High-thermal-conductivity organic silicon adhesive doped with multiple carbon materials and preparation method of adhesive

A silicone adhesive, high thermal conductivity technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of low thermal conductivity of silicone adhesives, and achieve the effect of good stability and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

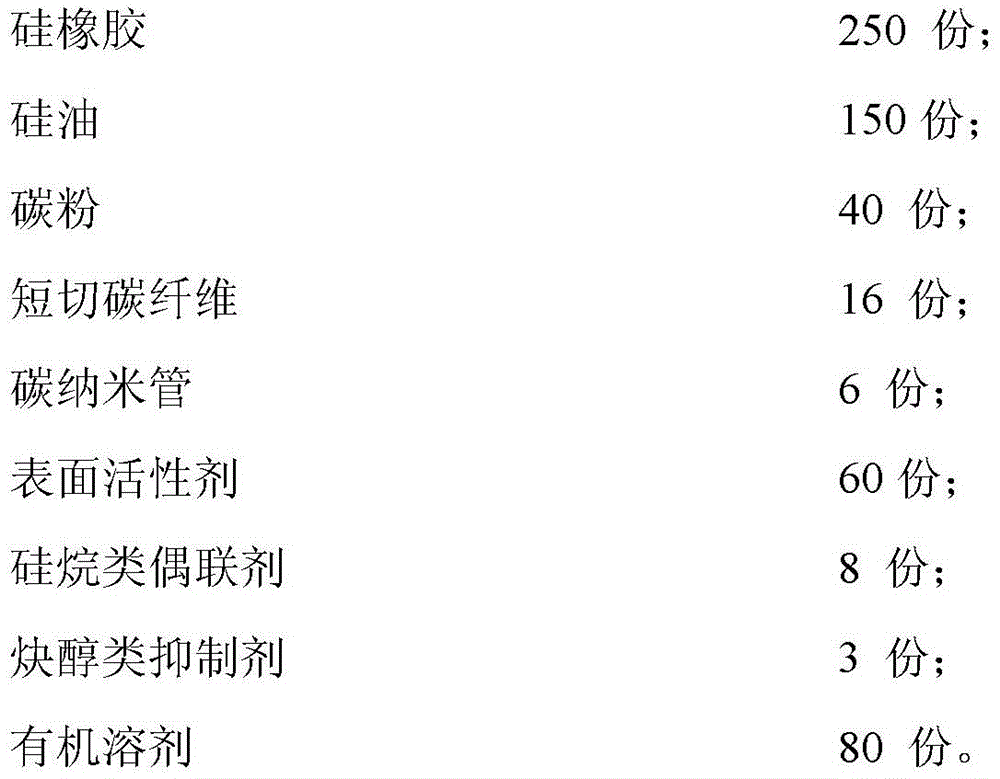

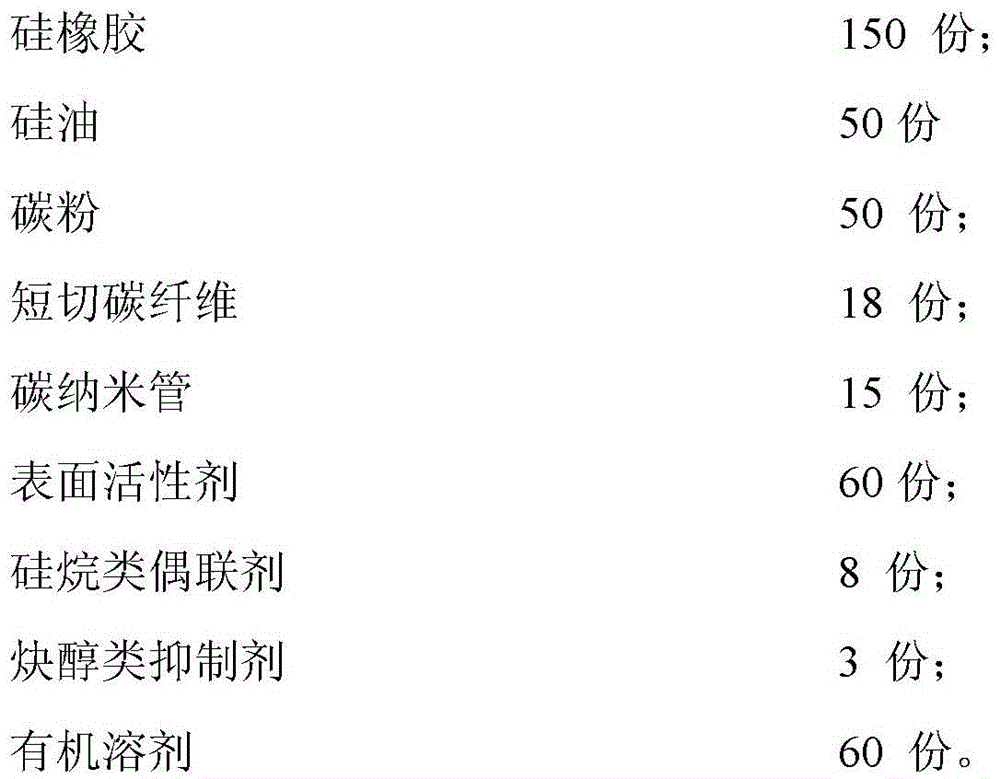

[0026] Specific Embodiment 1: In this embodiment, a variety of carbon materials doped with high thermal conductivity silicone adhesives include 150-250 parts by weight of silicone rubber, 50-150 parts of silicone oil, 30-50 parts of carbon powder, and 15-20 parts of chopped Carbon fibers, 6-16 parts of carbon nanotubes, 60-90 parts of surfactants, 8-11 parts of silane coupling agents, 2-4 parts of acetylenic alcohol inhibitors and 50-80 parts of organic solvents.

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that: the silicone rubber is methyl vinyl silicone rubber, wherein the vinyl content is 0.01%-3%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the silicone oil is a mixture of one or two of vinyl silicone oil and hydrogen-containing silicone oil in any ratio, and the vinyl group in vinyl silicone oil is The content is 0.01%-3%, and the hydrogen content in hydrogen-containing silicone oil is 0.05%-1.8%. Others are the same as in the first or second embodiment.

[0029] The vinyl content and hydrogen content in the present embodiment mean molar content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com