., mechanical strength or conductivity) essentially translates into composite properties. Moreover, after modification of appropriate chemical genes, these chemical groups can be polymerized into polymers including carbon nanotubes.

Owner:RICE UNIV

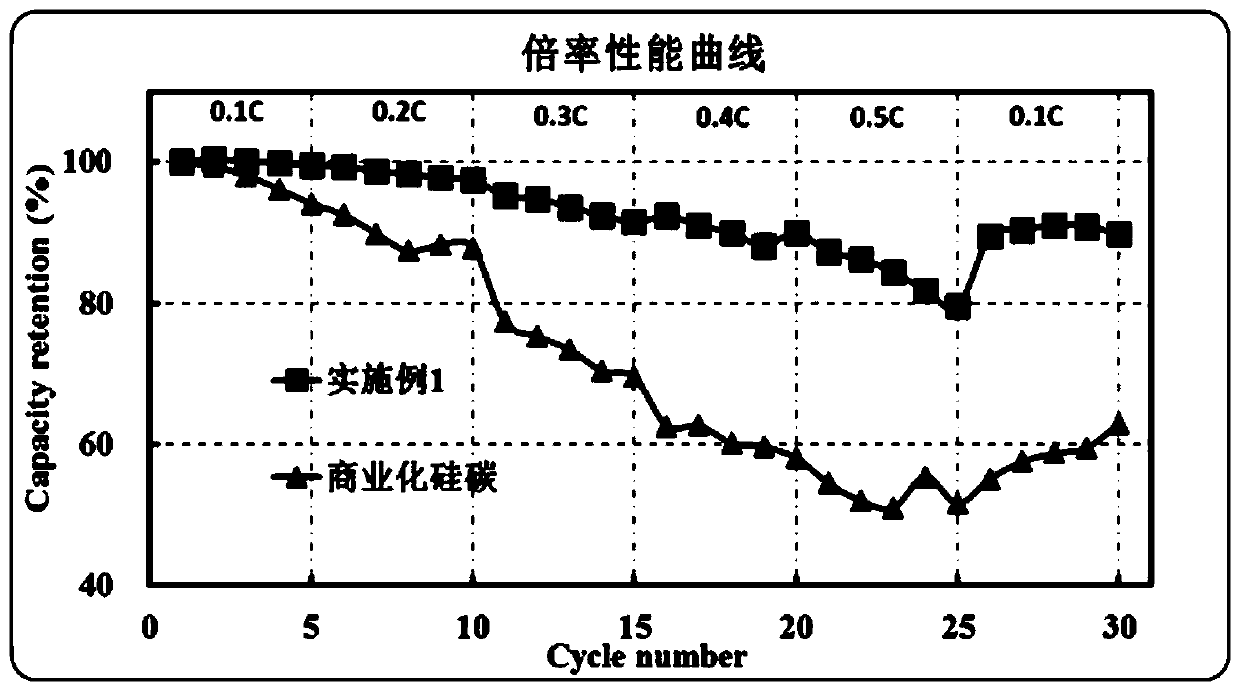

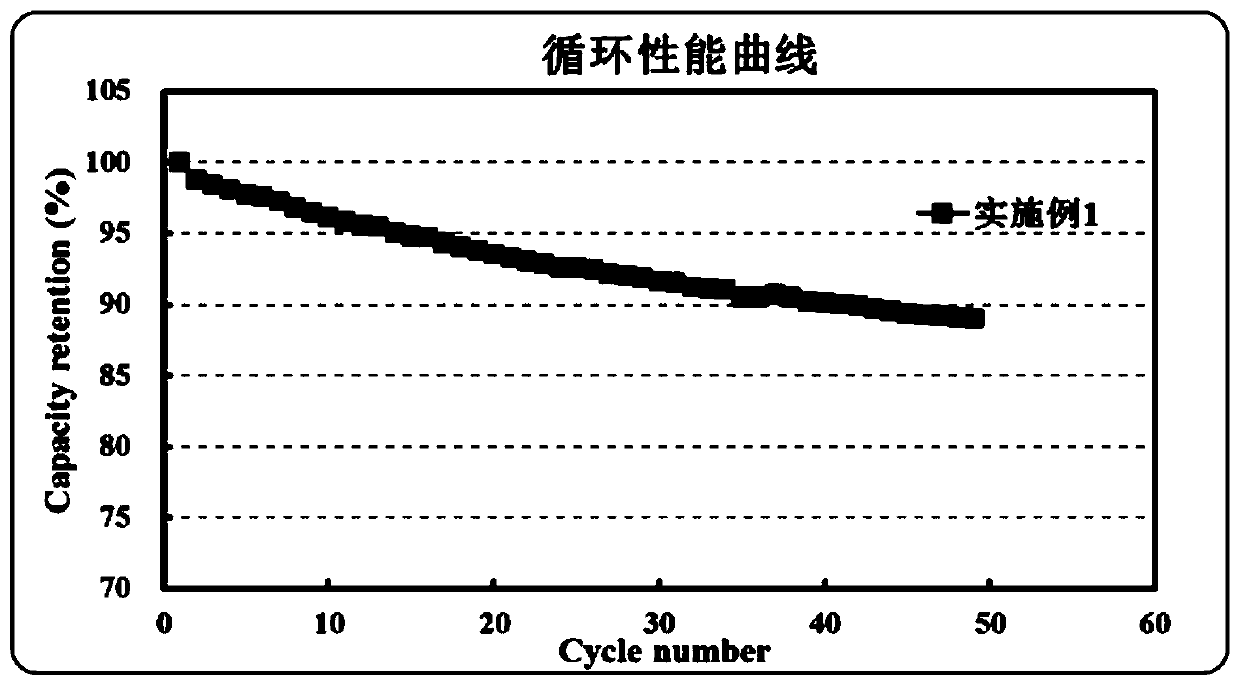

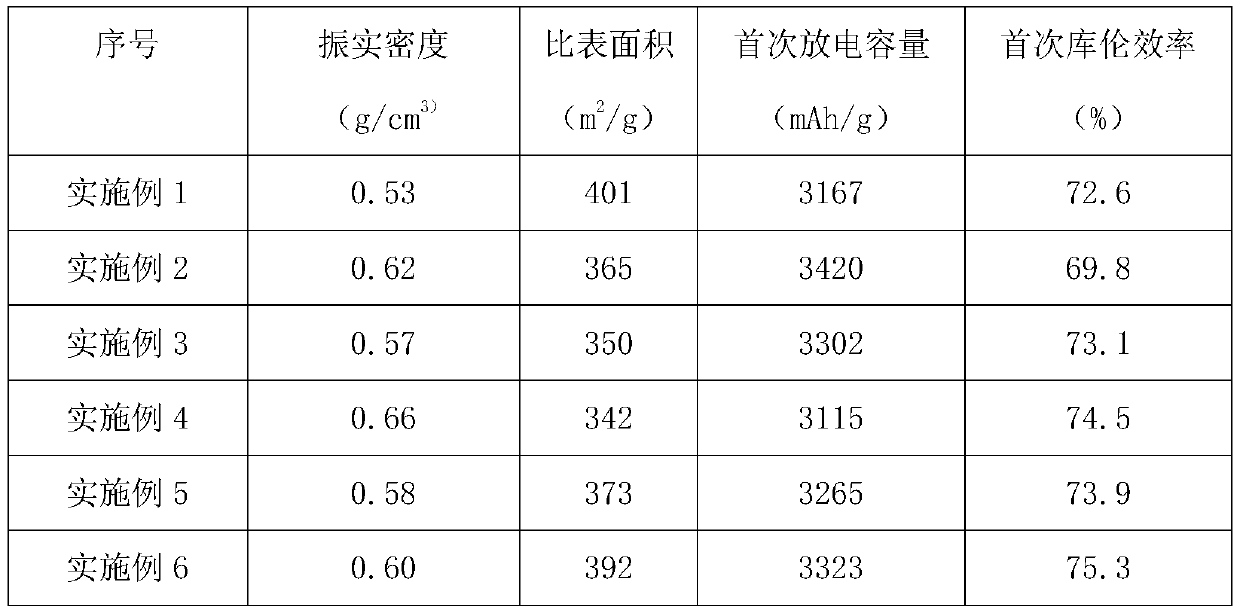

Preparation method of rate-type lithium ion battery silicon composite oxide material

InactiveCN110931729AImprove conductivityConductivity playSecondary cellsNegative electrodesSurface-active agentsLithium-ion battery

