Method for preparing battery electrode by directly growing carbon nanotubes on foamed nickel substrate

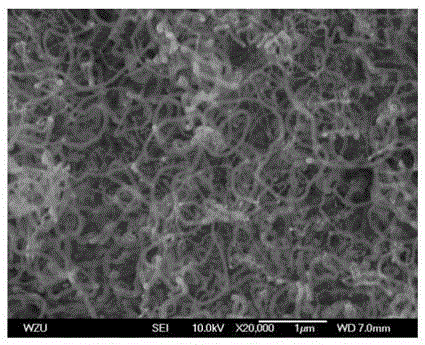

A carbon nanotube, battery electrode technology, applied in alkaline battery electrodes, electrode manufacturing, vapor deposition manufacturing and other directions, can solve problems affecting device performance and life, large heat dissipation, accelerated device aging, etc., to improve performance and Excellent service life, excellent electrical conductivity, and the effect of improving the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

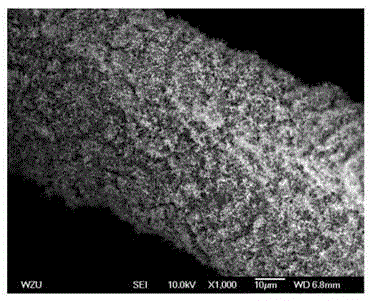

[0022] The method for directly growing carbon nanotubes on a nickel-containing metal substrate and preparing electrodes for nickel-metal hydride batteries in the CVD reaction device includes the following steps:

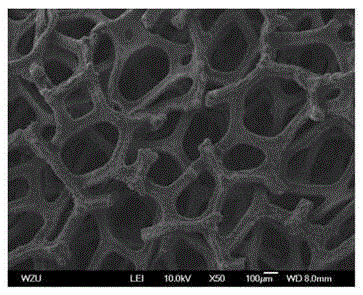

[0023] (1) Perform chemical and ultrasonic cleaning on the nickel-containing metal substrate. In this embodiment, the nickel-containing metal substrate is nickel foam;

[0024] (2) CVD reaction device is set, and in CVD reaction device, carry out the chemical vapor phase reaction growth of carbon nanotube to nickel-containing metal base, described CVD reaction device comprises quartz heating furnace, is arranged on the gas inlet channel of quartz heating furnace one side , and a vacuum pump arranged at the other end of the quartz heating furnace, the nickel-containing metal substrate is carried by a quartz tray and placed in the middle of the quartz heating furnace, and the quartz heating furnace is pumped to a vacuum state with a pressure <1 Torr by the vacuum pump, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com