Carbon nanotube chemical molecular detection sensor and method for making same

A technology of carbon nanotubes and chemical molecules, which is applied in the field of nano-detection and sensing, can solve problems such as the inability to realize single-molecule detection and identification, complex manufacturing processes, etc., and achieve the effects of guaranteed sensitivity, recognition function, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

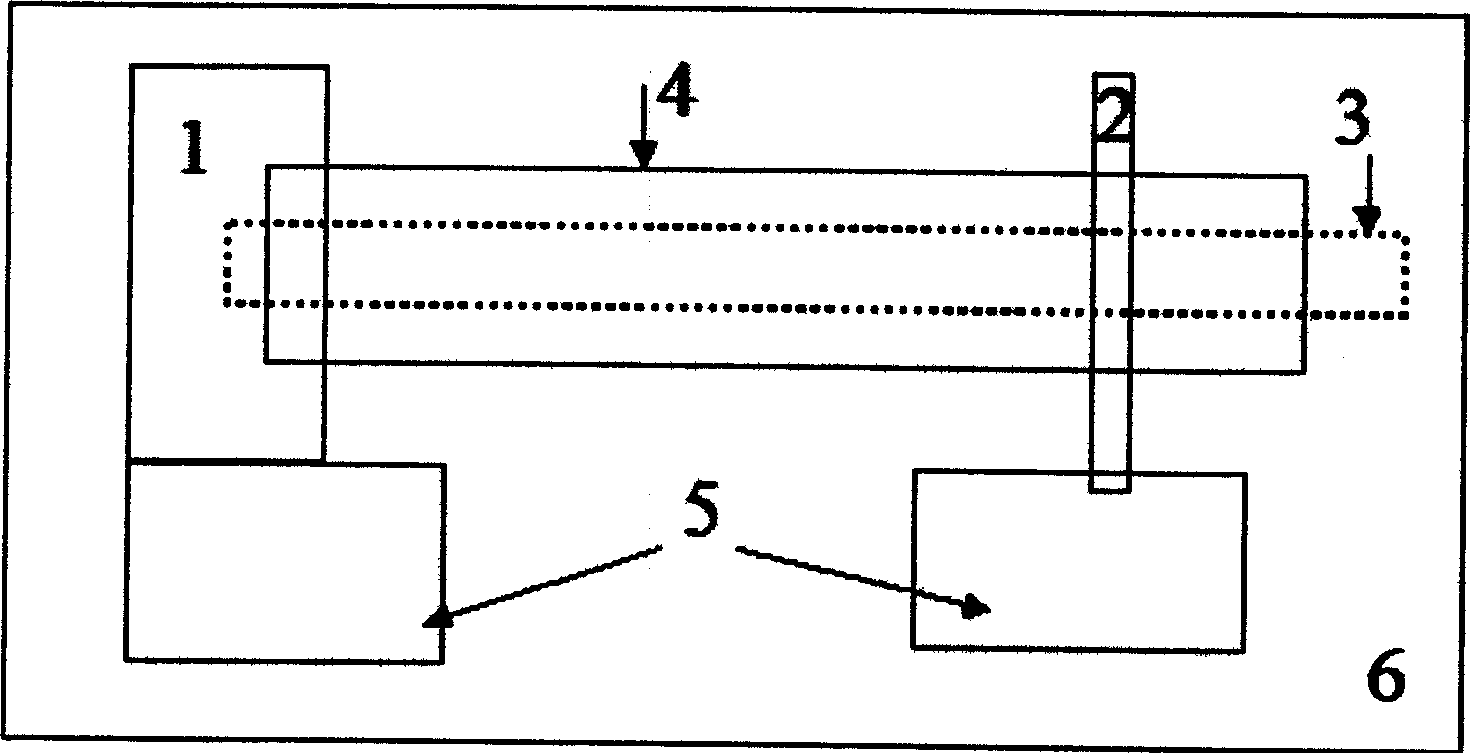

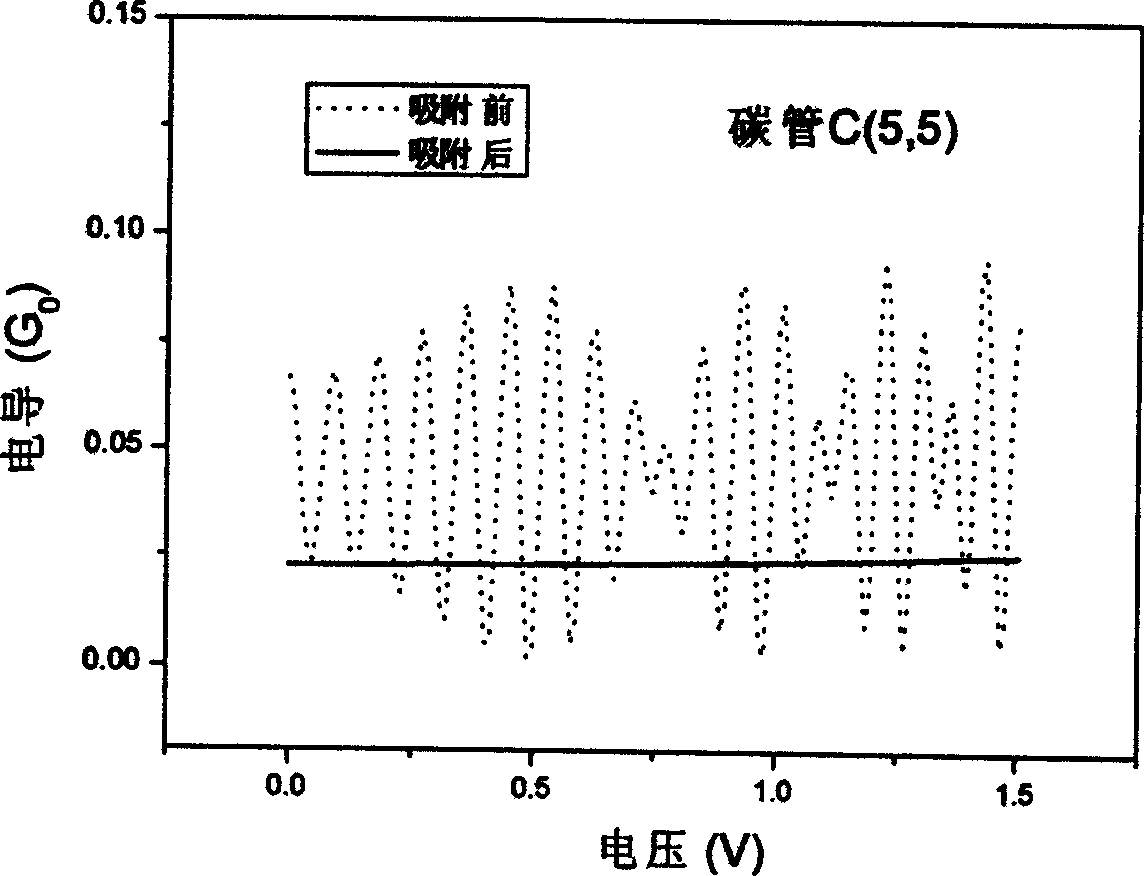

[0024] 1) Disperse open single-walled carbon nanotubes with a length of about 3 microns and a structure of C(5,5) in an ethanol solution, and after ultrasonic treatment for 1 minute, drop a little mixed solution onto a silica substrate, After the ethanol volatilizes naturally, the carbon tubes remain on the substrate, and there are about 1 to 2 carbon nanotubes within a range of 10 square microns;

[0025] 2) Use a microscope to find out one of the carbon nanotubes that is not connected or in contact with other carbon tubes, and use electron beam lithography to prepare a base point electrode made of metal at one end of the carbon nanotube. The metal of the electrode can be divided into two layers for better Good adhesion and conductivity, in the present embodiment, first deposit 10 nanometers of thick titanium (Ti), and then deposit 50 nanometers of gold (Au), the width of the base point electrode on the nanotube is about 300 nanometers, and the nanometer The fracture at one e...