The invention discloses a preparation method of a rate-type lithium ion battery silicon composite oxide material, which comprises the following steps: (1) dispersion: preparing a carbon nanotube dispersion liquid from a surfactant and carbon nanotubes; (2) coating: adding tetraethoxysilane into the carbon nanotube dispersion liquid prepared in the step (1), stirring for reaction at room temperature, and drying to obtain a silicon dioxide coated carbon nanotube; (3) chemical deposition: preparing a carbon-coated silicon dioxide carbon nanotube from the silicon dioxide carbon nanotube obtained in the step (2) by adopting a chemical deposition method; and (4) gas-phase reaction: grinding the carbon-coated silicon dioxide carbon nanotube prepared in the step (3) and magnesium powder in proportion, heating, keeping constant temperature, cooling to room temperature, pickling, washing and drying to obtain the rate-type lithium ion battery silicon composite oxide material. The silicon composite oxide material prepared by the method has excellent rate capability and cycle performance, and the preparation process is simple and practical.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

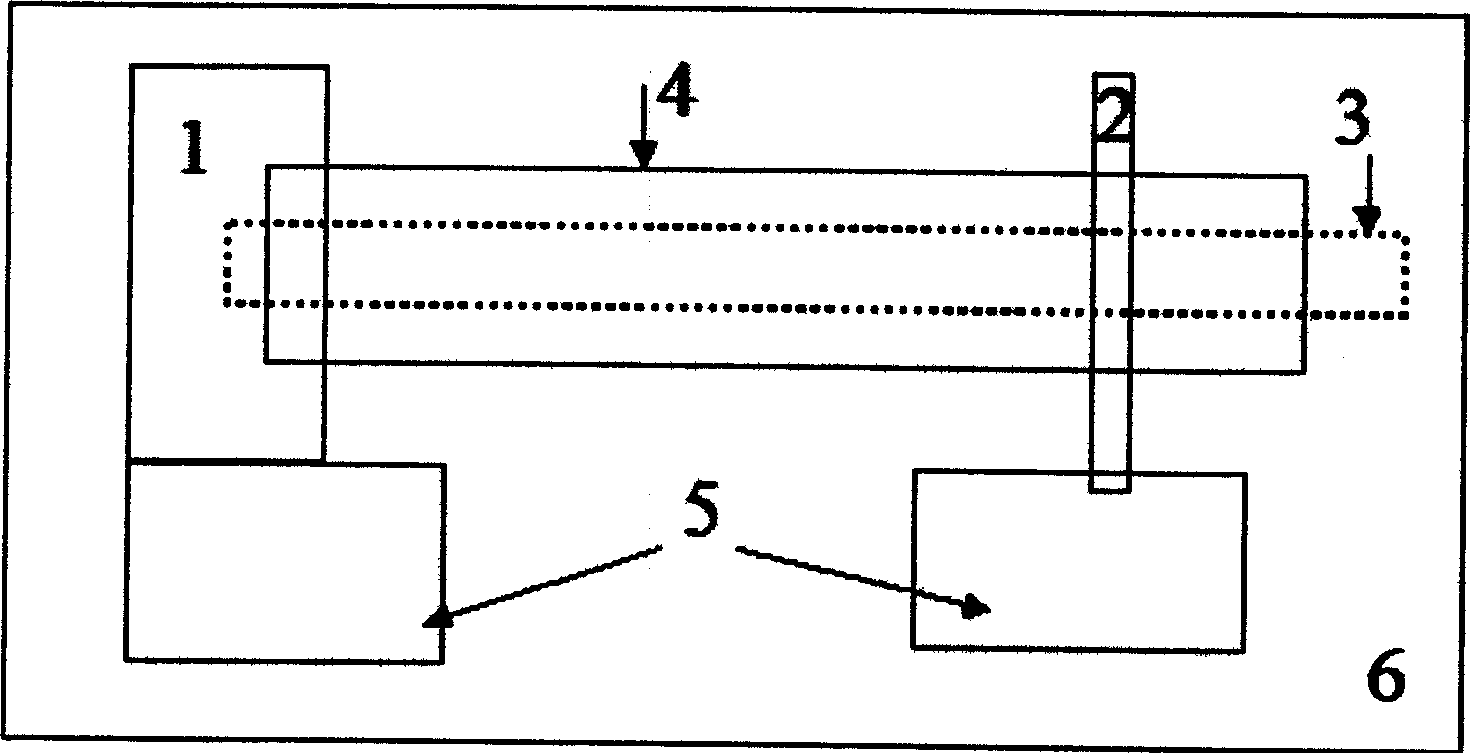

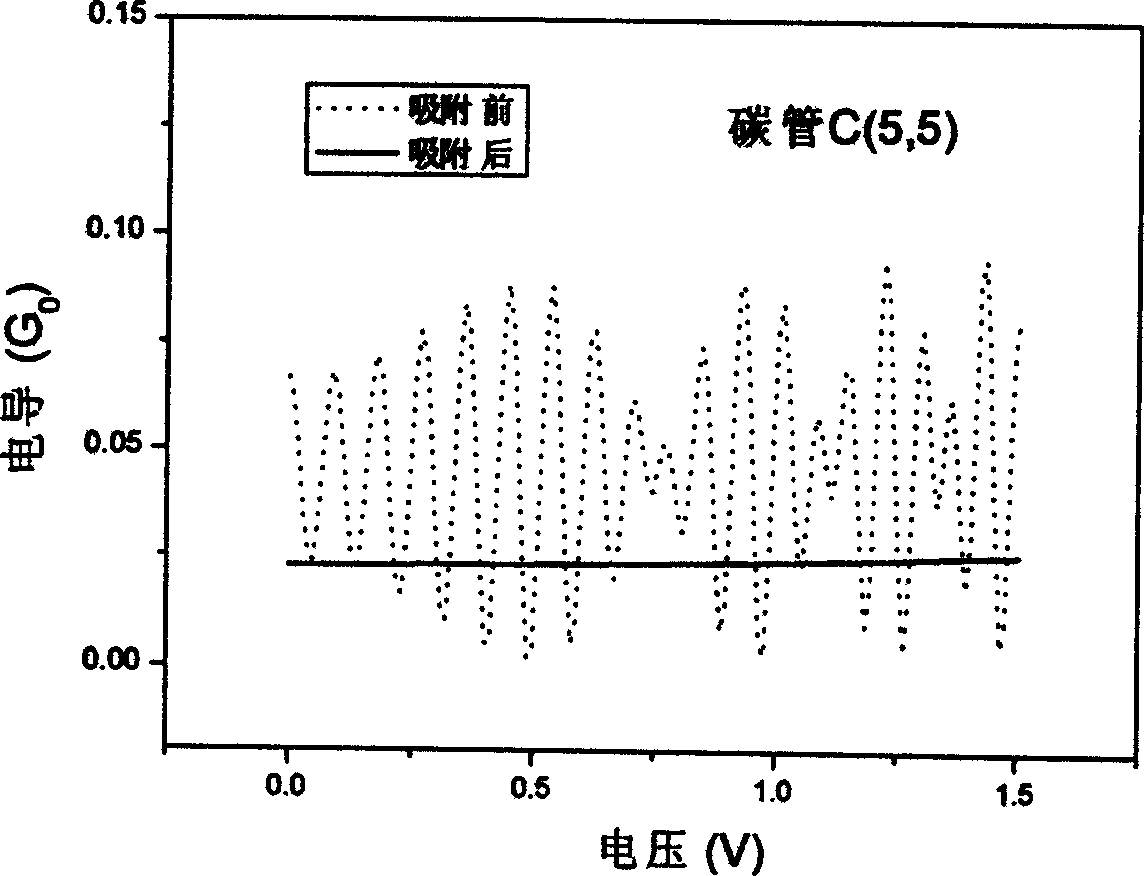

