Dendrimer-rare earth complex/carbon nanotube composite material and its synthesis method

A technology of dendritic polymers and rare earth complexes, which is applied in the field of polymer composite materials, can solve problems such as differences in complexation selectivity, achieve good thermal stability and dispersion, and broaden the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A synthetic method of a dendrimer-rare earth complex / carbon nanotube composite material, comprising the following steps:

[0028] (1) Carbon nanotubes are dissolved in tris hydrochloride buffer solution of dopamine (0.5~5g / L) at 20~35 o Disperse at C, stir at 100~300 rpm, react for 8~24 hours, wash twice with deionized water after separation, then add to the aqueous solution of propargylamine (1~3g / L), and react again under stirring at room temperature 2 to 6 hours, centrifuged and washed 4 times with deionized water, and vacuum dried at room temperature to obtain alkyne-functionalized carbon nanotubes;

[0029] (2) In the mixed solvent of pyridine and dichloromethane, add 4-diaminopyridine, 1-azido-hexanol and isopropylidene- 2,2-bis(methoxy)propionic acid, at 20~50 o After reacting for 12 to 16 hours under C conditions, add methanol and DOWEX50W-X2-200 ion exchange resin to it, continue to react at the same temperature for 4 to 8 hours, filter and evaporate the solv...

Embodiment 1

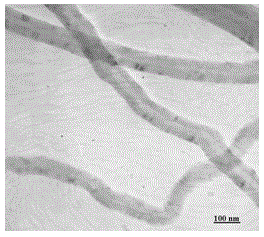

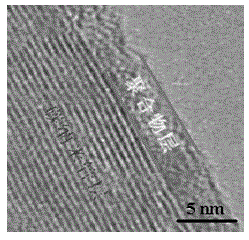

[0036] (1) Alkyne-functionalized multi-walled carbon nanotubes

[0037] In a 50mL round-bottomed flask, add 2g of multi-walled carbon nanotubes and 10mL of dopamine (1mg / mL) tris hydrochloride buffer, react at room temperature for 12 hours, then centrifuge, wash twice with deionized water, Then dispersed in an aqueous solution of propargyl amine (1 mg / mL), stirred at room temperature for 5 hours, separated and washed 4 times with deionized water, and vacuum-dried at room temperature to obtain alkyne-functionalized multi-walled carbon nanotubes.

[0038] (2) Generation 4.0 dendrimers with 16 hydroxyl groups

[0039] In 20 mL of a mixed solvent of pyridine and dichloromethane (v / v=1:1), add 4-diaminopyridine, 1-azido-hexanol and isopropylidene- 2,2-bis(methoxy)propionic acid, 25 o After C reacted for 12 hours, 30 mL of methanol and 5 g of DOWEX50WX2-200 ion exchange resin were added thereto, the reaction was continued for 8 hours at the same temperature, the filtrate was filte...

Embodiment 2

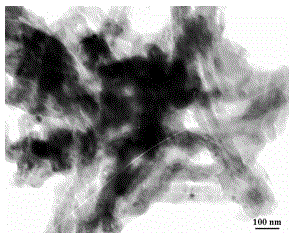

[0050] Alkyne-functionalized multi-walled carbon nanotubes, 16-hydroxyl 4.0-generation dendrimers, 16-hydroxyl 4.0-generation dendrimers modified multi-walled carbon nanotubes, 16-alkyne 4.0-generation dendrimers Molecularly modified multi-walled carbon nanotubes and multi-walled carbon nanotubes modified by 4.0 generation dendrimers of 16 carboxyl groups such as example 1 step (1), step (2), step (3), step (4) and step (5) Made.

[0051] Disperse 0.2g of 4.0 generation dendrimer-modified multi-walled carbon nanotubes with 16 carboxyl groups in 3mL of dichloromethane, add 0.1g of terbium trichloride and 0.09g of 8-hydroxyquinoline, 25 o Stirring and reacting at C for 5 hours, after separation, washing with methanol for 4 times, and vacuum drying at room temperature, the dendrimer-terbium complex / multi-walled carbon nanotube composite material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com