Three-dimensional netted tin-copper-nickel-carbon nanotube alloy negative electrode and preparation method thereof

A technology of carbon nanotubes and three-dimensional mesh, which is applied in the direction of battery electrodes, metal material coating technology, liquid chemical plating, etc., can solve the problems of poor cycle performance of alloy negative electrode materials, and achieve high charge-discharge specific capacity, cycle powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (1) Carry out impurity removal and dispersion treatment on CNTs, select carbon nanotubes with an outer diameter of 10~20nm and a length of 1~3μm,

[0071] The steps for treating CNTs are as follows: first add HCl solution with a mass concentration of 18.25% into the container containing CNTs to obtain a pretreatment solution with a CNTs content of 2 g / L;

[0072] Then ultrasonically vibrate the above-mentioned pre-treatment liquid while mechanically stirring for 2 hours, then magnetically stir for 10 hours, then separate the CNTs from the pre-treatment liquid, and finally dry the CNTs for 24 hours;

[0073] (2) then adopt electroless plating to the nickel coating that CNTs plating thickness is 100nm,

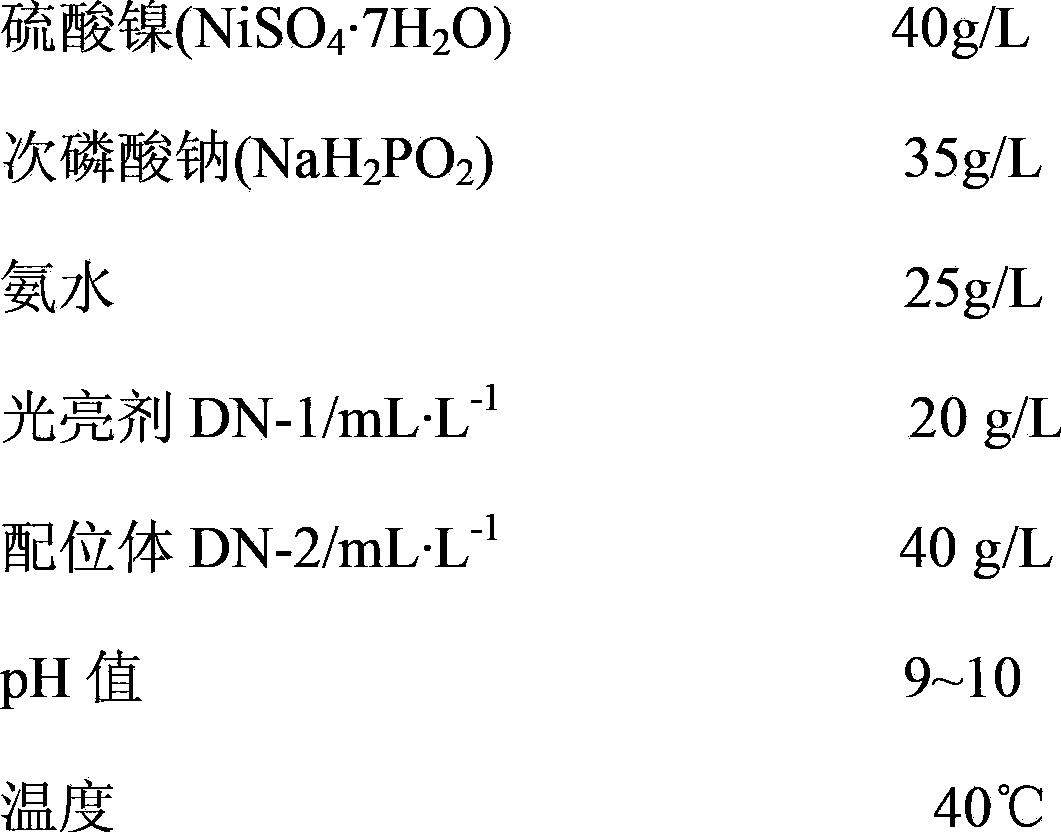

[0074] The formulation and conditions of electroless nickel plating are as follows:

[0075]

[0076] (3) Using the nickel-coated CNTs obtained in step (2), the Cu-(CNTs-Ni) composite coating with a thickness of 2 μm was plated on the copper foam with a specification ...

Embodiment 2

[0098] The rest of the steps are the same as in Example 1, using copper foam with a specification of 120PPI as the substrate, composite electroplating a Cu-(CNTs-Ni) composite coating with a thickness of 1 μm, and then composite electroplating a 2 μm Sn-(CNTs-Ni) alloy coating, and finally Heat treatment at 200°C for 10 hours to obtain a three-dimensional network tin-copper-nickel-CNTs alloy negative electrode. Using the conventional lithium-ion battery test method, the first discharge mass specific capacity of the negative electrode effective material is 587mAh / g. After 200 charging cycles, the specific capacity is still 563.5mAh / g. The specific capacity decays only 4%, and the Coulombic efficiency exceeds 96. %.

Embodiment 3

[0100] All the other steps are the same as in Example 1. Using copper foam with a specification of 120PPI as the substrate, composite electroplating with a Cu-(CNTs-Ni) composite coating with a thickness of 3 μm, and then electroplating a 2 μm Sn-(CNTs-Ni) coating by co-deposition, and finally heat treatment at 200 ° C for 2 hours A three-dimensional mesh tin-copper-nickel-CNTs alloy negative electrode is obtained. Using the conventional lithium-ion battery test method, the first discharge mass specific capacity of the negative electrode effective material is 607mAh / g. After 100 charging cycles, the specific capacity is still 588.8mAh / g. The specific capacity decays only 3%, and the Coulombic efficiency exceeds 97. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com