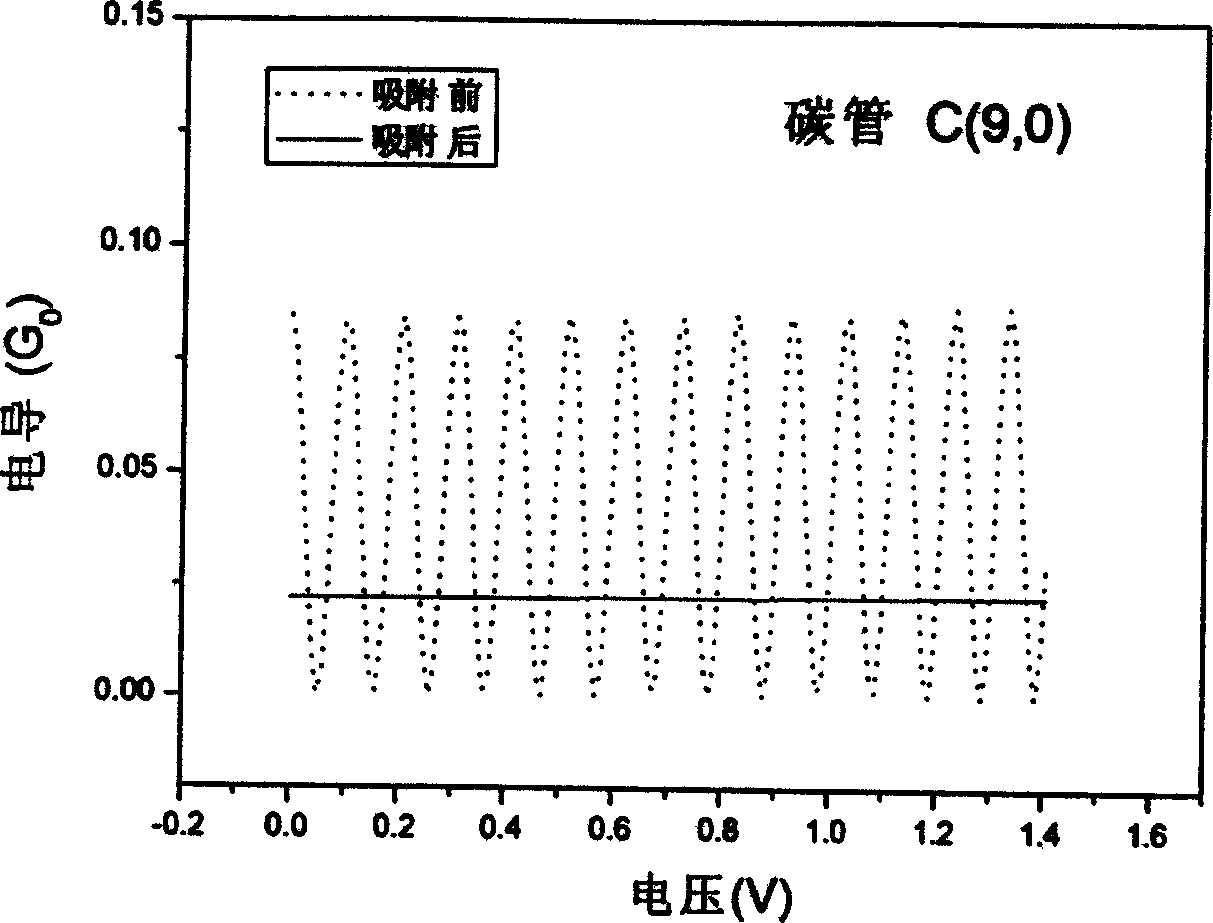

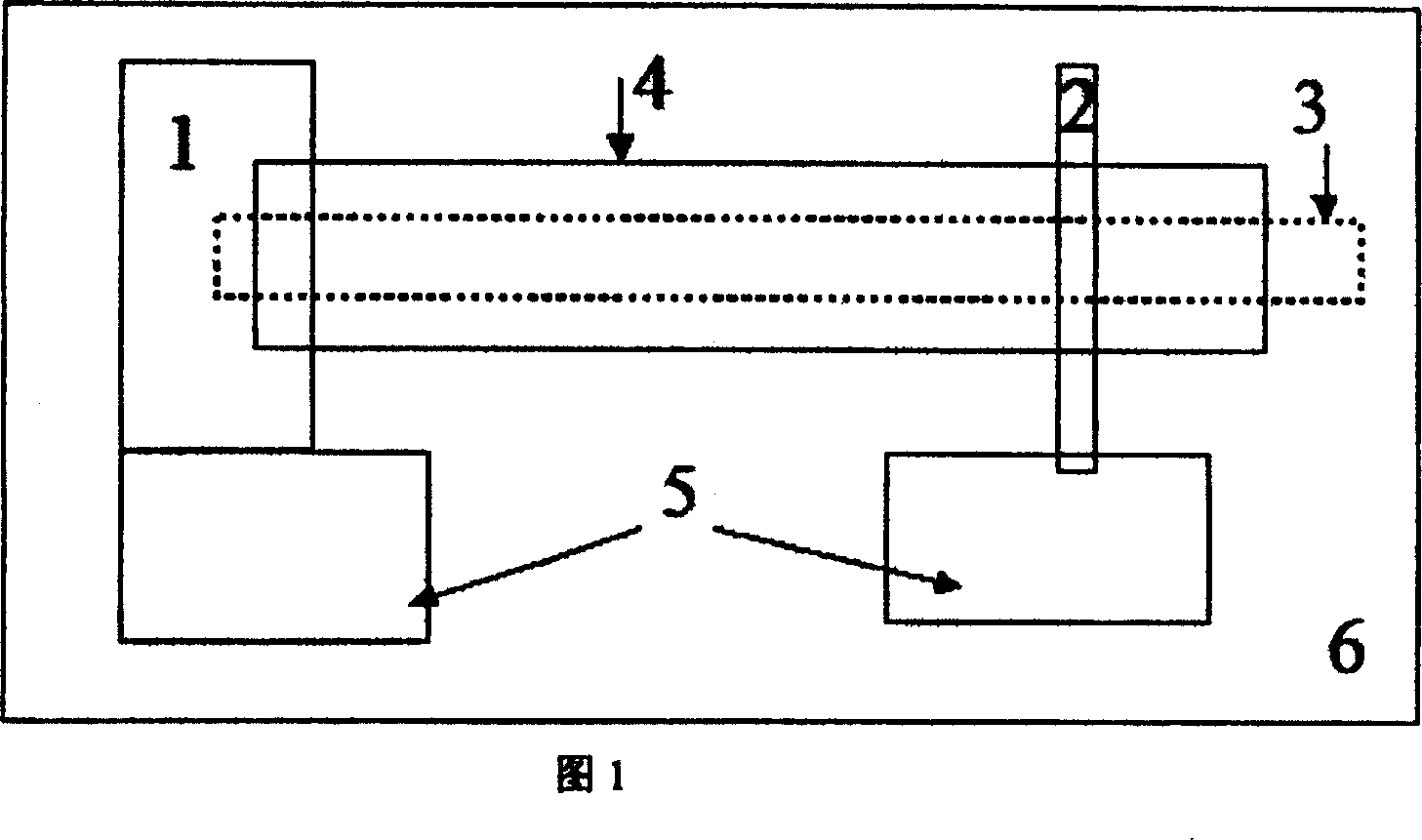

Carbon nanotube chemical molecular detection sensor and method for making same

InactiveCN1664570AHigh sensitivityRealize the recognition functionMaterial analysis using wave/particle radiationSolid-state devicesNanoscopic scaleCoherence length

The invention relates to a device and method for sensing detecting the chemistry molecule through the carbon nanometer tube. The device fits the single wall carbon nanometer tube on the substrate, on end of the tube deposits the base point electrode, deposits the coherent electrode on the place where the distance from the other end of the tube is the coherence length of the tube, the base point electrode and the coherent electrode are connected with the detector through the external electrode set on the substrate or connected directly, the tube has the protective coating while the unsupported is exposed as the sensing probe. The making method is: setting the single wall carbon nanometer tube scatter on the insulated substrate, preparing metal base point electrode in one end, depositing metal coherence electrode and two metal external electrodes whose area is micron size in the other end, and connects with the base point electrode and coherence electrode individually.

