A method for electroless copper plating of multi-walled carbon nanotubes

A technology of multi-walled carbon nanotubes and electroless copper plating, which is applied in liquid chemical plating, transportation, packaging, coating, etc., and can solve problems such as substrate wetting and bonding, large aspect ratio of CNTs, and agglomeration that affect the coating effect , to achieve the effect of improving the agglomeration phenomenon, enhancing the strengthening effect and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of method for electroless copper plating on inner and outer tube walls of multi-walled carbon nanotubes, the specific steps include:

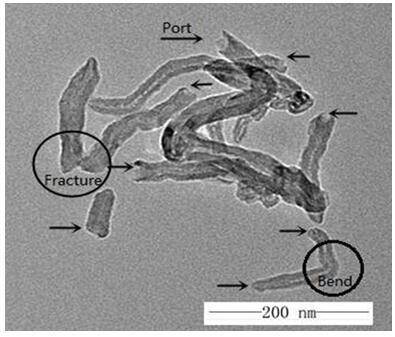

[0033] (1) Chopped: Add 2g of multi-walled carbon nanotubes to 1L of ethanol solvent (the solid-to-liquid ratio g:L of multi-walled carbon nanotubes to ethanol solvent is 2:1), add dispersant dimethylformamide 0.5 g / L, treated for 10 hours under ultrasonic conditions with an ultrasonic frequency of 10khz and a power of 80w, filtered, washed, and vacuum-dried at 80°C for 10h; the length of the original MWCNTs is micron-scale and the ports are in a closed state, and most MWCNTs interact with each other Intertwined and intertwined to form agglomerates, with defects and kinks on the surface, the morphology of MWCNTs after high-energy ultrasonic vibration chopping is as follows: figure 1 shown, from figure 1 It can be seen that the bending and kinks of CNTs begin to break, and the fracture is open in an irregular state (...

Embodiment 2

[0039] Embodiment 2: a method for electroless copper plating on inner and outer tube walls of multi-walled carbon nanotubes, the specific steps include:

[0040] (1) Chopped: Add 5g of multi-walled carbon nanotubes to 1L of methanol solvent (the solid-to-liquid ratio g:L of multi-walled carbon nanotubes to ethanol solvent is 5:1), add the dispersant N-methylpyrroline 0.8g / L, treated for 12 hours under ultrasonic frequency of 20khz, power of 130w, filtered, washed, and vacuum dried at 80°C for 10h;

[0041] (2) Purification: Add the chopped multi-walled carbon nanotubes in step (1) to the methyl ethyl ketone solvent according to the solid-to-liquid ratio g:L of 5:1, and disperse them under ultrasonic conditions with an ultrasonic frequency of 20khz and a power of 130w Treat for 2 hours, filter, wash, and vacuum dry at 80°C for 10 hours; add the dispersed multi-walled carbon nanotubes to the concentrated acid solution according to the solid-to-liquid ratio g:L of 5:1 (concentrat...

Embodiment 3

[0046] Embodiment 3: a method for electroless copper plating on inner and outer tube walls of multi-walled carbon nanotubes, the specific steps include:

[0047] (1) Chopped: Add 8g of multi-walled carbon nanotubes to 1L of ethylene glycol solvent (the solid-to-liquid ratio g:L of multi-walled carbon nanotubes to ethanol solvent is 8:1), add dispersant dimethyl formazan Amide 0.5g / L, gelatin 1.0g / L, treated under ultrasonic frequency of 30khz, power of 160w for 13 hours, filtered, washed, vacuum dried at 80°C for 10h;

[0048] (2) Purification: Add the multi-walled carbon nanotubes chopped in step (1) to the cyclohexanone solvent according to the solid-to-liquid ratio g:L of 8:1, under the ultrasonic conditions of 30khz ultrasonic frequency and 160w power Disperse for 4 hours, filter, wash, and vacuum dry at 80°C for 10 hours; add the dispersed multi-walled carbon nanotubes to the concentrated acid solution according to the solid-to-liquid ratio g:L of 8:1 (concentrated acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com