A carbon nanotube-graphite synergistically reinforced electronic cigarette oil guide rope preparation method

A carbon nanotube and oil-guiding rope technology, applied in the directions of melt spinning, conjugated rayon, fiber chemical characteristics, etc., can solve problems such as poor thermal conductivity, achieve broad market application prospects, avoid damage, and mechanical properties improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

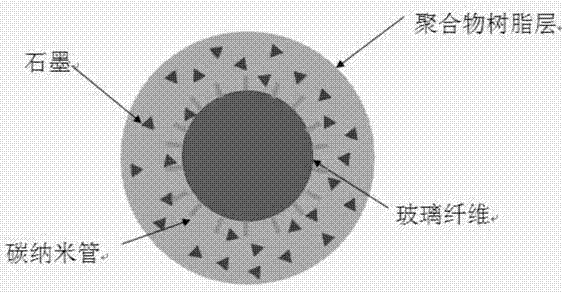

[0025] Example 1: A carbon nanotube / graphite synergistically enhanced electronic cigarette oil guide rope with an added amount of carbon nanotubes of 0.1% and an added amount of graphite of 20%, with a thermal conductivity of 5.42W / (m*k)

[0026] Disperse 2000g of glass fibers in a mixed solvent of water and ethanol, add 2g of carboxylated carbon nanotube material (100nm is truncated to 10nm after being acidified with mixed acid), and stir at 80°C for 24 hours, so that the carbon nanotubes above The groups fully react with the groups on the glass fiber; after the reaction, the unreacted carbon nanotubes are washed twice with deionized water, and dried at 100° C. to obtain carbon nanotube-modified glass fibers. 500g of flake high-carbon graphite material with an average particle size of 100μm, 20g of coupling agent, and ethanol as a solvent were used to disperse and react at a high speed of 25,000rpm for 8 hours at a temperature of 50°C, so that the original graphite material I...

Embodiment 2

[0027]Example 2: A carbon nanotube / graphite synergistically enhanced electronic cigarette oil guide rope with an added amount of carbon nanotubes of 0.5% and an added amount of graphite of 20%, with a thermal conductivity of 6.89W / (m*k)

[0028] Disperse 500g of glass fiber in a mixed solvent of water and ethanol, add 2.5g of carboxylated carbon nanotube material (1000nm is truncated to 100nm after being acidified with mixed acid), and stir at 50°C for 72 hours to make the carbon nanotube After the reaction, the unreacted carbon nanotubes were washed 4 times with deionized water, and dried at 60°C to obtain carbon nanotube-modified glass fibers. 500g of flake low-carbon graphite material with an average particle size of 1μm, 1g of coupling agent, and ethanol as a solvent were used to disperse and react at a high speed of 10,000rpm for 12 hours at a temperature of 70°C, so that the original graphite material It is broken down and becomes smaller (0.5 μm) and the surface is modi...

Embodiment 3

[0029] Example 3: A carbon nanotube / graphite synergistically enhanced electronic cigarette oil guide rope with an added amount of carbon nanotubes of 2.5% and an added amount of graphite of 20%, with a thermal conductivity of 8.98W / (m*k)

[0030] Disperse 500g of glass fiber in a mixed solvent of water and ethanol, add 12.5g of carboxylated carbon nanotube material (100nm is truncated to 10nm after being acidified with mixed acid), and stir at 100°C for 12 hours to make the carbon nanotube The groups on the glass fiber fully reacted with the groups on the glass fiber; after the reaction, the unreacted carbon nanotubes were washed three times with deionized water, and dried at 200°C to obtain carbon nanotube-modified glass fibers. 500g of expanded high-carbon graphite material with an average particle size of 500μm, 20g of coupling agent, and ethanol as a solvent were used to disperse and react at a high speed of 50,000rpm for 1 hour at a temperature of 50°C, so that the origina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com