Owner:UNIV OF SCI & TECH OF CHINA

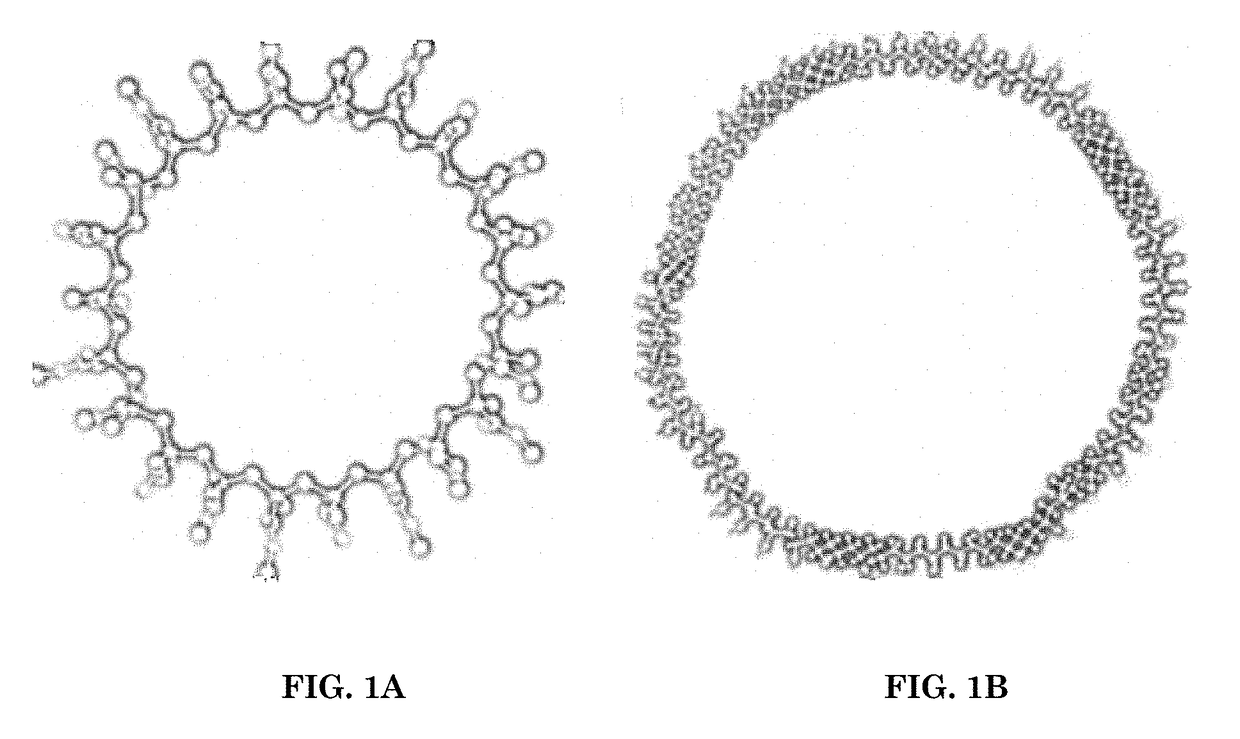

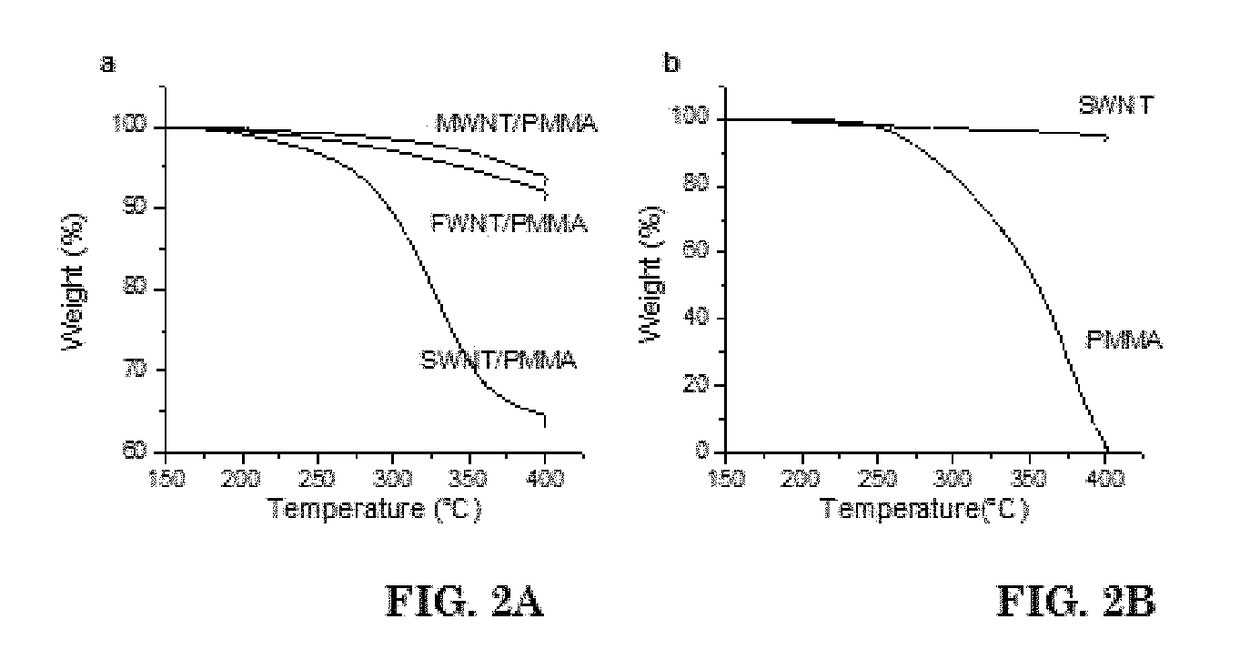

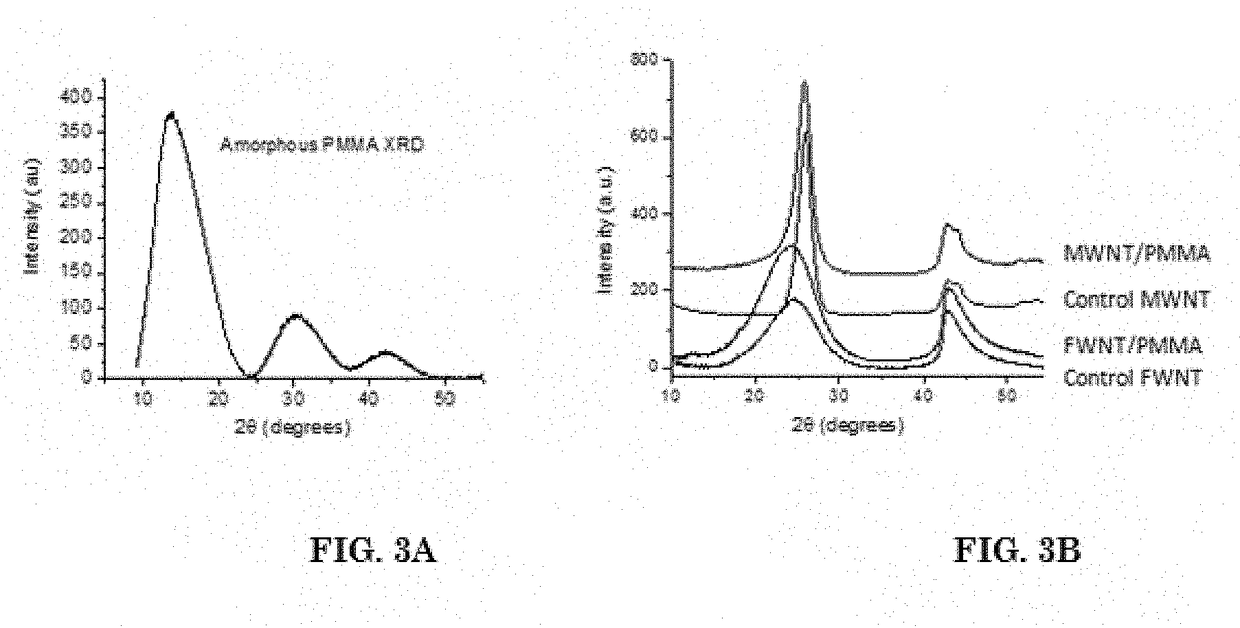

Ordered Wrapping of Poly(Methyl Methacrylate) on Single Wall Carbon Nanotubes

ActiveUS20170298208A1Fibre chemical featuresSingle-walled nanotubesPoly(methyl methacrylate)Mechanical property

Carbon nanotubes (CNTs) exhibit high electrical and thermal conductivity and good mechanical properties, making them suitable fillers for composites. Their effectiveness as a filler is affected by their state of aggregation. Novel ordered helical wrapping of poly (methyl methacrylate) (PMMA) has been achieved on single wall carbon nanotubes (SWNTs). This carbon nanotube composite not only thwarts CNT aggregation, but also may be successfully leveraged for applications such as electrical energy storage and mechanical reinforcement.

Owner:GEORGIA TECH RES CORP

Conductive material and manufacturing method thereof

ActiveUS20100305298A1Good chemical resistanceGood solvent resistanceLiquid surface applicatorsPlastic/resin/waxes insulatorsConductive coatingSurface resistivity

Disclosed is a method of manufacturing a conductive coating film having superior chemical resistance or solvent resistance and durability by chemically bonding a resin having an amine group (—NH2) with carbon nanotubes having a carboxyl group (—COOH). The conductive material having high bondability with carbon nanotubes and superior electrical properties includes carbon nanotubes uniformly contained therein, and thus has appropriate surface resistivity, and thereby can be used for antistatic, electrostatic dissipation and electromagnetic shielding purposes and in transparent or opaque electrodes depending on the resistivity value.

Owner:KOLON IND INC

Method for preparing battery electrode by directly growing carbon nanotubes on foamed nickel substrate

InactiveCN106784595AImprove bindingStrongly combinedAlkaline accumulator electrodesChemical vapor deposition coatingGas phaseCarbon nanotube

The invention provides a method for preparing a battery electrode by directly growing carbon nanotubes on a foamed nickel substrate. The method comprises the following steps of selecting foamed nickel as a catalytic and base material of a chemical vapor deposition reaction of carbon nanotubes, and performing chemical and ultrasonic cleaning on the foamed nickel substrate; setting a CVD reaction apparatus, performing direct chemical vapor deposition growth of the carbon nanotubes on the foamed nickel substrate in the CVD reaction apparatus, wherein when the growth temperature is 600-900 DEG C, the flow ratio of a hydrocarbon gas to a carrier gas is (10-40scmm) to (100-400sccm), the growth pressure is 1-760Torr, and the growth time is 1-30min. The method has the advantages as follows: a remarkable effect is played on improvement of performance of a battery device; the specific surface area and electrochemical activity of the CNT-foamed nickel substrate are greatly improved; and the cycle life of a nickel-metal hydride battery based on the CNT-foamed nickel substrate is highly prolonged.