Embodiment 2

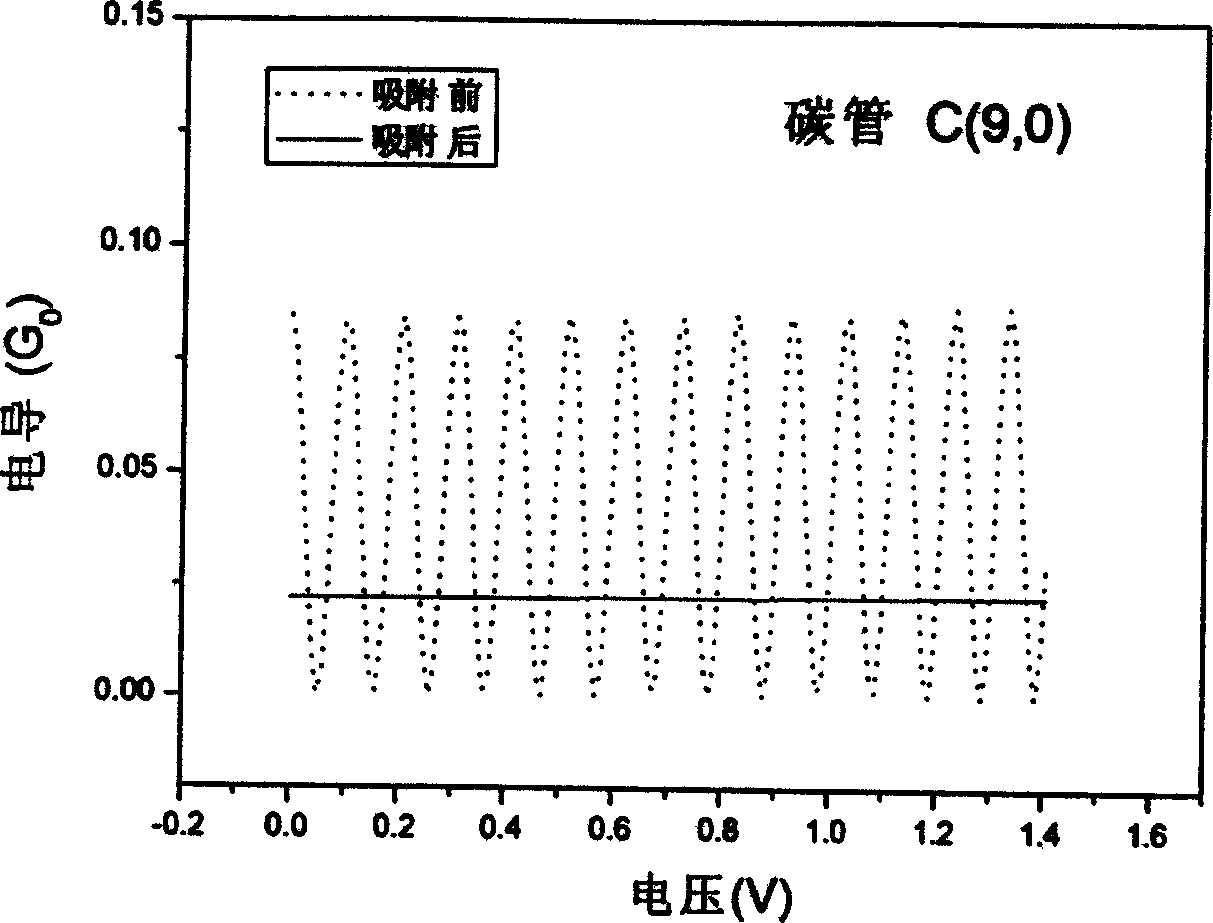

[0032] 1) Disperse open single-walled carbon nanotubes with a length of about 3 microns and a structure of C(9,0) in an ethanol solution. After ultrasonic treatment for 1 minute, drop a small amount of the mixed solution onto the mica substrate, and wait for ethanol to After natural volatilization, the carbon tubes remain on the substrate, and there are about 1 to 2 carbon nanotubes within a range of 10 square microns;

[0033] 2) Use a microscope to find out one of the carbon nanotubes that is not connected or in contact with other carbon tubes, and use electron beam lithography to prepare a base point electrode made of metal at one end of the carbon nanotube. The metal of the electrode is also divided into two layers. Deposit chromium (Cr) with a thickness of 10 nanometers, and then deposit 50 nanometers of gold (Au), the width of the electrode on the nanotube is about 1 micron, and the fracture of one end of the nanotube is completely covered, and the other end is suspended;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com