Owner:CHANGDE LYRUN MATERIAL

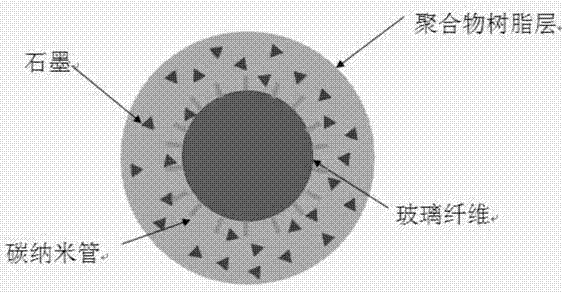

Preparation method of electronic cigarette oil-leading rope with carbon nanotube interface enhancement

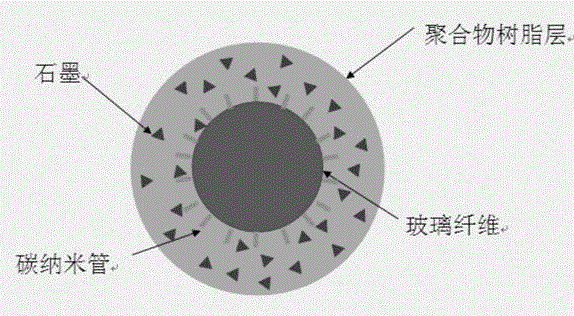

ActiveCN105544006ARaw materials are easy to getThe synthesis steps are simpleConjugated synthetic polymer artificial filamentsFiberGlass fiber

The invention discloses an electronic cigarette oil-leading rope with carbon nanotube interface enhancement, and a preparation method and a product thereof. The preparation method comprises the following steps of adopting glass fiber as a raw material, and using a carbon nanotube modified by mixed acid to modify the glass fiber, so that the carbon nanotube is chemically grafted on the glass fiber; processing through a coupling agent, performing blend spinning with resin to obtain glass fiber / polymer composite fiber with carbon nanotube interface enhancement, and interwinding to form the electronic cigarette oil-leading rope. The glass fiber / polymer composite fiber with carbon nanotube interface enhancement has favorable toughness and heat-transmission capacity, and the preparation process is simple and convenient. The electronic cigarette oil-leading rope provided by the invention not only well solves the problems of poor elasticity, fragility and easiness in breaking of the traditional oil-leading rope, meanwhile, the heat transmission capacity is also enhanced, and the phenomenon that an electronic cigarette element is damaged due to dry ashing is avoided.

Owner:CHINA TOBACCO GUANGXI IND

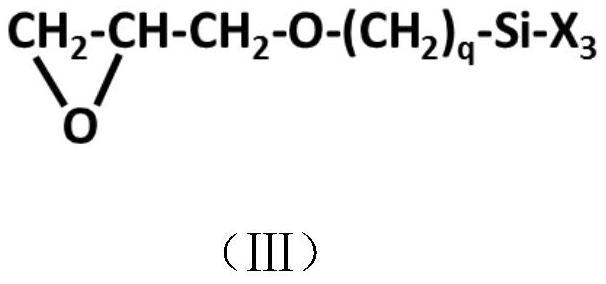

Conductive nylon masterbatch with graphene-carbon nanotube composite structure, and preparation method thereof

ActiveCN112029273AImprove mechanical propertiesAccurate and controllable loadMasterbatchPolymer science

The invention provides a conductive nylon master batch with a graphene carbon nanotube composite structure. The conductive nylon master batch is prepared by taking nylon as a carrier, carrying out grafting modification of carbon nanotubes and graphene, connecting the carbon nanotubes and graphene in a chemical bonding manner to form a composite structure and loading the composite structure on thenylon carrier. According to the conductive nylon master batch provided by the invention, firstly, surface grafting treatment is carried out on the carbon nanotubes and graphene, then ring-opening reaction is carried out on amino groups grafted on the surfaces of the carbon nanotubes and glycidyl ether oxy groups grafted on the surfaces of the graphene, the graphene and the carbon nanotubes are chemically combined, and finally, the conductive master batch is prepared. The carbon nanotube-graphene composite structure is well dispersed in a polymer, and meanwhile, graphene and the carbon nanotubes can be fully lapped, so that the synergistic effect of graphene and the carbon nanotubes is exerted, and a conductive network is efficiently constructed. The master batch can be blended with variouspolymers, a conductive filler in the prepared composite material is uniformly distributed, and the conductivity is obviously improved. And the use amount of the carbon nanotube / graphene can be greatly reduced.

Owner:北京航天凯恩新材料有限公司 +2

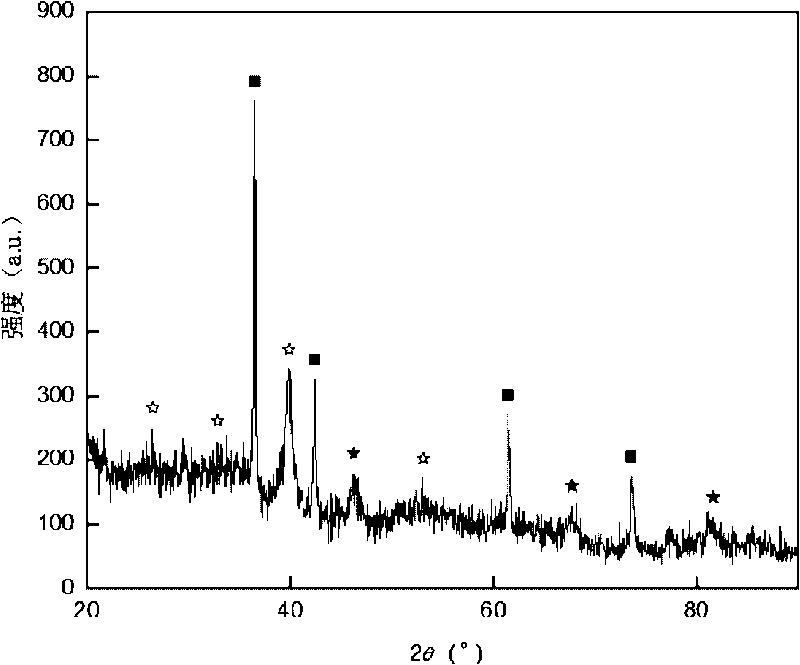

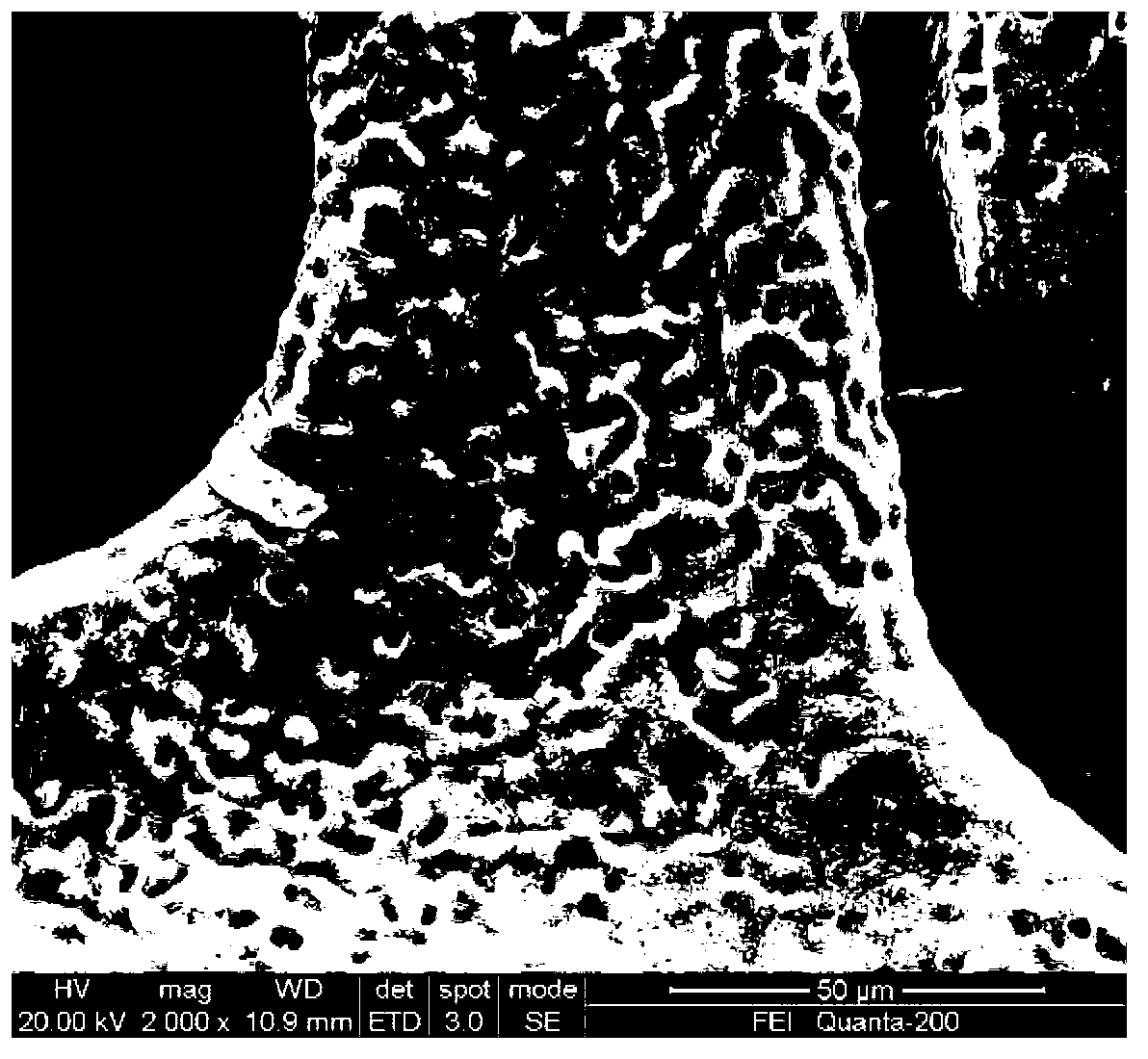

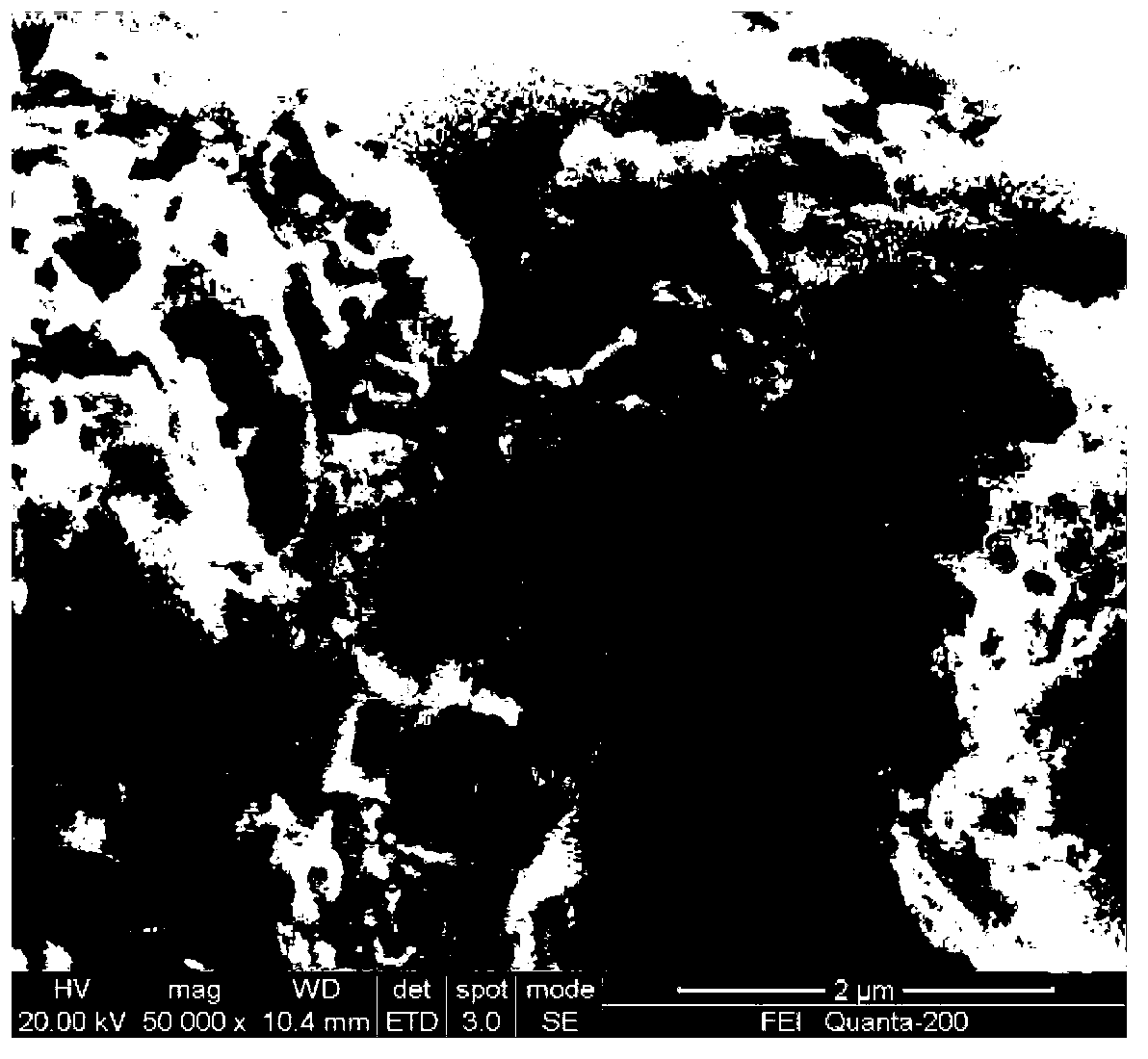

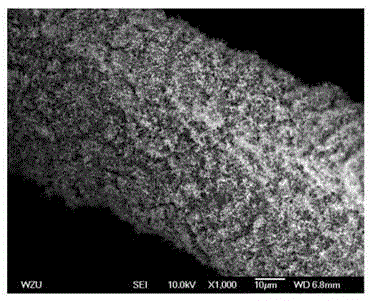

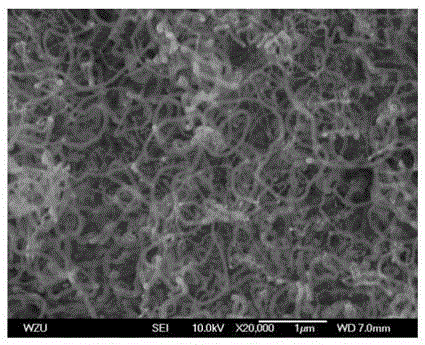

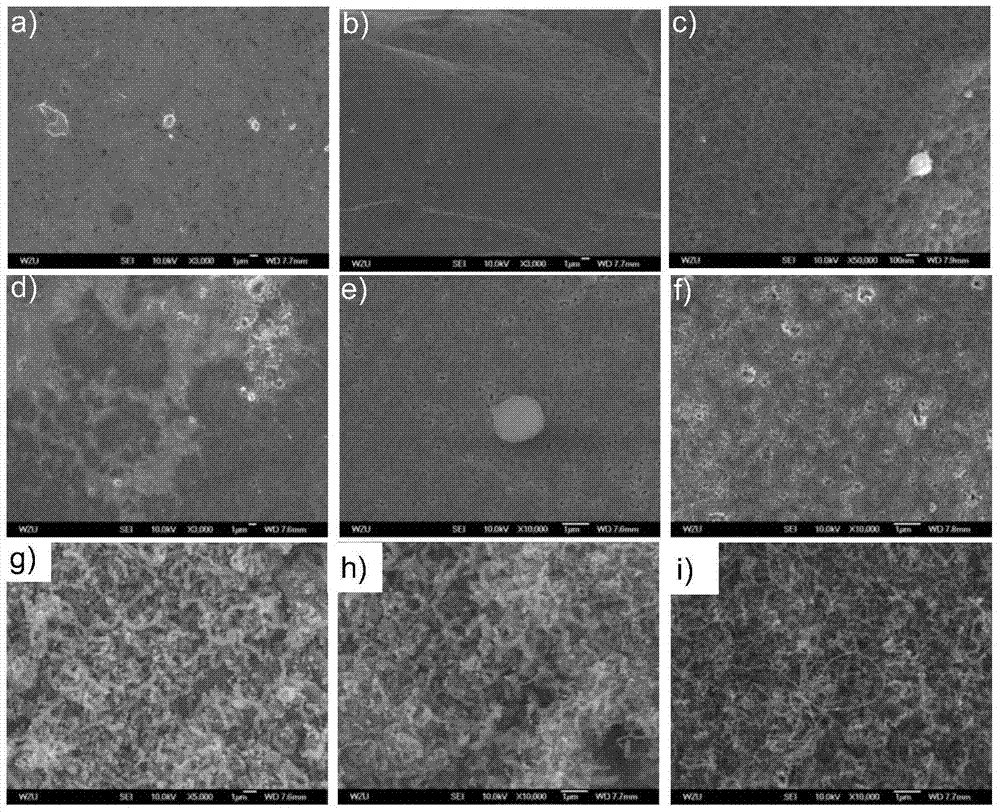

A method for electroless copper plating of multi-walled carbon nanotubes

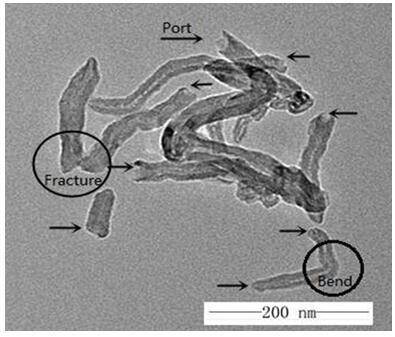

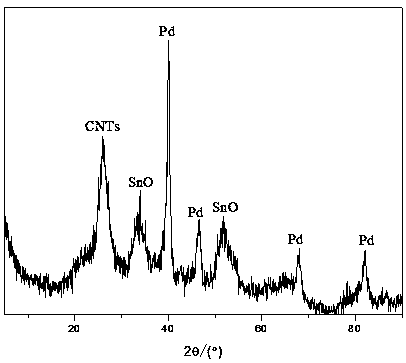

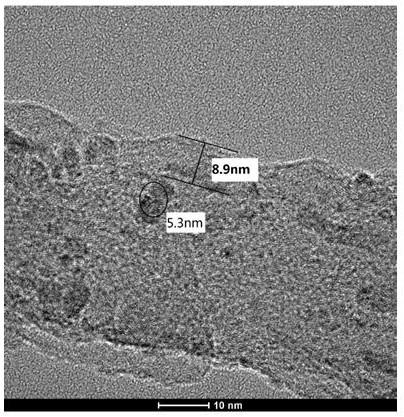

ActiveCN107460458BSmall aspect ratioEasy reunionTransportation and packagingMetal-working apparatusLongest DiameterCopper plating

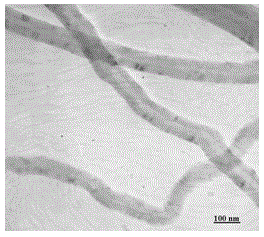

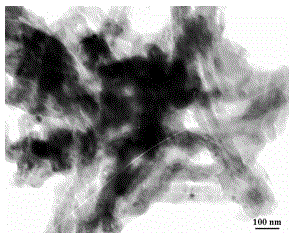

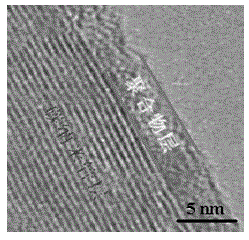

The invention discloses a method for electroless copper plating of multi-walled carbon nanotubes, which belongs to the technical field of carbon nanotube modification; the invention uses long-time high-energy ultrasonic oscillation to short-cut multi-walled carbon nanotubes to reduce the aspect ratio and open ports; After purification, sensitization, activation, and secondary activation modification, the copper layer is continuously plated on the inner and outer walls of the multi-walled carbon nanotubes with small aspect ratio by using an electroless plating method. The method of the invention is efficient and controllable, effectively reduces the aspect ratio of multi-walled carbon nanotubes, and simultaneously coats the inner and outer walls of multi-walled carbon nanotubes with a copper layer; the plated copper layer has high purity, uniform and continuous coverage, and solves the problem The problem of agglomeration of tubes in the copper matrix, poor wettability, and low interfacial bonding strength provides a better reinforcement for the preparation of high-strength, high-conductivity carbon nanotube-reinforced copper-based composites.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of electronic cigarette oil-leading rope with carbon nanotube-graphite synergetic enhancement

ActiveCN105544007ARaw materials are easy to getThe synthesis steps are simpleMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberModified carbon

The invention discloses an electronic cigarette oil-leading rope with carbon nanotube-graphite synergetic enhancement, and a preparation method thereof. The preparation method comprises the following steps of adopting glass fiber as a raw material, using a modified carbon nanotube to modify the glass fiber, and carrying out coupling treatment, so that the carbon nanotube is chemically grafted on the glass fiber to obtain the glass fiber with carbon nanotube enhancement; on the other hand, homogenizing and smashing graphite materials, coupling the surface, and then adding into resin of a polymer to form slurry of the glass fiber; performing blend spinning the glass fiber with carbon nanotube enhancement with graphite-added resin to obtain the glass fiber / polymer composite fiber with carbon nanotube / graphite synergetic enhancement, and interwinding to form the electronic cigarette oil-leading rope. According to the electronic cigarette oil-leading rope provided by the invention, the preparation process is simple and convenient, the problems of poor elasticity, fragility, easiness in breaking, poor abrasion resistance and the like of the traditional oil-leading rope are well solved, meanwhile, the heat transmission capacity is also enhanced, and the phenomenon that an electronic cigarette element is damaged due to dry ashing is avoided.

Owner:CHINA TOBACCO GUANGXI IND

Conductive nylon masterbatch with graphene-carbon nanotube composite structure and preparation method thereof

ActiveCN112029273BImprove mechanical propertiesAccurate and controllable loadPolymer sciencePolymer chemistry

The invention provides a conductive nylon masterbatch of a graphene-carbon nanotube composite structure, which uses nylon as a carrier, and after carbon nanotubes and graphene are grafted and modified, they are connected by chemical bonding to form a composite structure, which is loaded on on a nylon carrier. The conductive nylon masterbatch provided by the present invention first carries out carbon nanotube and graphene surface grafting treatment, and then through the amino group grafted on the carbon nanotube surface and the glycidyl ether oxygen group grafted on the graphene surface Carry out ring-opening reaction, chemically combine graphene and carbon nanotubes, and finally prepare conductive masterbatch. While the carbon nanotube-graphene composite structure is well dispersed in the polymer, the graphene and carbon nanotubes can also be fully overlapped to give full play to the synergistic effect of the two to efficiently build a conductive network. The masterbatch can be blended with various polymers, and the conductive filler in the prepared composite material is evenly distributed, and the conductive performance is obviously improved. Can greatly reduce the amount of carbon nanotubes / graphene.

Owner:北京航天凯恩新材料有限公司 +2

Method for preparing in-situ growing carbon nano tube chemical decoration electrode

InactiveCN1987443BIncrease response currentHigh sensitivityMaterial electrochemical variablesCarbon nanotubeElectrochemistry

Owner:SOUTHWEST JIAOTONG UNIV

Conductive material and manufacturing method thereof

ActiveUS8288506B2Increase resistanceEasy to prepareLiquid surface applicatorsPlastic/resin/waxes insulatorsConductive coatingCarbon nanotube

Disclosed is a method of manufacturing a conductive coating film having superior chemical resistance or solvent resistance and durability by chemically bonding a resin having an amine group (—NH2) with carbon nanotubes having a carboxyl group (—COOH). The conductive material having high bondability with carbon nanotubes and superior electrical properties includes carbon nanotubes uniformly contained therein, and thus has appropriate surface resistivity, and thereby can be used for antistatic, electrostatic dissipation and electromagnetic shielding purposes and in transparent or opaque electrodes depending on the resistivity value.

Owner:KOLON IND INC

Dendrimer-rare earth complex/carbon nanotube composite material and its synthesis method

The present invention relates to a dendrimer-rare earth complex / carbon nano-tube composite material and a synthesis method thereof. According to the method, a two-step click chemical reaction is adopted to sequentially modify a dendrimer and a plurality of functional groups on the surface of carbon nano-tubes, and then coordination of the functional groups on the surface of the carbon nano-tubes and one or a plurality of types of earth ions is adopted to prepare the dendrimer-rear earth complex / carbon nano-tube composite material. The nanometer composite material has good thermal stability and good dispersity in commonly used organic solvents, wherein rear earth has a certain fluorescence characteristic, such that the material can be widely used in a plurality of fields of absorption, catalysis, imaging, optoelectronic devices and the like.

Owner:ANKANG UNIV

Three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and preparation method thereof

InactiveCN103022450BImprove cycle performanceStrengthen the mechanical connectionElectrolytic coatingsCell electrodesTinningCarbon nanotube

The invention discloses a three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and a preparation method thereof. The preparation method of the three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode comprises the following steps: firstly, chemically plating carbon nanotubes with a nickel layer of a certain thickness; secondly, uniformly dispersing nickle-plated CNTs (carbon nanotubes) into a tin-plating solution; thirdly, taking foamy copper as a current collector (a plating substrate), sequentially compositely plating a CU-(CNTs-Ni) composite plating layer with the thickness of 1-3 microns, and plating an Sn-(CNTs-Ni) composite plating layer with the thickness of 0.1-3 Mum; and finally, performing thermal treatment to obtain a three-dimensional composite network alloy electrode. The alloy negative electrode has the first discharge specific capacity of 620mAh / g, and after 200cycles, the specific capacity is attenuated by only 3-5%; the preparation method is simple in process; and the prepared alloy negative electrode is excellent in performance and is applicable to large-scale industrial production.

Owner:XIANGTAN UNIV

A carbon nanotube-graphite synergistically reinforced electronic cigarette oil guide rope preparation method

ActiveCN105544007BRaw materials are easy to getThe synthesis steps are simpleMelt spinning methodsConjugated synthetic polymer artificial filamentsGlass fiberFiber

The invention discloses an electronic cigarette oil-leading rope with carbon nanotube-graphite synergetic enhancement, and a preparation method thereof. The preparation method comprises the following steps of adopting glass fiber as a raw material, using a modified carbon nanotube to modify the glass fiber, and carrying out coupling treatment, so that the carbon nanotube is chemically grafted on the glass fiber to obtain the glass fiber with carbon nanotube enhancement; on the other hand, homogenizing and smashing graphite materials, coupling the surface, and then adding into resin of a polymer to form slurry of the glass fiber; performing blend spinning the glass fiber with carbon nanotube enhancement with graphite-added resin to obtain the glass fiber / polymer composite fiber with carbon nanotube / graphite synergetic enhancement, and interwinding to form the electronic cigarette oil-leading rope. According to the electronic cigarette oil-leading rope provided by the invention, the preparation process is simple and convenient, the problems of poor elasticity, fragility, easiness in breaking, poor abrasion resistance and the like of the traditional oil-leading rope are well solved, meanwhile, the heat transmission capacity is also enhanced, and the phenomenon that an electronic cigarette element is damaged due to dry ashing is avoided.

Owner:CHINA TOBACCO GUANGXI IND

Carbon nanotube chemical molecular detection sensor and method for making same

InactiveCN1306264CHigh sensitivityRealize the recognition functionMaterial analysis using wave/particle radiationSolid-state devicesNanotubeChemistry

The invention relates to a device and method for sensing detecting the chemistry molecule through the carbon nanometer tube. The device fits the single wall carbon nanometer tube on the substrate, on end of the tube deposits the base point electrode, deposits the coherent electrode on the place where the distance from the other end of the tube is the coherence length of the tube, the base point electrode and the coherent electrode are connected with the detector through the external electrode set on the substrate or connected directly, the tube has the protective coating while the unsupported is exposed as the sensing probe. The making method is: setting the single wall carbon nanometer tube scatter on the insulated substrate, preparing metal base point electrode in one end, depositing metal coherence electrode and two metal external electrodes whose area is micron size in the other end, and connects with the base point electrode and coherence electrode individually.

Owner:UNIV OF SCI & TECH OF CHINA

Process for derivatizing carbon nanotubes with diazonium species and compositions thereof

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or pre-formed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

Preparation method of electronic cigarette oil guide rope enhanced by carbon nanotube interface

ActiveCN105544006BRaw materials are easy to getThe synthesis steps are simpleConjugated synthetic polymer artificial filamentsFiberGlass fiber

The invention discloses an electronic cigarette oil-leading rope with carbon nanotube interface enhancement, and a preparation method and a product thereof. The preparation method comprises the following steps of adopting glass fiber as a raw material, and using a carbon nanotube modified by mixed acid to modify the glass fiber, so that the carbon nanotube is chemically grafted on the glass fiber; processing through a coupling agent, performing blend spinning with resin to obtain glass fiber / polymer composite fiber with carbon nanotube interface enhancement, and interwinding to form the electronic cigarette oil-leading rope. The glass fiber / polymer composite fiber with carbon nanotube interface enhancement has favorable toughness and heat-transmission capacity, and the preparation process is simple and convenient. The electronic cigarette oil-leading rope provided by the invention not only well solves the problems of poor elasticity, fragility and easiness in breaking of the traditional oil-leading rope, meanwhile, the heat transmission capacity is also enhanced, and the phenomenon that an electronic cigarette element is damaged due to dry ashing is avoided.

Owner:CHINA TOBACCO GUANGXI IND

A variety of carbon materials doped with high thermal conductivity silicone adhesive and preparation method thereof

ActiveCN105419724BImprove thermal conductivityImprove stabilityNon-macromolecular adhesive additivesFiberCarbon nanotube

The invention discloses a high-thermal-conductivity organic silicon adhesive doped with multiple carbon materials and a preparation method of the adhesive, relates to an organic silicon adhesive and a preparation method thereof, and aims to solve the problem that an existing organic silicon adhesive is lower in heat conductivity coefficient. The adhesive is prepared from silicone rubber, silicone oil, carbon powder, short carbon fiber, carbon nano tubes, a surfactant, a silane coupling agent, an alkynol inhibitor and an organic solvent. The method comprises the steps of 1, weighing the silicone rubber, the silicone oil, the carbon powder, the short carbon fiber, the carbon nano tubes, the surfactant, the silane coupling agent, the alkynol inhibitor and the organic solvent; 2, chemically grafting the carbon nano tubes to the short carbon fiber; 3, performing surface treatment on a thermally conductive filler; 4, mixing the silicone rubber and the silicone oil evenly by an open mill, then adding the thermally conductive filler obtained in step 3 via a three-roller grinder, mixing evenly, and then mixing the silane coupling agent, the alkynol inhibitor and the organic solvent, thus obtaining the high-thermal-conductivity organic silicon adhesive. The method is used for preparing the organic silicon adhesive.

Owner:HARBIN INST OF TECH

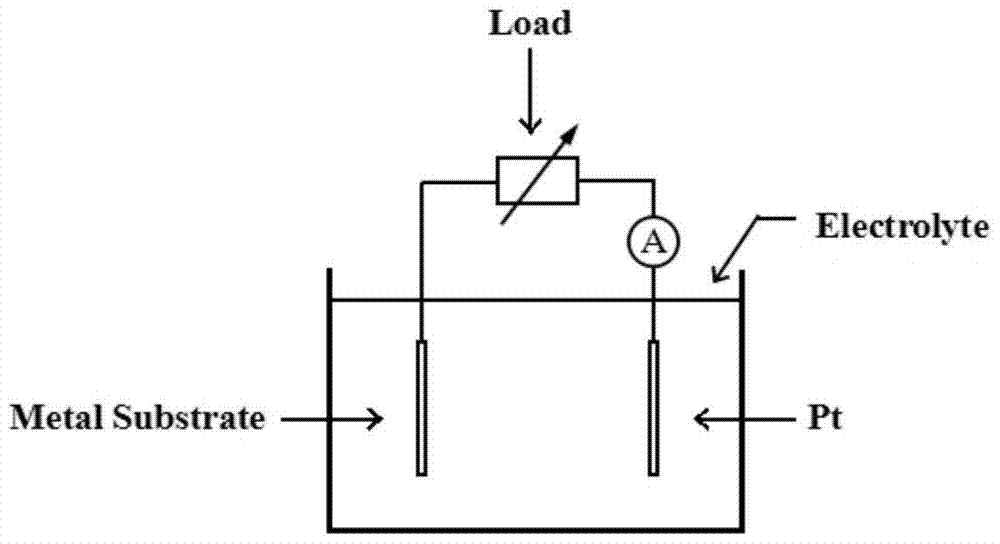

A kind of anodization process of metal substrate for carbon nanotube growth

ActiveCN104651899BImprove conductivityImprove thermal conductivityAnodisationChemical vapor deposition coatingMetal particleThermal contact

The invention discloses an anodization process for a metal substrate used for carbon nanotube growth. The metal substrate is a metal substrate containing a catalytic metal for carbon nanotube chemical vapor deposition reaction, and the catalytic metal is iron, cobalt or nickel The process steps include: the positive electrode of the DC power supply is connected to the metal substrate to form the anode, and other conductive substrates are used as the cathode, and both electrodes are immersed in the electrolyte to form a circuit. The electrolyte is a solution of acid, alkali, and salt. Form a dense, uniform porous structure. The process of the invention makes the natural points on the surface of the metal substrate suitable for the growth of carbon nanotubes uniform and increased, so that the metal substrate can provide catalytic particles of uniform nanoscale size at high temperature, and when it is applied to the growth of carbon nanotubes, the carbon nanotubes grow from The surface integrated with the metal substrate evenly grows on the catalyst metal particles, which effectively increases the bonding force, reduces the contact resistance and thermal resistance, and improves the electrical and thermal conductivity of the carbon tube.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com